Abstract

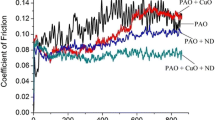

The tribological behaviors of the nano-diamond particles including the nano-diamond and the nano-diamond modified were studied at high temperature using SRV multifunctional test system. The worn steel surfaces were analyzed by means of X-ray photoelectron spectroscopy (XPS). The results show that nano-diamond particles can obviously improve the antiwear and friction reducing properties of the base oil at high temperature and the high load. The friction coefficient of the nano-diamond is very low at 200 °C when the test load is not more than 20 N. This tribological behaviors should attributed to the similarly to “ball bearing” lubrication action of the nano-diamond particles, so the movement between tribological pairs become sliding/rolling. The nano-diamond modified by dimer ester possesses excellent antiwear and friction reducing performance at 500 °C and load 500 N. The tribochemical reaction film between the nano-diamond particles and the renascent wear surface plays dominating lubrication role and the presence of the dimer ester on the rubbing surface can be propitious to form lubrication film containing nano-diamond on the worn surface at high temperature and high load.

Similar content being viewed by others

References

Hisakado T, Tsukizoe T, Yoshikawa H. Lubrication mechanism of solid lubricants in oils [J]. ASME Lubr Tech, 1983, 105(7): 245–253.

Reick F G. Energy saving lubricants coating colloidal PTFE[J]. ASME Lubr Tech, 1982, 38(5): 635–646.

Cusano C, Sliney H E. Dynamics of solid dispersions in oil during the lubrication of point contacts Part I: Graphite[J]. ASLE Trans, 1982, 25(1): 183–189.

Cusano C, Sliney H E. Dynamics of solid dispersions in oil during the lubrication of point contacts Part II: Molybdenum Disulfied [J]. ASLE Trans, 1982, 25(2): 190–197.

Bartz W J. Solid lubricant additives effect of concentration and other additives on anti-wear performance [J]. Wear, 1971,17(3): 422–432.

Savan A, Pfluger E, Goller R, et al. Use of nanoscaled multilayer and compound films to realize a soft lubrication phase within a hard, wear-resistant matrix[J]. Surface and Coating Technology, 2000, 126: 159–165.

Tarasov S, Kolubaev A, Belyaev S, et al. Study of friction reduction by nanocopper additives to motor oil [J]. Wear, 2002,252: 63–69.

QIAO Yu-lin, XU Bing-shi, MA Shi-nin, et al. Studies of the tribological properties and mechanism of the antifriction and repair additive containing nano-copper [J]. Petroleum Processing and Petrochemicals, 2003, 34(10): 38–43. (in Chinese)

CHEN Shuang, LIU Wei-min, OU Zhong-wen, et al. Trobological behavior of oleic ester coated PbO nanoparticles as additive in liquid paraffin [J]. Tribology 9, 2001, 21(5): 344–347. (in Chinese)

Liu W M, Chen S. The investigation of tribological behavior of surface-modified ZnS nanopartices in liquid paraffin [J]. Wear, 2000,238: 120–124.

ZHOU Jing-fang, WU Zhi-shen, ZHANG Zhi-jun, et al. Study on antiwear and pressure additive of surface coated LaF3 nanoparticles in liquid paraffin[J]. Wear, 2001, 249: 333–337.

Rapoport L, Leshchinsky V, Lapsker I, et al. Tribological properties of WS2 nanoparticles under mixed lubrication [J]. Wear, 2003, 255: 785–793.

Rapoport L, Leshchinsky V, Lvovsky M, et al. Superior tribological properties of powder materials with solid lubricant nanoparticles [J]. Wear, 2003, 255: 794–800.

Xu T, Zhao J Z, Xu K, et al. Study on the tribological properties of ultra-dispersed diamond containing soot as an oil additive [J]. STLE Transaction, 1997, 40(3): 178–189.

ZHANG Jia-xi, LIU Kun, HU Xian-guo. Effect of ultra-dispersed diamond nanoparticles as additive on the tribological properties of 15W/30 engine oil [J]. Tribology, 2002, 22(1): 44–49. (in Chinese)

QIAO Yu-lin, XU Bing-shi, MA Shi-nin, et al. The tribological properties of the composite additive containing nanometer diamond [J]. Petroleum Processing and Petrochemicals, 1999, 30(3): 12–15. (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (51489020605JS9105) supported by National Key Laboratory for Remanufacturing

Rights and permissions

About this article

Cite this article

Qiao, Yl., Sun, Xf., Xu, Bs. et al. High temperature tribological behaviors of nano-diamond as oil additive. J Cent. South Univ. Technol. 12, 181–185 (2005). https://doi.org/10.1007/s11771-005-0036-7

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0036-7