Abstract

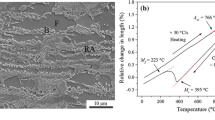

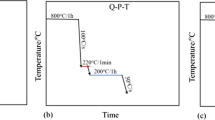

In the present work, paraffin phase change material is used as quenchant for the heat treatment of 42CrMo4 alloy and compared with water, air, and CuO doped paraffin. The samples were prepared based on ASTM E 8M-98 standard for tensile test and then heated up to 830 °C, kept for 4 h in an electric resistance furnace and then quenched in the mentioned media. Elastic modulus, yield strength, ultimate tensile strength, elongation, and modulus of toughness were determined according to the obtained stress-strain curves. Moreover, the hardness and microstructural evolution were investigated after the heat treatment at different media. The samples quenched in paraffin and CuO-doped paraffin are higher in ultimate tensile strength (1439 and 1306 MPa, respectively) than those quenched in water (1190 MPa) and air (1010 MPa). The highest hardness, with a value of HV 552, belonged to the sample quenched in CuO-doped paraffin. The microstructural studies revealed that the non-tempered steel had a ferrite/pearlite microstructure, while by quenching in water, paraffin and CuO-doped paraffin, ferrite/martensite microstructures were achieved. It is also observed that using the air as quenchant resulted in a three-phase bainite/martensite/ferrite microstructure.

摘要

采用石蜡相变材料作为42CrMo4 合金热处理的淬火介质, 并与用水、空气和CuO 掺杂石蜡作 淬火介质进行比较。根据ASTME8M−98 标准制备拉伸试样, 将试样在电阻炉中加热至830 °C, 然后 保温4 h, 再在上述介质中淬火。根据得到的应力−应变曲线确定弹性模量、屈服强度、极限抗拉强度、 伸长率和韧性模量。此外, 还研究了不同介质热处理后的硬度和显微组织演化。石蜡与CuO 掺杂石 蜡淬火样品的极限抗拉强度(分别为1439 和1306 MPa)高于在水(1190 MPa)和空气(1010 MPa)中淬火样 品的。CuO 掺杂石蜡淬火样品的硬度最高, 为HV552。显微组织研究表明, 非淬火钢具有铁素体/珠 光体组织, 而在水、石蜡和CuO 掺杂石蜡中淬火, 可获得铁素体/马氏体组织; 还观察到, 以空气为 淬火介质, 形成贝氏体/马氏体/铁素体三相组织。

Similar content being viewed by others

References

HUSSEIN A K, ABBAS L K, HASAN W N. Effect of quenching media variations on the mechanical behavior of martensitic stainless steel [J]. Al-Khwarizmi Eng J, 2019, 15: 1–12. DOI: 10.22153/kej.2019.11.002.

CANBAY C A, KARADUMAN O, ÜNLÜ N, BAIZ S A, ÖZKUL İ. Heat treatment and quenching media effects on the thermodynamical, thermoelastical and structural characteristics of a new Cu-based quaternary shape memory alloy [J]. Compos Part B, 2019, 174: 106940. DOI: 10.1016/j.compositesb.2019.106940.

RAYGAN S, RASSIZADEHGHANI J, ASKARI M. Comparison of microstructure and surface properties of AISI 1045 steel after quenching in hot alkaline salt bath and oil [J]. J Mater Eng Perform, 2009, 18: 168–173. DOI: 10.1007/s11665-008-9273-x.

de ANDRÉS GARCÍA C, CARUANA G, ALVAREZ L. Control of M23C6 carbides in 0.45C-13Cr martensitic stainless steel by means of three representative heat treatment parameters [J]. Mater Sci Eng A, 1998, 241: 211–215. DOI: 10.1016/S0921-5093(97)00491-7.

GRUM J, BOŽIČ S, ZUPANČIČ M. Influence of quenching process parameters on residual stresses in steel [J]. J Mater Process Technol, 2001, 114: 57–70. DOI: 10.1016/S0924-0136(01)00560-X.

