Abstract

This paper provides an overview of the current approaches to predict damage and failure of composite laminates at the micro-(constituent), meso-(ply), and macro-(structural) levels, and their application to understand the underlying physical phenomena that govern the mechanical response of thin-ply composites. In this context, computational micro-mechanics is used in the analysis of ply thickness effects, with focus on the prediction of in-situ strengths. At the mesoscale, to account for ply thickness effects, theoretical results are presented related with the implementation of failure criteria that account for the in-situ strengths. Finally, at the structural level, analytical and computational fracture approaches are proposed to predict the strength of composite structures made of thin plies. While computational mechanics models at the lower (micro- and meso-) length-scales already show a sufficient level of maturity, the strength prediction of thin-ply composite structures subjected to complex loading scenarios is still a challenge. The former (micro- and meso-models) provide already interesting bases for in-silico material design and virtual testing procedures, with most of current and future research focused on reducing the computational cost of such strategies. In the latter (structural level), analytical Finite Fracture Mechanics models—when closed-form solutions can be used, or the phase field approach to brittle fracture seem to be the most promising techniques to predict structural failure of thin-ply composite structures.

Similar content being viewed by others

Notes

\(125\,\hbox {g/m}^2\) is typically regarded as the minimum dry ply areal weight of conventional low-grade CFRPs.

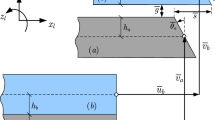

The distinction between thin- and thick-ply behaviour in Eqs. (1) and (4), respectively, separates the cases of stable crack propagation in the longitudinal direction (crack tunnelling) after through-thickness propagation (thin-ply case), and unstable through-thickness propagation of the transverse crack without stable crack tunnelling, as longitudinal propagation occurs immediately after but at a lower applied stress (thick-ply case) [33, 67, 178]. The theory shows that the transverse stress level at which unstable though-thickness crack propagation occurs is independent of the ply thickness—thick-ply case, Eq. (4). However, stable propagation parallel to the fibres occurs at higher stress levels as the ply thickness decreases—thin-ply case, Eq. (1). Hence, for a ply thickness at which the stress level needed for stable propagation in the longitudinal direction is higher than for unstable through-thickness propagation, increasing strength with decreasing ply thickness is observed (Fig. 7).

It is noted that, in the case of in-plane shear, Linear Elastic Fracture Mechanics alone is not able to accurately predict the in-situ strength, and the non-linear shear response typically observed in laminated composites must be included in the models [33].

The use of strain space is justified by the fact that, in this case, failure envelopes are invariant [175]; in other words, in strain space, the shapes of the failure envelopes are independent of the presence of other plies.

References

Abdalla MM, Setoodeh S, Gürdal Z (2007) Design of variable stiffness composite panels for maximum fundamental frequency using lamination parameters. Compos Struct 81:283–291

Abisset E, Daghia F, Ladevèze P (2011) On the validation of a damage mesomodel for laminated composites by means of open-hole tensile tests on quasi-isotropic laminates. Compos Part A Appl Sci 42:1515–1524

Aboudi J, Arnold SM, Bednarcyk BA (2013) Micromechanics of composite materials: a generalized multiscale analysis approach. Elsevier, Amsterdam

Achard V, Bouvet C, Castanié B, Chirol C (2014) Discrete ply modelling of open hole tensile tests. Compos Struct 113:369–381

Amacher R, Cugnoni J, Botsis J, Sorensen L, Smith W, Dransfeld C (2014) Thin ply composites: experimental characterization and modeling of size-effects. Compos Sci Technol 101:121–132

Areias P, Rabczuk T, Camanho PP (2013) Initially rigid cohesive laws and fracture based on edge rotations. Comput Mech 52:931–947

Arteiro A (2016) Structural mechanics of thin-ply laminated composites. Ph.D. thesis, Faculdade de Engenharia, Universidade do Porto, Porto

Arteiro A, Catalanotti G, Xavier J, Camanho PP (2013a) Notched response of non-crimp fabric thin-ply laminates. Compos Sci Technol 79:97–114

Arteiro A, Catalanotti G, Xavier J, Camanho PP (2013b) Notched response of non-crimp fabric thin-ply laminates: analysis methods. Compos Sci Technol 88:165–171

Arteiro A, Catalanotti G, Melro AR, Linde P, Camanho PP (2014a) Micro-mechanical analysis of the in situ effect in polymer composite laminates. Compos Struct 116:827–840

Arteiro A, Catalanotti G, Xavier J, Camanho PP (2014b) Large damage capability of non-crimp fabric thin-ply laminates. Compos Part A Appl Sci 63:110–122

Arteiro A, Catalanotti G, Melro AR, Linde P, Camanho PP (2015) Micro-mechanical analysis of the effect of ply thickness on the transverse compressive strength of polymer composites. Compos Part A Appl Sci 79:127–137

Arteiro A, Catalanotti G, Xavier J, Linde P, Camanho PP (2017) Effect of tow thickness on the structural response of aerospace-grade spread-tow fabrics. Compos Struct 179:208–223

