Abstract

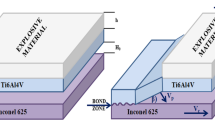

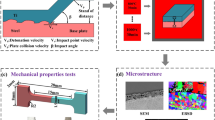

The present work pertains to the study of microstructure and mechanical properties of explosively cladded commercially pure titanium (cpTi) with austenitic stainless steel (SS 304L) subjected to varied process parameters, viz., loading ratios (mass of explosive or mass of flyer plate) and preset angles. The microstructural study reveals the transformation from straight to wavy interface while increasing loading ratios. Vickers hardness increases with loading ratios, and the maximum hardness is witnessed in the closer proximity of collision interface. Ram tensile and shear strength of explosive claddings are higher than that of parent plates. While the base plate fails in impact test, the flyer plate is deformed, indicating good impact strength. Increased mass of claddings, due to oxide formation, is witnessed in corrosion tests, which confirms the superiority of explosive claddings in corrosive environment. Triaxial weldability window, an analytical estimation for Ti−SS 304L explosive claddings, is developed and correlated.

Similar content being viewed by others

References

CROSSLAND B. Explosive welding of metals and its applications [M]. Oxford: Oxford University Press, 1982.

KAHRAMAN N, GULENC B, FINDIK F. Corrosion and mechanical-microstructural aspects of dissimilar joints of Ti–6Al–4V and Al plates [J]. International Journal of Impact Engineering, 2007, 34(8): 1423–1432.

RAO V N, REDDY M G, NAGARJUNA S. Structure and properties of explosive clad HSLA steel with titanium [J]. Transactions of Indian Institute of Metals, 2014, 67(1): 67–77.

SARAVANAN S, RAGHUKANDAN K. Diffusion kinetics in explosive cladding of dissimilar metals as described through the Miedema model [J]. Archives of Metallurgy and Materials, 2014, 59(4): 1615–1618.

MANIKANDAN P, HOKAMOTO K, DERIBAS A A, RAGHUKANDAN K, TOMOSHIGE R. Explosive welding of titanium/stainless steel by controlling energetic conditions [J]. Material Transactions, 2006, 47(8): 2049–2055.

ACARER M, GULENC B, FINDIK F. The influence of some factors on steel/steel bonding quality on their characteristics of explosive welding joints [J]. Journal of Materials Science, 2003, 39(21): 6457–6466.

SARAVANAN S, RAGHUKANDAN K, HOKAMOTO K. Improved microstructure and mechanical properties of dissimilar explosive cladding by means of interlayer technique [J]. Archives of Civil and Mechanical Engineering, 2016, 16: 563–568.

FINDIK F. Recent developments in explosive welding [J]. Materials and Design, 2011, 32(3): 1081–1093.

MOUSAVI S A A A, SARTANGI P F. Experimental investigation of explosive welding of cp-titanium/AISI 304 stainless steel [J]. Materials and Design, 2009, 30(3): 459–468.

SARAVANAN S, RAGHUKANDAN K. Thermal kinetics in explosive cladding of dissimilar metals [J]. Science and Technology of Welding and Joining, 2012, 17(2): 99–103.

ZAMANI E, LIAGHAT G H. Explosive welding of stainless steel-carbon steel coaxial pipes [J]. Journal of Materials Science, 2012, 47(2): 685–695.

TAMILCHELVAN P, RAGHUKANDAN K, SARAVANAN S. Kinetic energy dissipation in Ti-SS explosive cladding with multi loading ratios [J]. Iranian Journal of Science and Technology-Transactions of Mechanical Engineering, 2014, 38 (M1): 91–96.

MANIKANDAN P, HOKAMOTO K, FUJITA M, RAGHUKANDAN K, TOMOSHIGE R. Control of energetic conditions by employing interlayer of different thickness for explosive welding of titanium/304 stainless steel [J]. Journal of Materials Processing Technology, 2008, 195(1-3): 232–240.

BORCHERS C, LENZ M, DEUTGES M, KLEIN H, GÄRTNER M, HAMMERSCHMIDT M, KREYE H. Microstructure and mechanical properties of medium-carbon steel bonded on low-carbon steel by explosive welding [J]. Materials and Design, 2016, 89(8): 369–376.

ABE A. Numerical simulation of the plastic flow field near the bonding surface of explosive welding [J]. Journal of Materials Processing Technology, 1999, 85(S1-3): 162–165.

HONARPISHEH M, ASEMABADI M, SEDIGHI M. Investigation of annealing treatment on the interfacial properties of explosivewelded Al/Cu/Al multilayer [J]. Materials and Design, 2012, 37: 122–127.

KAÇAR R, ACARER M. Microstructure–property relationship in explosively welded duplex stainless steel–steel [J]. Materials Science and Engineering A, 2003, 363: 290–296.

WRONKA B. Testing of explosive welding and welded joints. The microstructure of explosive welded joints and their mechanical properties [J]. Journal of Material Science, 2010, 45(13): 3465–3469.

KAYA Y, KAHRAMAN N. An investigation into the explosive welding/cladding of Grade A ship steel/AISI 316L austenitic stainless steel [J]. Materials and Design, 2013, 52(24): 367–372.

KAHRAMAN N, GULENC B, FINDIK F. Joining of titanium/ stainless steel by explosive welding and effect on interface [J]. Journal of Materials Processing Technology, 2005, 169(2): 127–133.

ATHAR M M H, TOLAMINEJAD B. Weldability window and the effect of interface morphology on the properties of Al/Cu/Al laminated composites fabricated by explosive welding [J]. Materials and Design, 2015, 86: 516–525.

SARAVANAN S, RAGHUKANDAN K. Influence of interlayer in explosive cladding of dissimilar metals [J]. Materials and Manufacturing Processes, 2013, 28(5): 589–594.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Somasundaram, S., Krishnamurthy, R. & Kazuyuki, H. Effect of process parameters on microstructural and mechanical properties of Ti−SS 304L explosive cladding. J. Cent. South Univ. 24, 1245–1251 (2017). https://doi.org/10.1007/s11771-017-3528-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-017-3528-3