BIRCH R, WANG S, TONG V S, BRITTON T B. The effect of cooling rate and grain size on hydride microstructure in zircaloy-4 [J]. J Nucl Mater, 2019, 513: 221–225. DOI: 10.1016/j.jnucmat.2018.11.011.

PEDERSEN L, ARNBERG L. The effect of solution heat treatment and quenching rates on mechanical properties and microstructures in AlSiMg foundry alloys [J]. Metall Mater Trans A, 2001, 32: 525–532. DOI: 10.1007/s11661-001-0069-y.

HAKAN GÜR C, PAN J. Handbook of thermal process modeling steels [M]. CRC Press, 2008. DOI: 10.1201/9781420003581.

LIŠČIĆ B, TENSI H M, LUTY W. Theory and technology of quenching [M]. Berlin, Heidelberg: Springer Berlin Heidelberg, 1992. DOI: 10.1007/978-3-662-01596-4.

HALL D D, MUDAWAR I. Experimental and numerical study of quenching complex-shaped metallic alloys with multiple, overlapping sprays [J]. Int J Heat Mass Transf, 1995, 38: 1201–1216. DOI: 10.1016/0017-9310(94)00244-P.

LISCIC B. State of the art in quenching[M]// Quenching and Carburizing. London: The Institute of Materials, 1993: 1–32.

FAKIR R, BARKA N, BROUSSEAU J. Mechanical properties analysis of 4340 steel specimen heat treated in oven and quenching in three different fluids [J]. Met Mater Int, 2018, 24: 981–991. DOI: 10.1007/s12540-018-0120-9.

MOGHANLOU F S, KHORRAMI A S, ESMAEILZADEH E, AMINFAR H. Experimental study on electrohydrodynamically induced heat transfer enhancement in a minichannel [J]. Exp Therm Fluid Sci, 2014, 59: 24–31. DOI: 10.1016/j.expthermflusci.2014.07.019.

WEBB R L, KIM N H. Principles enhanced heat transfer [M]. CRC Press, 2005.

EASTMAN J A, PHILLPOT S R, CHOI S U S, KEBLINSKI P. Thermal transport in nanofluids [J]. Annu Rev Mater Res, 2004, 34: 219–246. DOI: 10.1146/annurev.matsci.34.052803. 090621.

PIL J S, CHOI S U S. Effects of various parameters on nanofluid thermal conductivity [J]. J Heat Transfer, 2007, 129: 617. DOI: 10.1115/1.2712475.

TIWARI A K, GHOSH P, SARKAR J. Performance comparison of the plate heat exchanger using different nanofluids [J]. Exp Therm Fluid Sci, 2013, 49: 141–151. DOI: 10.1016/j.expthermflusci.2013.04.012.

CHOUGULE S S, SAHU S K. Comparative study of cooling performance of automobile radiator using Al2O3-water and carbon nanotube-water nanofluid [J]. J Nanotechnol Eng Med, 2014, 5: 010901. DOI: 10.1115/1.4026971.

MADHESH D, PARAMESHWARAN R, KALAISELVAM S. Experimental investigation on convective heat transfer and rheological characteristics of Cu-TiO2 hybrid nanofluids [J]. Exp Therm Fluid Sci, 2014, 52: 104–115. DOI: 10.1016/j.expthermflusci.2013.08.026.

PARK H S, SHIFERAW D, SEHGAL B R, KIM D K, MUHAMMED M. Film boiling heat transfer on a high temperature sphere in nanofluid [C]//2004 ASME Heat Transf Eng Summer Conf. Charlotte, NC, 2004.

KIM H, DEWITT G, MCKRELL T, BUONGIORNO J, HU L. On the quenching of steel and zircaloy spheres in water-based nanofluids with alumina, silica and diamond nanoparticles [J]. Int J Multiph Flow, 2009, 35: 427–438. DOI: 10.1016/j.ijmultiphaseflow.2009.02.004.