Arteiro A, Catalanotti G, Xavier J, Linde P, Camanho PP (2018) A strategy to improve the structural performance of non-crimp fabric thin-ply laminates. Compos Struct 188:438–449

Aymerich F, Pani C, Priolo P (2007) Damage response of stitched cross-ply laminates under impact loadings. Eng Fract Mech 74:500–514

Bäcklund J, Aronsson CG (1986) Tensile fracture of laminates with holes. J Compos Mater 20:259–286

Bai X, Bessa MA, Melro AR, Camanho PP, Guo L, Liu WK (2015) High-fidelity micro-scale modeling of the thermo-visco-plastic behavior of carbon fiber polymer matrix composites. Compos Struct 134:132–141

Bažant ZP, Oh BH (1983) Crack band theory for fracture of concrete. Mater Struct 16(93):155–177

Belytschko T, Song JH (2010) Coarse-graining of multiscale crack propagation. Int J Numer Methods Eng 81:537–563

Benzeggagh M, Kenane M (1996) Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Compos Sci Technol 56:439–449

Berthelot JM (2003) Transverse cracking and delamination in cross-ply glass-fiber and carbon-fiber reinforced plastic laminates: static and fatigue loading. Appl Mech Rev 56(1):111–147

Bischoff M, Ramm E (1997) Shear deformable shell elements for large strains and rotations. Int J Numer Methods Eng 40:4427–4449

Boniface L, Smith PA, Bader MG (1997) Transverse ply cracking in cross-ply CFRP laminates—initiation or propagation controlled? J Compos Mater 31(11):1080–1112

Borden MJ, Verhoosel CV, Scott MA, Hughes TJR, Landis CM (2012) A phase-field description of dynamic brittle fracture. Comput Method Appl Mech 217–220:77–95

Bourdin B, Francfort GA, Marigo JJ (2008) The variational approach to fracture. J Elast 91(1–3):5–148

Bouvet C, Rivallant S, Barrau JJ (2012) Low velocity impact modeling in composite laminates capturing permanent indentation. Compos Sci Technol 72:1977–1988

Buryachenko VA, Pagano NJ, Kim RY, Spowart JE (2003) Quantitative description and numerical simulation of random microstructures of composites and their effective elastic moduli. Int J Solids Struct 40:47–72

Camanho PP, Arteiro A (2017) Analysis models for polymer composites across different length scales. In: Fifty years of progress and achievement of the science, development, and applications. Springer International Publishing, Cham, chap 9, pp 199–279

Camanho PP (1999) Application of numerical methods to the strength prediction of mechanically fastened joints in composite laminates. Ph.D. thesis, Centre for Composite Materials, Imperial College of Science, Technology and Medicine, London

Camanho PP, Catalanotti G (2011) On the relation between the mode I fracture toughness of a composite laminate and that of a \(0^\circ\) ply: analytical model and experimental validation. Eng Fract Mech 78:2535–2546

Camanho PP, Lambert M (2006) A design methodology for mechanically fastened joints in laminated composite materials. Compos Sci Technol 66:3004–3020

Camanho PP, Dávila CG, de Moura MF (2003) Numerical simulation of mixed-mode progressive delamination in composite materials. J Compos Mater 37(16):1415–1438

Camanho PP, Dávila CG, Pinho ST, Iannucci L, Robinson P (2006) Prediction of in situ strengths and matrix cracking in composites under transverse tension and in-plane shear. Compos Part A Appl Sci 37:165–176

Camanho PP, Maimí P, Dávila CG (2007) Prediction of size effects in notched laminates using continuum damage mechanics. Compos Sci Technol 67:2715–2727

Camanho PP, Arteiro A, Turon A, Costa J, Guillamet G (2012a) Structural integrity of thin-ply laminates. JEC Compos Mag 71:49–50

Camanho PP, Erçin GH, Catalanotti G, Mahdi S, Linde P (2012b) A finite fracture mechanics model for the prediction of the open-hole strength of composite laminates. Compos Part A Appl Sci 43:1219–1225

Camanho PP, Bessa MA, Catalanotti G, Vogler M, Rolfes R (2013) Modeling the inelastic deformation and fracture of polymer composites—Part II: smeared crack model. Mech Mater 59:36–49

Camanho PP, Arteiro A, Catalanotti G, Melro AR, Vogler M (2015a) Three-dimensional invariant-based failure criteria for transversely isotropic fibre-reinforced composites. In: Camanho PP, Hallett SR (eds) Numerical modelling of failure in advanced composite materials. Woodhead Publishing, Cambridge, pp 111–150

Camanho PP, Arteiro A, Melro AR, Catalanotti G, Vogler M (2015b) Three-dimensional invariant-based failure criteria for fibre-reinforced composites. Int J Solids Struct 55:92–107

Canal LP, González C, Molina-Aldareguía JM, Segurado J, Llorca J (2012a) Application of digital image correlation at the microscale in fiber-reinforced composites. Compos Part A Appl Sci 43:1630–1638

Canal LP, González C, Segurado J, Llorca J (2012b) Intraply fracture of fiber reinforced composites: microscopic mechanisms and modeling. Compos Sci Technol 72:1223–1232

