Abstract

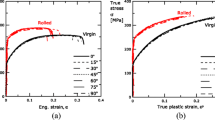

A custom mechanical stretching setup based on the Nakazima method was designed and built for testing sheet metals at elevated temperatures. Specimens from a fine-grained 5083 aluminum alloy sheet were deformed at various temperatures, spanning between those associated with warm forming (250°C) and hot forming (550°C). Circle grid analysis of the deformed specimens produced the forming limit curves at each of the covered temperatures, hence revealing the great influences of forming temperature on the material’s formability limits. Finally, all the curves were combined to construct a unique three-dimensional forming limit surface, which we present here as a more comprehensive map for describing material formability limits at wide-ranging temperatures.

Similar content being viewed by others

References

S.P. Keeler and W.A. Backhofen, Transactions of American Society of Metals, 56 (1963), pp. 25–48.

“Standard Test Method for Determining Forming Limit Curves,” ASTM E 2218-02 (West Conshohocken, PA: ASTM, 2002).

Z. Marciniak and Z. Kuczynski, Int. J. Mechanical Sciences, 9 (1967), pp. 609–620.

K. Nakazima, T, Kikuma, and K. Asuka, “Study on the Formability of Steel Sheet,” Yawata Technical Report No. 264 (1971), pp. 678–680.

R.A. Ayres, Novel Techniques in Metal Deformation Testing, ed. R.H. Wagoner (Warrendale, PA: TMS, 1983), pp. 47–64.

“Metallic Materials-Guidelines for the Determination of Forming Limit Diagrams,” ISO 12004.

A.K. Ghosh and S.S. Hecker, Metall. Trans., 5 (1974), pp. 2161–2164.

B. Taylor, Sheet Formability Testing, Metals Handbook, 9th ed., Vol. 8: Mechanical Testing (Materials Park, OH: American Society for Metals, 1985), pp. 547–570.

W.F. Hosford and J.L. Duncan, JOM, 51(11) (1999), pp. 39–44.

T. Foecke, S.W. Banovic, and R.J. Fields, JOM, 53(02) (2001), pp. 27–30.

E. Doege and K. Dröder, J. Mater. Proc. Technol., 115 (2001), pp. 14–19.

D. Li and A. Ghosh, J. Mater. Proc. Technol., 145 (2004), pp. 281–293.

S. Toros, F. Ozturk, and I. Kacar, J. Mater. Proc. Technol., 207 (2008), pp. 1–12.

M. Rashid, C. Kim, E. Ryntz, F. Saunders, R. Verma, and K. Sooho, “Quick Plastic Forming of Aluminum Alloy Sheet Metal,” U.S. patent 6 253 588 (2001).

P. Krajewski and J. Schroth, Mater. Sci. Forum, 551 552 (2007), pp. 3–12.

L. Hector, P. Krajewski, E. Taleff, and J. Carter, Key Engineering Materials, 433 (2010), pp. 197–210.

T. Naka, G. Torikai, R. Hino, and F. Yoshida, J. Mater. Proc. Technol., 113 (2001), pp. 648–653.

F.K. Chen and T.B. Huang, J. Mater. Proc. Technol., 142 (2003), pp. 643–647.

Y. Chino, H. Iwasaki, and M. Mabuchi, Mater. Sci. and Eng. A, 466 (2007), pp. 90–95.

E. Hsu, J. Carsley, and R. Verma, J. Mater. Eng. and Performance, 17(3) (2008), pp. 288–296.

F. Abu-Farha and B. Deeter, “Sheet Orientation Effects on the Formability Limits of the AZ31B Magnesium Alloy at SPF Conditions” (paper presented at the 6th International Manufacturing Science and Engineering Conference (MSEC 2011), Corvallis, OR, 13–17 June 2011), Paper No. MSEC2011-50177.

F. Abu-Farha and L. Hector, Jr., ASME J. Mfg. Sci. and Eng. (2011), DOI: 101115/14004850.

K.C. Chan and K.K. Chow, Int. J. Mech. Sci., 44 (2002), pp. 1467–1478.

D. Banabic, M. Vulcan, and K. Siegert, CIRP Annals-Manufacturing Technology, 54 (2005), pp. 205–208.

Y. Luo, C. Miller, G. Luckey, P. Friedman, and Y. Peng, J. Mater. Eng. and Performance, 16(3) (2007), pp. 274–283.

M. Kulas, P. Krajewski, J. Bradley, and E. Taleff, J. Mater. Eng. and Performance, 16(3) (2007), pp. 308–313.

M. Kulas, P. Krajewski, J. Bradley, and E. Taleff, Mater. Sci. Forum, 551-552 (2007), pp. 129–134.

F. Abu-Farha, N. Shuaib, M. Khraisheh, and K. Weinmann, CIRP Annals Manufacturing Technology, 57 (2008), pp. 275–278.

F. Abu-Farha, L. Hector, and P. Krajewski, “Forming Limit Curves for the AA5083 Alloy under Quick Plastic Forming Conditions” (Warrendale, PA: SAE, 2011), SAE Paper No. 2011-01-0235.

S.B. Leen, M.A. Kröhn, and T.H. Hyde, Materialwissenschaft und Werkstofftechnik, 39(4–5) (2008), pp. 327–331.

M.A. Kröhn, S.B. Leen, and T.H. Hyde, J. Mater. Design and Appl. (2007), pp. 251–264.

K. Siegert, S. Jäger, and M. Vulcan, CIRP Annals Manufacturing Technology, 52 (2003), pp. 241–244.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abu-Farha, F. The development of a forming limit surface for 5083 aluminum alloy sheet. JOM 63, 72–78 (2011). https://doi.org/10.1007/s11837-011-0194-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-011-0194-z