FARID M M. Solar energy storage with phase change [J]. J Sol Energy Res, 1986, 4: 11–29.

LANE G A. Solar heat storage phase-chang materials [M]// CRC Press, 2018. DOI: 10.1201/9781351076746.

MORCOS V H. Investigation of a latent heat thermal energy storage system [J]. Sol Wind Technol, 1990, 7: 197–202. DOI: 10.1016/0741-983X(90)90087-I.

LI J H, ZHANG G, WANG J Y. Investigation of a eutectic mixture of sodium acetate trihydrate and urea as latent heat storage [J]. Sol Energ, 1991, 47: 443–445. DOI: 10.1016/0038- 092X(91)90112-A.

HIMPEL M, HIEBLER S, SCHWEIGLER C, HELM M. Long-term test results from a latent heat storage developed for a solar heating and cooling system [C]// Proc Euro Sun 2010 Conf. Freiburg, Germany: International Solar Energy Society, 2010: 1–8. DOI: 10.18086/eurosun.2010.16.08.

MORRISON D J, ABDEL-KHALIK S I. Effects of phase-change energy storage on the performance of air-based and liquid-based solar heating systems [J]. Sol Energy, 1978, 20: 57–67. DOI: 10.1016/0038-092X(78)90141-X.

DAS S, DUTTA T K. Mathematical modeling and experimental studies on solar energy storage in a phase change material [J]. Sol Energy, 1993, 51: 305–312. DOI: 10.1016/0038-092X(93)90142-B.

TYAGI V V, BUDDHI D. PCM thermal storage in buildings: A state of art [J]. Renew Sustain Energy Rev, 2007, 11: 1146–1166. DOI: 10.1016/j.rser.2005.10.002.

SHARMA A, TYAGI V V, CHEN C R, BUDDHI D. Review on thermal energy storage with phase change materials and applications [J]. Renew Sustain Energy Rev, 2009, 13: 318–345. DOI: 10.1016/j.rser.2007.10.005.

ZALBA B, MARÍN J M, CABEZA L F, MEHLING H. Review on thermal energy storage with phase change: Materials, heat transfer analysis and applications [J]. Appl Therm Eng, 2003, 23: 251–283. DOI: 10.1016/S1359-4311(02)00192-8.

MA G, LIU S, XIE S, JING Y, ZHANG Q, SUN J, JIA Y. Binary eutectic mixtures of stearic acid-n-butyramide/ n-octanamide as phase change materials for low temperature solar heat storage [J]. Appl Therm Eng, 2017, 111: 1052–1059. DOI: 10.1016/j.applthermaleng.2016.10.004.

MENG Z N, ZHANG P. Experimental and numerical investigation of a tube-in-tank latent thermal energy storage unit using composite PCM [J]. Appl Energy, 2017, 190: 524–539. DOI: 10.1016/j.apenergy.2016.12.163.

WATANABE T, KIKUCHI H, KANZAWA A. Enhancement of charging and discharging rates in a latent heat storage system by use of PCM with different melting temperatures [J]. Heat Recover Syst CHP, 1993, 13: 57–66. DOI: 10.1016/0890-4332(93)90025-Q.

MEHLING H, HIEBLER S, ZIEGLER F. Latent heat storage using a PCM-graphite composite material [M]. Terrastock, 2000.

JEGADHEESWARAN S, POHEKAR S D, KOUSKSOU T. Conductivity particles dispersed organic and inorganic phase change materials for solar energy storage-An exergy based comparative evaluation [J]. Energy Procedia, 2012, 14: 643–648. DOI: 10.1016/j.egypro.2011.12.989.

SHUKLA A, BUDDHI D, SAWHNEY R L. Thermal cycling test of few selected inorganic and organic phase change materials [J]. Renew Energy, 2008, 33: 2606–2614. DOI: 10.1016/j.renene.2008.02.026.