Carollo V, Reinoso J, Paggi M (2017) A 3D finite strain model for intralayer and interlayer crack simulation coupling the phase field approach and cohesive zone model. Compos Struct 182:636–651

Carollo V, Reinoso J, Paggi M (2018) Modeling complex crack paths in ceramic laminates: a novel variational framework combining the phase field method of fracture and the cohesive zone model. J Eur Ceram Soc. https://doi.org/10.1016/j.jeurceramsoc.2018.01.035

Carrere N, Laurin F, Maire JF (2012) Micromechanical-based hybrid mesoscopic 3D approach for non-linear progressive failure analysis of composite structures. J Compos Mater 46(19–20):2389–2415

Catalanotti G (2016) On the generation of RVE-based models of composites reinforced with long fibres or spherical particles. Compos Struct 138:84–95

Catalanotti G, Camanho PP (2013) A semi-analytical method to predict net-tension failure of mechanically fastened joints in composite laminates. Compos Sci Technol 76:69–76

Catalanotti G, Camanho PP, Marques AT (2013) Three-dimensional failure criteria for fiber-reinforced laminates. Compos Struct 95:63–79

Catalanotti G, Arteiro A, Hayati M, Camanho PP (2014) Determination of the mode I crack resistance curve of polymer composites using the size-effect law. Engng Fract Mech 118:49–65

Chang FK, Chen MH (1987) The in situ ply shear strength distribution in graphite/epoxy laminated composites. J Compos Mater 21:708–733

Chang KY, Liu S, Chang FK (1991) Damage tolerance of laminated composites containing an open hole subjected to tensile loadings. J Compos Mater 25:274–301

Chen BY, Pinho ST, Carvalho NVD, Baiz PM, Tay TE (2014) A floating node method for the modelling of discontinuities in composites. Eng Fract Mech 127:104–134

Chen BY, Tay TE, Pinho ST, Tan VBC (2016) Modelling the tensile failure of composites with the floating node method. Comput Method Appl Mech 308:414–442

Clayton JD, Knap J (2015) Phase field modeling of directional fracture in anisotropic polycrystals. Comput Mater Sci 98:158–169

CMH-17-1G (2012) Composite Materials Handbook, vol 1 of 6: polymer matrix composites: guidelines for characterization of structural materials. SAE International

CMH-17-3G (2012) Composite materials handbook, vol 3 of 6: polymer matrix composites: materials usage, design and analysis. SAE International

Cornetti P, Pugno N, Carpinteri A, Taylor D (2006) Finite fracture mechanics: a coupled stress and energy failure criterion. Eng Fract Mech 73:2021–2033

Cousigné O, Moncayo D, Coutellier D, Camanho P, Naceur H, Hampel S (2013) Development of a new nonlinear numerical material model for woven composite materials accounting for permanent deformation and damage. Compos Struct 106:601–614

Cousigné O, Moncayo D, Coutellier D, Camanho P, Naceur H (2014) Numerical modeling of nonlinearity, plasticity and damage in CFRP-woven composites for crash simulations. Compos Struct 115:75–88

Cuntze RG (2006) Efficient 3D and 2D failure conditions for UD laminae and their application within the verification of the laminate design. Compos Sci Technol 66:1081–1096

Czél G, Wisnom MR (2013) Demonstration of pseudo-ductility in high performance glass/epoxy composites by hybridisation with thin-ply carbon prepreg. Compos Part A Appl Sci 52:23–30

Daniel IM, Ishai O (2008) Engineering mechanics of composite materials. Oxford University Press, Oxford

Dávila CG, Camanho PP (2003) Analysis of the effects of residual strains and defects on skin/stiffner debonding using decohesion elements. Tech. Rep. AIAA Paper 2003-1465, NASA Langley Research Center, Hampton, Virginia

Dávila CG, Rose CA, Iarve EV (2014) Modeling fracture and complex crack networks in laminated composites. In: Mantič V (ed) Mathematical Methods and Models in Composites, Computational and Experimental Methods in Structures, Aliabadi FMH, Series editor, vol 5, Imperial College Press, London, chap 8, pp 297–347

Dávila CG, Camanho PP, Rose CA (2005) Failure criteria for FRP laminates. J Compos Mater 39(4):323–345

Dávila CG, Camanho PP, Turon A (2008) Effective simulation of delamination in aeronautical structures using shells and cohesive elements. J Aircr 45(2):663–672

Diao H, Bismarck A, Robinson P, Wisnom MR (2014) Production of continuous intermingled CF/GF hybrid composite via fibre tow spreading technology. In: Proceedings of ECCM16, Seville, pp 1–8

Dvorak GJ, Laws N (1987) Analysis of progressive matrix cracking in composite laminates II. First ply failure. J Compos Mater 21:309–329

Erçin GH, Camanho PP, Xavier J, Catalanotti G, Mahdi S, Linde P (2013) Size effects on the tensile and compressive failure of notched composite laminates. Compos Struct 96:736–744

Eriksson I, Aronsson CG (1990) Strength of tensile loaded graphite epoxy laminates containing cracks, open and filled holes. J Compos Mater 24:456–482

Feder J (1980) Random sequential adsorption. J Theor Biol 87:237–254

Flaggs DL (1985) Prediction of tensile matrix failure in composite laminates. J Compos Mater 19:29–50

