Abstract

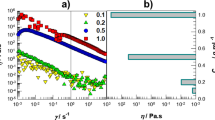

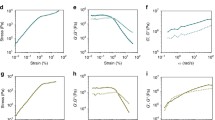

A stable gel of Au nanoparticles in polydimethylsiloxane (PDMS) nanocomposite is prepared by employing the curing agent of PDMS elastomer as a reducing agent for the formation of Au nanoparticles by an in-situ process. The viscoelastic nature of these gels is very sensitive to the Au nanoparticle loading and the synthetic temperature conditions. Even a very low Au content of 0.09 wt% is sufficient enough to bring in the transition from sponge state to gel state at room temperature. Higher synthetic temperature also forms sponge formation. Infrared and ultraviolet–visible spectroscopy measurements have provided insight into PDMS crosslinking and nanoparticle formation, respectively. The optimization of the gel properties can have direct influence on the processability of Au nanoparticle–PDMS nanocomposite gels, with interesting implications in electronic, optical and microfluidic devices.

Similar content being viewed by others

References

Takahashi H, Ishimuro Y and Watanabe H 2006 Nihon Reoroji Gakk 34 135

Mark J E 2004 Acc. Chem. Res. 37 946

Rajan G, Sur G, Mark J, Schaefer D and Beaucage G 2003 J. Polym. Sci. Pol. Phys. 41 1897

Qin D, Xia Y and Whitesides G M 2010 Nat. Protoc. 5 491

Lacour S P, Wagner S, Huang Z and Suo Z 2003 Appl. Phys. Lett. 82 2404

Adrega T and Lacour S P 2010 J. Micromech. Microeng. 20 055025

Buyl F D 2001 Int. J. Adhes. Adhes. 21 411

Rosen M R 2005 Delivery system handbook for personal care and cosmetic products: technology, applications and formulations (Norwich, NY: William Andrew Publishing) ISBN: 978-0-8155-1504-3

Kumar S K and Krishnamoorti R 2010 Annu. Rev. Chem. Biomol. Eng. 1 37

Niu X Z, Peng S L, Liu L Y, Wen W J and Sheng P 2007 Adv. Mater. 19 2682

Cong H and Pan T 2008 Adv. Funct. Mater. 18 1912

Kujawski M, Pearse J D and Smela E 2010 Carbon 48 2409

Zhang Y, Sheehan C J, Zhai J, Zou G, Luo H, Xiong J, Zhu Y T and Jia Q X 2010 Adv. Mater. 22 3027

Hong J, Lee J, Hong C K and Shim S E 2010 Curr. Appl. Phys. 10 359

Liu C H and Fan S S 2005 Appl. Phys. Lett. 86 123106

Mackay M E 2006 Science 311 1740

Kayatin M J and Davis V A 2009 Macromolecules 42 6624

Moreira L, Fulchiron R, Seytre G, Dubois P and Cassagnau P 2010 Macromolecules 43 1467

Anderson B J and Zukoski C F 2010 Langmuir 26 8709

Huang Y Y, Ahir S V and Terentjev E M 2006 Phys. Rev. B 73 125422

Bokobza L and Diop A L 2010 Express Polym. Lett. 4 355

Austin J R and Kontopoulou M 2006 Polym. Eng. Sci. 46 1491

Guimont A, Beyou E, Martin G, Sonntag P and Cassagnau P 2011 Macromolecules 44 3893

Marceau S, Dubois P, Fulchiron R and Cassagnau P 2011 Macromolecules 44 3893

Takahashi H, Ishimuro Y and Watanabe H 2007 Nihon Reoroji Gakk 35 191

Scott A, Gupta R and Kulkarni G U 2010 Macromol. Chem. Phys. 211 1640

Muñoz P, Patricia M A and Vargas M D 2001 J. Appl. Polym. Sci. 82 3460

Zhang Q, Xu J J, Liu Y and Chen H Y 2008 Lab. Chip 8 352

Zhang Q, Xu J J, Liua Y and Chen H Y 2008 Lab. Chip 8 352

Goyal A, Kumar A, Patra P K, Mahendra S, Tabatabaei S, Alvarez P. J J, John G and Ajayan P M 2009 Rapid Commun. 30 1116

Rau K R, Singh R and Goldberg E 2002 Mat. Res. Innovat. 5 162

Cai D and Neyer A 2010 Microfluid Nanofluid 9 855

Bhattacharya S, Srivastava A and Pal A 2006 Angew. Chem. Int. Ed. 45 2934

Thomas S and Stephen R 2009 Rubber nanocomposites: preparation, properties and applications (Wiley) ISBN: 978-0-470-82345-3

Walberer J A and McHugh A J 2001 J. Rheol. 45 187

Acknowledgements

We thank Professor CNR Rao for his encouragement. Support from the Department of Science and Technology, Government of India, is gratefully acknowledged. RG thanks ICMS, JNCASR for financial support. Thanks to K Veeresh and Swati (CPMU, JNCASR) for their assistance in gel preparation and B Vanitha for manuscript formatting.

ᅟ

Electronic Supplementary Material

Electronic Supplementary Material Supplementary Material pertaining to this article is available on the Bulletin of Materials Science website (www.ias.ac.in/matersci).

Author information

Authors and Affiliations

Corresponding author

Additional information

GIRIDHAR U KULKARNI is on lien from JNCASR, Bangalore 560064, India

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

GUPTA, R., NAGAMANASA, H.K., GANAPATHY, R. et al. Viscoelastic nature of Au nanoparticle–PDMS nanocomposite gels. Bull Mater Sci 38, 817–823 (2015). https://doi.org/10.1007/s12034-015-0957-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-015-0957-1