SCIACOVELLI A, COLELLA F, VERDA V. Melting of PCM in a thermal energy storage unit: Numerical investigation and effect of nanoparticle enhancement [J]. Int J Energy Res, 2013, 37: 1610–1623. DOI: 10.1002/er.2974.

NEKAHI S, VAJDI M, MOGHANLOU F S, VAFERI K, MOTALLEBZADEH A, OZEN M, AYDEMIR U, SHA J, SHAHEDI ASL M. TiB2-SiC-based ceramics as alternative efficient micro heat exchangers [J]. Ceram Int, 2019, 45(15): 19060–19067. DOI: 10.1016/j.ceramint.2019.06.150.

CUI W, YUAN Y, SUN L, CAO X, YANG X. Experimental studies on the supercooling and melting/freezing characteristics of nano-copper/sodium acetate trihydrate composite phase change materials [J]. Renew Energy, 2016, 99: 1029–1037. DOI: 10.1016/j.renene.2016.08.001.

SUN C, FU P X, LIU H W, LIU H H, DU N Y. Effect of tempering temperature on the low temperature impact toughness of 42CrMo4-V steel [J]. Metals (Basel), 2018, 8(4): 232. DOI: 10.3390/met8040232.

ASTM E415-17. Standard test method for analysis of carbon and low-alloy steel by sparkatomic emission spectrometry [S]. 2017.

ASTM E 8M-98. Standard test methods for tension testing of metallic materials [S]. 1998.

ASTM E92-82. Standard test methods for vickers hardness of metallic materials [S]. 2003.

AHMAD E, MANZOOR T, ALI K L, AKHTER J I. Effect of microvoid formation on the tensile properties of dual-phase steel [J]. J Mater Eng Perform, 2000, 9: 306–310. DOI: 10.1361/105994900770345962.

SHAIKH K, INAMDAR S, QURESHI H, BIDRI U, ZAID S. To study the behaviour of materials AISI 1050, 1090, 4140 using conventional quenching and nano quenching [J]. Int J Eng Trends Technol, 2016, 38: 81–84. DOI: 10.14445/22315381/IJETT-V38P216.

CLAESSON E. Development of a heat treatment method to form a duplex microstructure of lower bainite and martensite in AISI 4140 steel [D]. Stockholm, Sweden: Department of Material Science and Engineering, Royal Institute of Technology, 2014.

CHUAIPHAN W, SRIJAROENPRAMONG L, PINPRADUB D. The effects of heat treatment on microstructure and mechanical properties of AISI 4140 for base cutter cane harvester [J]. Adv Mater Res, 2013, 774-776: 1059–1067. DOI: 10.4028/www.scientific.net/AMR.774-776.1059.

PORUKS P, YAKUBTSOV I, BOYD J D. Martensite-ferrite interface strength in a low-carbon bainitic steel [J]. Scr Mater, 2006, 54: 41–45. DOI: 10.1016/j.scriptamat.2005.09.012.

GURUMURTHY B M, SHARMA S S, GOWRI SHANKAR M C, WALIA R, AGARWAL T. Study on dual-phase structure of AISI4140 steel [J]. Indian J Sci Technol, 2016, 9: 1–6. DOI: 10.17485/ijst/2016/v9i33/93526.

SHAKERIFARD B, GALAN LOPEZ J, HISKER F, KESTENS L A I. Effect of banding on micro-mechanisms of damage initiation in bainitic/martensitic steels [J]. Mater Sci Eng A, 2018, 735: 324–335. DOI: 10.1016/j.msea.2018.08.049.

LEONG K Y, ABDUL RAHMAN M R, GURUNATHAN B A. Nano-enhanced phase change materials: A review of thermo-physical properties, applications and challenges [J]. J Energy Storage, 2019, 21: 18–31. DOI: 10.1016/j.est.2018.11.008.