Flaggs DL, Kural MH (1982) Experimental determination of the in situ transverse lamina strength in graphite/epoxy laminates. J Compos Mater 16:103–116

Fuller J, Wisnom MR (2015a) Exploration of the potential for pseudo-ductility in thin ply CFRP angle-ply laminates via an analytical method. Compos Sci Technol 112:8–15

Fuller J, Wisnom MR (2015b) Pseudo-ductility and damage suppression in thin ply CFRP angle-ply laminates. Compos Part A Appl Sci 69:64–71

Furtado C, Arteiro A, Catalanotti G, Xavier J, Camanho PP (2016) Selective ply-level hybridisation for improved notched response of composite laminates. Compos Struct 145:1–14

Furtado C, Arteiro A, Bessa MA, Wardle BL, Camanho PP (2017) Prediction of size effects in open-hole laminates using only the Young’s modulus, the strength, and the \({\cal{R}}\)-curve of the \(0^\circ\) ply. Compos Part A Appl Sci 101:306–317

Gan KW, Wisnom MR, Hallett SR (2014) Effect of high through-thickness compressive stress on fibre direction tensile strength of carbon/epoxy composite laminates. Compos Sci Technol 90:1–8

García IG, Mantič V, Blázquez A, París F (2014) Transverse crack onset and growth in cross-ply \([0/90]_s\) laminates under tension. Application of a coupled stress and energy criterion. Int J Solids Struct 51:3844–3856

Garrett KW, Bailey JE (1977) Multiple transverse fracture in \(90^\circ\) cross-ply laminates of a glass fibre-reinforced polyester. J Mater Sci 12:157–168

Gay D, Hoa SV (2007) Composite materials: design and applications, 2nd edn. CRC Press, Taylor and Francis Group, Boca Raton

González C, Llorca J (2007) Mechanical behavior of unidirectional fiber-reinforced polymers under transverse compression: microscopic mechanisms and modeling. Compos Sci Technol 67:2795–2806

González EV, Maimí P, Sainz de Aja JR, Cruz P, Camanho PP (2014) Effects of interply hybridization on the damage resistance and tolerance of composite laminates. Compos Struct 108:319–331

Guillamet G, Turon A, Costa J, Renart J, Linde P, Mayugo JA (2014) Damage occurrence at edges of non-crimp-fabric thin-ply laminates under off-axis uniaxial loading. Compos Sci Technol 98:44–50

Guillamet G, Turon A, Costa J, Linde P (2016) A quick procedure to predict free-edge delamination in thin-ply laminates under tension. Eng Fract Mech 168:28–39

Gültekin O, Dal H, Holzapfel GA (2016) A phase-field approach to model fracture of arterial walls: theory and finite element analysis. Comput Method Appl Mech 312:542–566

Hahn HT, Tsai SW (1973) Nonlinear elastic shear behavior of unidirectional composite laminae. J Compos Mater 7(1):102–118

Hashin Z (1980) Failure criteria for unidirectional fibre composites. J Appl Mech 47:329–334

Herráez M, Mora D, Naya F, Lopes CS, González C, Llorca J (2015) Transverse cracking of cross-ply laminates: a computational micromechanics perspective. Compos Sci Technol 110:196–204

Hesch C, Weinberg K (2014) Thermodynamically consistent algorithms for a finite-deformation phase field approach to fracture. Int J Numer Methods Eng 99(12):906–924

Hine PJ, Duckett RA, Kaddour AS, Hinton MJ, Wells GM (2005) The effect of hydrostatic pressure on the mechanical properties of glass fibre/epoxy unidirectional composites. Compos Part A Appl Sci 36:279–289

Hinton MJ, Kaddour AS, Soden PD (2004a) A further assessment of the predictive capabilities of current failure theories for composite laminates: comparison with experimental evidence. Compos Sci Technol 64:549–558

Hinton MJ, Kaddour AS, Soden PD (2004b) Evaluation of failure prediction in composite laminates: background to ‘part C’ of the exercise. Compos Sci Technol 64:321–327

Hobbiebrunken T, Hojo M, Adachi T, De Jong C, Fiedler B (2006) Evaluation of interfacial strength in CF/epoxies using FEM and in-situ experiments. Compos Part A Appl Sci 37:2248–2256

Iarve EV, Gurvich MR, Mollenhauer DH, Rose CA, Dávila CG (2011) Mesh-independent matrix cracking and delamination modeling in laminated composites. Int J Numer Methods Eng 88:749–773

Jacques S, De Baere I, Van Paepegem W (2014) Application of periodic boundary conditions on multiple part finite element meshes for the meso-scale homogenization of textile fabric composites. Compos Sci Technol 92:41–54

Jalalvand M, Wisnom MR, Hosseini-Toudeshky H, Mohammadi B (2014) Experimental and numerical study of oblique transverse cracking in cross-ply laminates under tension. Compos Part A Appl Sci 67:140–148

Jiang WG, Hallett SR, Green BG, Wisnom MR (2007) A concise interface constitutive law for analysis of delamination and splitting in composite materials and its application to scaled notched tensile specimens. Int J Numer Methods Eng 69:1982–1995

