Abstract

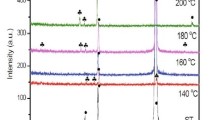

The effects of heat treatment on the microstructure and mechanical properties of two alloys, namely Al-12.2% Zn-2.48% Cu-2.0% Mg-0.15% Zr-0.166% Ag (alloy 1), and Al-9.99% Zn-1.72% Cu-2.5% Mg-0.13% Zr (alloy 2) were investigated. The results show that low temperature aging after promotive solution treatment can increase elongation without the loss of strength for the studied alloys. The optimum aging treatment (T6) for alloy 1 and alloy 2 is 100 °C/80 h and 100 °C/48 h, respectively. Compared with other heat treatment alloys, alloy 1 and alloy 2 show super-high tensile strength up to 753 MPa and 788 MPa, remaining 9.3% and 9.7% elongation under T6 condition, respectively. During aging, trace addition of Ag enhances the formations of GP zone and metastable phase, and stabilizes GP zone and metastable phase to a higher temperature. Trace addition of Ag prolongs the aging time of reaching the peak strength and delays over-aging condition of the alloy. However, trace addition of Ag promotes the formation of coarse constituent in the alloy and consumes hardening alloying elements of Zn and Mg. Morecover, the addition of the transition element Zr in 7000 series super-high alloy forms incoherent Al3Zr dispersoid which can serve as nucleation sites for nonuniform precipitation of η phase during aging process. The higher the aging temperature, the greater the tendency for nonuniform precipitation of η phase.

Similar content being viewed by others

References

Heinz A, Haszler A, Keidel C. Recent development in aluminium alloys for aerospace applications[J]. Materials Science and Engineering, 2000, A280(1): 102–107.

Mondolfo L F. Microstructure and property in aluminum alloy[M]. WANG Zhu-tang. Beijing: Metallurgical Industry Press, 1976.

Pickens J R. Aluminum powder metallurgy technology for high-strength applications[J]. J Mater Sci, 1981, 16(6): 1437–1442.

Osamura K. Mesoscopic structure of super-high strength P/M Al-Zn-Mg-Cu alloys[J]. Mater Sci Forum, 1996, 217–222(3): 1829–1834.

ZHANG Qing, CUI Jian-zhong, LU Gui-min. Experimental investigation on surface meniscus shape under effect of electromagnetic field with low frequency of 7075 aluminum alloy produced by CREM process[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(s): 109–116. (in Chinese)

ZHANG Kun, LIU Zhi-yi, FENG Chun. The effect of small addition of silver on the microstructure and mechanical properties of a high-zinc super-high strength aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 116–122. (in Chinese)

Polmear I J. A trace element effect in alloys based on the aluminum-zinc-magnesium system [J]. Nature, 1960(186): 303–304.

Macchi C E. Influence of small addition of Ag on the ageing kinetics of an Al-Zn-Mg alloy: a positron annihilation study[J]. Mater Sci Forum, 2002, 396–402(2): 833–838.

Maloney S K. The effects of a trace addition of silver upon elevated temperature ageing of an Al-Zn-Mg alloy [J]. Micron, 2001, 32: 741–747.

Lee C W. The effect of silver addition on 7055 Al alloy[J]. Materials & Design, 1997, 18(4–6): 327–332.

ZHANG Kun, LIU Zhi-yi. The evolution of undissolved phases in the high-zinc super-high strength aluminum alloy during ageing [J]. Transactions of Nonferrous Metals Society of China, 2004, 14(2): 356–361.

Fulideangjieer. Structure of deformation aluminum alloys[M]. YAO Zhong-xia. Chongqing: Chongqing Science and Technology Press, 1989. (in Chinese)

Godard D, Archambault P. Precipitation sequences during quenching of the AA7010 alloy[J]. Acta Materialia, 2002, 50: 2319–2329.

CHEN Kang-hua, LIU Hong-wei. Effect of promotively solutionizing heat treatment on the mechanical properties and fracture behavior of Al-Zn-Mg-Cu alloys[J]. Acta Metallurgica Sinica, 2001, 37(1): 29–33.

Kanno M. Precipitation behavior of 7000 alloys during retrogression and reaging treatment[J]. Material Science and Technology, 1994, 10(6): 599–603.

Hono K. Atom probe study of the precipitation process in Al-Cu-Mg-Ag alloys[J]. Acta Metall Mater, 1993, 41(3): 829–838.

QU Bin-lung, YANG Ji-gang. Effects of step quench and aging on mechanical properties and resistance to stress corrosion cracking of 7050 aluminum alloy[J]. Material Transactions JIM, 2000, 41(7): 783–789.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (2001AA332030) supported by the National High Technology Research and Development Program of China

Rights and permissions

About this article

Cite this article

Feng, C., Liu, Zy., Ning, Al. et al. Effect of low temperature aging on microstructure and mechanical properties of super-high strength aluminum alloy. J Cent. South Univ. Technol. 13, 461–467 (2006). https://doi.org/10.1007/s11771-006-0068-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-006-0068-7