KANG S S, BOLOURI A, KANG C G. The effect of heat treatment on the mechanical properties of a low carbon steel (0.1%) for offshore structural application [J]. Proc Inst Mech Eng Part L: J Mater Des Appl, 2012, 226: 242–251. DOI: 10.1177/1464420712438502.

KIM H, LIU Z, CONG W, ZHANG H C. Tensile fracture behavior and failure mechanism of additively-manufactured AISI 4140 low alloy steel by laser engineered net shaping [J]. Materials (Basel), 2017, 10: 1283. DOI: 10.3390/ma10111283.

SAEIDI N, EKRAMI A. Comparison of mechanical properties of martensite/ferrite and bainite/ferrite dual phase 4340 steels [J]. Mater Sci Eng A, 2009, 523: 125–129. DOI: 10.1016/j.msea.2009.06.057.

CAI X L, FENG J, OWEN W S. The dependence of some tensile and fatigue properties of a dual-phase steel on its microstructure [J]. Metall Trans A, 1985, 16: 1405–1415. DOI: 10.1007/BF02658673.

FENG J, FRANKENBACH T, WETTLAUFER M. Strengthening 42CrMo4 steel by isothermal transformation below martensite start temperature [J]. Mater Sci Eng A, 2017, 683: 110–115. DOI: 10.1016/j.msea.2016.12.013.

SALEMI A, ABDOLLAH-ZADEH A, MIRZAEI M, ASSADI H. A study on fracture properties of multiphase microstructures of a CrMo steel [J]. Mater Sci Eng A, 2008, 492: 45–48. DOI: 10.1016/j.msea.2008.02.043.

CALIK A. Effect of cooling rate on hardness and microstructure of AISI 1020, AISI 1040 and AISI 1060 Steels [J]. International Journal of the Physical Sciences, 2009, 4(9): 514–518.

de SILVA R A, de SOUZA L F G, MORALES E V, RIOS P R, de BOTT I S. Formation of microphases and constituents from remaining austenite decomposition in AISI X80 steel under different processing conditions [J]. Mater Res, 2015, 18: 908–917. DOI: 10.1590/1516-1439.315214.

SAKKAKI M, SADEGH MOGHANLOU F, VAJDI M, PISHGAR F, SHOKOUHIMEHR M, SHAHEDI ASL M. The effect of thermal contact resistance on the temperature distribution in a WC made cutting tool [J]. Ceram Int, 2019, 45(17): 22196–22202. DOI: 10.1016/j.ceramint.2019.07.241.

SADEGH MOGHANLOU F, VAJDI M, SHA J, MOTALLEBZADEH A, SHOKOUHIMEHR M, SHAHEDI ASL M. A numerical approach to the heat transfer in monolithic and SiC reinforced HfB2, ZrB2 and TiB2 ceramic cutting tools [J]. Ceram Int, 2019, 43(13): 15892–15897. DOI: 10.1016/j.ceramint.2019.05.095.

SADEGH MOGHANLOU F, VAJDI M, MOTALLEBZADEH A, SHA J, SHOKOUHIMEHR M, SHAHEDI ASL M. Numerical analyses of heat transfer and thermal stress in a ZrB2 gas turbine stator blade [J]. Ceram Int, 2019, 45(14): 17742–17750. DOI: 10.1016/j.ceramint.2019.05.344.

VAFERI K, NEKAHI S, VAJDI M, SADEGH MOGHANLOU F, SHOKOUHIMEHR M, MOTALLEBZADEH A, SHA J, SHAHEDI ASL M. Heat transfer, thermal stress and failure analyses in a TiB2 gas turbine stator blade [J]. Ceram Int, 2019, 45(15): 19331–19339. DOI: 10.1016/j.ceramint.2019.06.184.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sakkaki, M., Sadegh Moghanlou, F., Parvizi, S. et al. Phase change materials as quenching media for heat treatment of 42CrMo4 steels. J. Cent. South Univ. 27, 752–761 (2020). https://doi.org/10.1007/s11771-020-4328-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4328-8