Jodrey WS, Tory EM (1985) Computer simulation of close random packing of equal spheres. Phys Rev A 32(4):2347

Kawabe K (2008) New spreading technology for carbon fiber tow and its application to composite materials. Sen-i Gakkaishi 64(8):262–267 in Japanese

Kawabe K, Matsuo T, Maekawa Z (1998) New technology for opening various reinforcing fiber tows. J Soc Mat Sci Jpn 47(7):727–734 in Japanese

Kawabe K, Sasayama H, Kageyama K, Ogata N (2008) Effect of ply thickness on compressive properties in multidirectionally laminated composites. J Jpn Soc Compos Mater 34:173–181 in Japanese

Klinkel S, Wagner W (1997) A geometrical nonlinear brick element based on the EAS-method. Int J Numer Methods Eng 40:4529–4545

Koerber H, Camanho PP (2011) High strain rate characterisation of unidirectional carbonepoxy IM7-8552 in longitudinal compression. Compos Part A Appl Sci 42:462–470

Koerber H, Xavier J, Camanho PP (2010) High strain rate characterisation of unidirectional carbon-epoxy IM7-8552 in transverse compression and in-plane shear using digital image correlation. Mech Mater 42:1004–1019

Laurin F, Carrere N, Huchette C, Maire JF (2012) A multiscale hybrid approach for damage and final failure predictions of composite structures. J Compos Mater 47(20–21):2713–2747

Leguillon D (2002) Strength or toughness? A criterion for crack onset at a notch. Eur J Mech A Solid 21:61–72

Ling D, Yang Q, Cox B (2009) An augmented finite element method for modeling arbitrary discontinuities in composites. Int J Fract 156:53–73

Liu G, Li Q, Msekh MA, Zuo Z (2016) Abaqus implementation of monolithic and staggered schemes for quasi-static and dynamic fracture phase-field model. Comput Mater Sci 121:35–47

Lopes CS, Gürdal Z, Camanho PP (2008) Variable-stiffness composite panels: buckling and first-ply failure improvements over straight-fibre laminates. Comput Struct 86:897–907

Lopes CS, Sábada S, González C, Llorca J, Camanho PP (2016) Physically-sound simulation of low-velocity impact on fiber reinforced laminates. Int J Impact Eng 92:3–17

Maimí P, Camanho PP, Mayugo JA, Dávila CG (2007a) A continuum damage model for composite laminates: Part I—constitutive model. Mech Mater 39:897–908

Maimí P, Camanho PP, Mayugo JA, Dávila CG (2007b) A continuum damage model for composite laminates: Part II—computational implementation and validation. Mech Mater 39:909–919

Maimí P, González EV, Camanho PP (2014) Comment to the paper ’Analysis of progressive matrix cracking in composite laminates II. First ply failure’. J Compos Mater 48(9):1139–1141

Mantič V (2009) Interface crack onset at a circular cylindrical inclusion under a remote transverse tension. Application of a coupled stress and energy criterion. Int J Solids Struct 46(6):1287–1304

Mar JW, Lin KY (1977) Fracture mechanics correlation for tensile failure of filamentary composites with holes. J Aircraft 14:703–704

Martin E, Leguillon D, Carrère N (2012) A coupled strength and toughness criterion for the prediction of the open hole tensile strength of a composite plate. Int J Solids Struct 49:3915–3922

Mayugo JA, Camanho PP, Maimí P, Dávila CG (2010) Analytical modelling of transverse matrix cracking of \(\{\pm \theta /90^n\}^s\) composite laminates under multiaxial loading. Mech Adv Mater Struc 17:237–245

Melro AR, Camanho PP, Pinho ST (2008) Generation of random distribution of fibres in long-fibre reinforced composites. Compos Sci Technol 68:2092–2102

Melro AR, Camanho PP, Pinho ST (2012a) Influence of geometrical parameters on the elastic response of unidirectional composite materials. Compos Struct 94:3223–3231

Melro AR, Camanho PP, Pires FMA, Pinho ST (2012b) Numerical simulation of the non-linear deformation of 5-harness satin weaves. Comp Mater Sci 61:116–126

Melro AR, Camanho PP, Pires FMA, Pinho ST (2013a) Micromechanical analysis of polymer composites reinforced by unidirectional fibres: Part I—constitutive modelling. Int J Solids Struct 50:1897–1905

Melro AR, Camanho PP, Pires FMA, Pinho ST (2013b) Micromechanical analysis of polymer composites reinforced by unidirectional fibres: Part II—micromechanical analyses. Int J Solids Struct 50:1906–1915

Miehe C, Hofacker M, Welschinger F (2010a) A phase field model for rate-independent crack propagation: robust algorithmic implementation based on operator splits. Comput Method Appl M 199(45–48):2765–2778

Miehe C, Welschinger F, Hofacker M (2010b) Thermodynamically consistent phase-field models of fracture: variational principles and multi-field FE implementations. Int J Numer Methods Eng 83(10):1273–1311

Miehe C, Schänzel LM, Ulmer H (2015) Phase field modeling of fracture in multi-physics problems. Part I. Balance of crack surface and failure criteria for brittle crack propagation in thermo-elastic solids. Comput Method Appl Mech 294:449–485

Mozaffari N, Voyiadjis GZ (2015) Phase field based nonlocal anisotropic damage mechanics model. Phys D 308:11–25

Nash NH, Young TM, McGrail PT, Stanley WF (2015) Inclusion of a thermoplastic phase to improve impact and post-impact performances of carbon fibre reinforced thermosetting composites: a review. Mater Des 85:582–597

Nguyen TT, Yvonnet J, Bornert M, Chateau C, Sab K, Romani R, Le Roy R (2016) On the choice of parameters in the phase field method for simulating crack initiation with experimental validation. Int J Fract 197(2):213–226

Ogihara S, Takeda N, Kobayashi A (1997) Experimental characterization of microscopic failure process under quasi-static tension in interleaved and toughness-improved CFRP cross-ply laminates. Compos Sci Technol 57:267–275

Oh JH, Jin KK, Ha SK (2006) Interfacial strain distribution of a unidirectional composite with randomly distributed fibers under transverse loading. J Compos Mater 40(9):759–778

Okereke MI, Akpoyomare OI (2013) A virtual framework for prediction of full-field elastic response of unidirectional composites. Comput Mater Sci 70:82–99

Olsson R (2015) Analytical prediction of damage due to large mass impact on thin ply composites. Compos Part A Appl Sci 72:184–191

Paggi M, Reinoso J (2017) Revisiting the problem of a crack impinging on an interface: A modeling framework for the interaction between the phase field approach for brittle fracture and the interface cohesive zone model. Comput Method Appl Mech 321:145–172

Paggi M, Corrado M, Reinoso J (2004) Fracture of solar-grade anisotropic polycrystalline silicon: a combined phase fieldcohesive zone model approach. Comput Method Appl Mech 330:123–148

Parvizi A, Bailey JE (1978) On multiple transverse cracking in glass fibre epoxy cross-ply laminates. J Mater Sci 13:2131–2136

Parvizi A, Garrett KW, Bailey JE (1978) Constrained cracking in glass fibre-reinforced epoxy cross-ply laminates. J Mater Sci 13:195–201

Pinho ST, Iannucci L, Robinson P (2006) Physically-based failure models and criteria for laminated fibre-reinforced composites with emphasis on fibre kinking: Part I: development. Compos Part A Appl Sci 37:63–73

Pinho ST, Iannucci L, Robinson P (2012) Material and structural response of polymer-matrix fibre-reinforced composites. J Compos Mater 46(19–20):2313–2341

Puck A, Schürmann H (1998) Failure analysis of FRP laminates by means of physically based phenomenological models. Compos Sci Technol 58:1045–1067

Puck A, Schürmann H (2002) Failure analysis of FRP laminates by means of physically based phenomenological models. Compos Sci Technol 62:1633–1662

Pyrz R (1994) Quantitative description of the microstructure of composites. Part I: morphology of unidirectional composite systems. Compos Sci Technol 50(2):197–208

Reinoso J, Blázquez A (2016) Application and finite element implementation of 7-parameter shell element for geometrically nonlinear analysis of layered CFRP composites. Compos Struct 139:263–276

Reinoso J, Arteiro A, Paggi M, Camanho PP (2017a) Strength prediction of notched thin ply laminates using finite fracture mechanics and the phase field approach. Compos Sci Technol 150:205–216

Reinoso J, Catalanotti G, Blázquez A, Areias P, Camanho PP, París F (2017b) A consistent anisotropic damage model for laminated fiber-reinforced composites using the 3D-version of the Puck failure criterion. Int J Solids Struct 126–127:37–53

Reinoso J, Paggi M, Linder C (2017c) Phase field modeling of brittle fracture for enhanced assumed strain shells at large deformations: formulation and finite element implementation. Comput Mech 59:981–1001

Rolfes R, Ernst G, Vogler M, Hühne C (2008) Material and failure models for textile composites. In: Camanho PP, Dávila CG, Pinho ST, Remmers JJC (eds) Mechanical response of composites, computational methods in applied sciences, vol 10. Springer, Dordrecht, pp 27–56

Saito H, Morita M, Kawabe K, Kanesaki M, Takeuchi H, Tanaka M, Kimpara I (2011) Effect of ply-thickness on impact damage morphology in CFRP laminates. J Reinf Plast Compos 30:1097–1106

Saito H, Takeuchi H, Kimpara I (2012) Experimental evaluation of the damage growth restraining in \(90^\circ\) layer of thin-ply CFRP cross-ply laminates. Adv Compos Mater 21:57–66

Saito H, Takeuchi H, Kimpara I (2014) A study of crack suppression mechanism of thin-ply carbon-fiber-reinforced polymer laminate with mesoscopic numerical simulation. J Compos Mater 48(17):2085–2096

Sebaey TA, Costa J, Maimí P, Batista Y, Blanco N, Mayugo JA (2014) Measurement of the in situ transverse tensile strength of composite plies by means of the real time monitoring of microcracking. Compos Part B Eng 65:40–46

Sihn S, Kim RY, Kawabe K, Tsai SW (2007) Experimental studies of thin-ply laminated composites. Compos Sci Technol 67:996–1008

Simo JC, Armero F (1992) Geometrically non-linear enhanced strain mixed methods and the method of incompatible modes. Int J Numer Methods Eng 33:1413–1449

Soden PD, Kaddour AS, Hinton MJ (2004) Recommendations for designers and researchers resulting from the world-wide failure exercise. Compos Sci Technol 64:589–604

Song K, Li Y, Rose CA (2011) Continuum damage mechanics models for the analysis of progressive failure in open-hole tension laminates. Tech. Rep. NF1676L-12382, NASA Langley Research Center, Hampton, Virginia

Spencer AJM (1987) Kinematic constraints, constitutive equations and failure rules for anisotropic materials. In: Boehler JP (ed) Applications of Tensor Functions in Solid Mechanics, CISM Courses and Lectures—No. 292. Springer, Wien, pp 187–201

Strobl M, Seelig T (2016) On constitutive assumptions in phase field approaches to brittle fracture. Proc Struct Integr 2:3705–3712

Sun CT, Tao J (1998) Prediction of failure envelopes and stress/strain behaviour of composite laminates. Compos Sci Technol 58:1125–1136

Swolfs Y, Gorbatikh L, Romanov V, Orlova S, Lomov SV, Verpoest I (2013a) Stress concentrations in an impregnated fibre bundle with random fibre packing. Compos Sci Technol 74:113–120

Swolfs Y, Gorbatikh L, Verpoest I (2013b) Stress concentrations in hybrid unidirectional fibre-reinforced composites with random fibre packings. Compos Sci Technol 85:10–16

Swolfs Y, McMeeking RM, Verpoest I, Gorbatikh L (2015a) Matrix cracks around fibre breaks and their effect on stress redistribution and failure development in unidirectional composites. Compos Sci Technol 108:16–22

Swolfs Y, McMeeking RM, Verpoest I, Gorbatikh L (2015b) The effect of fibre dispersion on initial failure strain and cluster development in unidirectional carbon/glass hybrid composites. Compos Part A Appl Sci 69:279–287

Swolfs Y, Verpoest I, Gorbatikh L (2015c) Issues in strength models for unidirectional fibre-reinforced composites related to Weibull distributions, fibre packings and boundary effects. Compos Sci Technol 114:42–49

Swolfs Y, Verpoest I, Gorbatikh L (2016) Maximising the hybrid effect in unidirectional hybrid composites. Mater Des 93:39–45

Tanné E, Li T, Bourdin B, Marigo J, Maurini C (2018) Crack nucleation in variational phase-field models of brittle fracture. J Mech Phys Solids 110:80–99

Tao J, Sun CT (1998) Influence of ply orientation on delamination in composite laminates. J Compos Mater 32(21):1933–1947

Tavares RP, Melro AR, Bessa MA, Turon A, Liu WK, Camanho PP (2016) Mechanics of hybrid polymer composites: analytical and computational study. Comput Mech 57:405–421

Tavares RP, Otero F, Turon A, Camanho PP (2017) Effective simulation of the mechanics of longitudinal tensile failure of unidirectional polymer composites. Int J Fract 208:269–285

Teichtmeister S, Miehe C (2015) Phase-field modeling of fracture in anisotropic media. Proc Appl Math Mech 15:159–160

Totry E, González C, Llorca J (2008a) Failure locus of fiber-reinforced composites under transverse compression and out-of-plane shear. Compos Sci Technol 68:829–839

Totry E, González C, Llorca J (2008b) Prediction of the failure locus of C/PEEK composites under transverse compression and longitudinal shear through computational mechanics. Compos Sci Technol 68:3128–3136

Totry E, Molina-Aldareguía JM, González C, Llorca J (2010) Effect of fiber, matrix and interface properties on the in-plane shear deformation of carbon-fiber reinforced composites. Compos Sci Technol 70:970–980

Trias D (2005) Analysis and simulation of transverse random fracture of long fibre reinforced composites. Ph.D. thesis, Universitat de Girona, Escola Politècnica Superior, Girona

Trias D, Costa J, Mayugo JA, Hurtado JE (2006) Random models versus periodic models for fiber reinforced composites. Comput Mater Sci 38:316–324

Tsai SW (2008) Strength and Life of Composites. Composites Design Group, Department of Aeronautics and Astronautics, Stanford University

Tsai SW, Melo JDD (2014) An invariant-based theory of composites. Compos Sci Technol 100:237–243

Tsai SW, Melo JDD (2015) Composite Materials Design and Testing—Unlocking mystery with invariants. Composites Design Group, Department of Aeronautics and Astronautics, Stanford University, Stanford

Tsai SW, Melo JDD (2016) A unit circle failure criterion for carbon fiber reinforced polymer composites. Compos Sci Technol 123:71–78

van der Meer FP, Dávila CG (2013) Cohesive modeling of transverse cracking in laminates under in-plane loading with a single layer of elements per ply. Int J Solids Struct 50:3308–3318

Van der Meer FP, Sluys LJ (2009) A phantom node formulation with mixed mode cohesive law for splitting in laminates. Int J Fract 158:107–124

Van der Meer FP, Sluys LJ (2010) Mesh-independent modeling of both distributed and discrete matrix cracking in interaction with delamination in composites. Eng Fract Mech 77:719–735

Varandas LF, Arteiro A, Bessa MA, Melro AR, Catalanotti G (2017) The effect of through-thickness compressive stress on mode II interlaminar crack propagation: a computational micromechanics approach. Compos Struct 182:326–334

Varna J, Berglund LA, Ericson ML (1997) Transverse single-fibre test for interfacial debonding in composites: 2. Modelling. Compos Part A Appl Sci 28A:317–326

Vaughan TJ, McCarthy CT (2010) A combined experimental numerical approach for generating statistically equivalent fibre distributions for high strength laminated composite materials. Compos Sci Technol 70:291–297

Vaughan TJ, McCarthy CT (2011a) A micromechanical study on the effect of intra-ply properties on transverse shear fracture in fibre reinforced composites. Compos Part A Appl Sci 42:1217–1228

Vaughan TJ, McCarthy CT (2011b) Micromechanical modelling of the transverse damage behaviour in fibre reinforced composites. Compos Sci Technol 71:388–396

Verhoosel CV, de Borst R (2013) A phase-field model for cohesive fracture. Int J Numer Methods Eng 96:43–62

Vignollet J, May S, de Borst R, Verhoosel CV (2014) Phase-field models for brittle and cohesive fracture. Meccanica 49:2587–2601

Violeau D, Ladevèze P, Lubineau G (2009) Micromodel-based simulations for laminated composites. Compos Sci Technol 69:1364–1371

Vogler TJ, Kyriakides S (2001) On the initiation and growth of kink bands in fiber composites: Part I. Experiments. Int J Solids Struct 38:2639–2651

Vogler M, Rolfes R, Camanho PP (2013) Modeling the inelastic deformation and fracture of polymer composites—Part I: plasticity model. Mech Mater 59:50–64

Waddoups ME, Eisenmann JR, Kaminski BE (1971) Macroscopic fracture mechanics of advanced composite materials. J Compos Mater 5:446–454

Walker TH, Avery WB, Ilcewicz LB, Poe, Jr CC, Harris CE (1991) Tension fracture of laminates for transport fuselage. Part I: material screening. In: Soderquist JR, Neri LM, Bohon HL (eds) Proceedings of the 9th DoD/NASA/FAA conference on fibrous composites in structural design, Lake Tahoe, Nevada, vol II, pp 747–787

Whitney JM, Nuismer RJ (1974) Stress fracture criteria for laminated composites containing stress concentrations. J Compos Mater 8:253–265

Wisnom MR (2010) Modelling discrete failures in composites with interface elements. Compos Part A Appl Sci 41:795–805

Wongsto A, Li S (2005) Micromechanical FE analysis of UD fibre-reinforced composites with fibres distributed at random over the transverse cross-section. Compos Part A Appl Sci 36:1246–1266

Yang S, Tewari A, Gokhale AM (1997) Modeling of non-uniform spatial arrangement of fibers in a ceramic matrix composite. Acta Mater 45(7):3059–3069

Yokozeki T, Aoki Y, Ogasawara T (2008) Experimental characterization of strength and damage resistance properties of thin-ply carbon fiber/toughened epoxy laminates. Compos Struct 82:382–389

Zobeiry N, Forghani A, McGregor C, Vaziri R, Poursartip A (2008) Progressive damage modeling of composite materials under both tensile and compressive loading regimes. In: Camanho PP, Dávila CG, Pinho ST, Remmers JJC (eds) Mechanical response of composites, computational methods in applied sciences, vol 10. Springer, Dordrecht, pp 179–195

Acknowledgements

This work was funded by AIRBUS under project 2genComp—second generation Composites; the authors gratefully acknowledge the support provided by AIRBUS. The first author would also like to thank the financial support provided by FCT–Fundação para a Ciência e a Tecnologia through National Funds in the scope of project MITP-TB/PFM/0005/2013. The third author is grateful to the support of the research projects funded by the Spanish Ministry of Economy and Competitiveness/FEDER (Projects DPI2012-37187, MAT2015-71036-P and MAT2015-71309-P) and the Andalusian Government (Projects of Excellence No. P11-TEP-7093 and P12-TEP-1050), and to the financial support of the European Research Council (ERC), Grant No. 306622 through the ERC Starting Grant “Multi-field and multi-scale Computational Approach to Design and Durability of PhotoVoltaic Modules”—CA2PVM. The last author gratefully acknowledges the funding of Project NORTE-01-0145-FEDER-000022–SciTech–Science and Technology for Competitive and Sustainable Industries, co-financed by Programa Operacional Regional do Norte (NORTE2020), Fundo Europeu de Desenvolvimento Regional (FEDER).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Arteiro, A., Catalanotti, G., Reinoso, J. et al. Simulation of the Mechanical Response of Thin-Ply Composites: From Computational Micro-Mechanics to Structural Analysis. Arch Computat Methods Eng 26, 1445–1487 (2019). https://doi.org/10.1007/s11831-018-9291-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11831-018-9291-2