Abstract

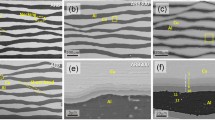

In the present research, laminated Al–Cu–Mg composite was processed by the accumulative roll bonding (ARB) method. Initially, aluminium, copper and magnesium strips were alternatively stacked together. Then these stacked strips were rolled at \(150^{\circ }\hbox {C}\) up to five ARB cycles. The microstructure of composites was studied by optical microscopy. Micro-hardness and tensile tests were conducted to evaluate mechanical properties of the processed composites. After the first cycle of ARB, it was observed that copper and magnesium layers were necked and fractured. With increasing ARB up to four cycles, laminated Al–Mg–Cu composite with homogeneous distribution of fragmented reinforcement in matrix was produced. It was observed that with increasing ARB up to four cycles the strength and micro-hardness of fabricated composites increased and elongation decreased at the same time. These differences in mechanical behaviour have been attributed to the microstructural aspects of the individual layers and the fragmentation processes.

Similar content being viewed by others

References

Li L, Nagai K and Yin F 2008 Sci. Technol. Adv. Mater. 9 023001

Scherm F, Völkl R, Van Smaalen S, Mondal S, Plamondon P, Espéranceb G L et al 2009 J. Mater. Sci. Technol. A 518 118

Shabani A, Toroghinejad M R and Shafyei A 2012 J. Mater. Sci. Technol. A 558 386

Huang X, Tsuji N, Hansen N and Minamino Y 2003 Mater. Sci. Eng. A 340 265

Lu C, Tieu K and Wexler D 2009 J. Mater. Process. Technol. 209 4830

Satio Y, Utsunomiya H, Tsuji N and Sakaki T 1999 Acta Mater. 47 579

Chang H, Zheng M Y, Xu C, Fan G D, Brokmeier H G and Wu K 2012 Mater. Sci. Eng. A 543 249

NasiriDehsorkhi R, Qods F and Tajally M 2011 J. Mater. Sci. Technol. A 530 63

Eizadjou M, Kazemi A, Talachi H, DaneshManesh, Shakur Shahabi H and Janghorban K 2008 Compos. Sci. Technol. 68 2003

Liu H S, Zhang B and Zhang G P 2011 J. Mater. Sci. Technol. 27 15

Zhang R and Acoff V L 2007 Mater. Sci. Eng. A 463 67

Min G, Lee J, Kang S and Kim H 2006 Mater. Lett. 60 3255

Danesh Manesh H and Karimi Taheri A 2003 J. Alloys Compd. 361 138

Yang D, Cizek P, Hodgson P and Wen C 2010 Scr. Mater. 62 321

Wu K, Chang H, Maawad E, Gan W M, Brokmeier H G and Zheng M Y 2010 Mater. Sci. Eng. A 527 3073

Alizadeh M and Talebian M 2012 J. Mater. Sci. Eng. A 558 331

Yu H, Tieu A K, Lu C, Liu X et al 2014 Sci. Rep. 4 Article no. 5017

Toroghinejad M R, Ashrafizadeh F and Jamaati R 2013 J. Mater. Sci. Eng. A 561 145

Chen M C, Hsieh H C and Wu W 2006 J. Alloys Compd. 416 169

Mozaffari A, DaneshManesh H and Janghorban K 2010 J. Alloys Compd. 489 103

Pasebani S and Toroghinejad M R 2010 Mater. Sci. Eng. A 527 491

Mei-yan Z, Yuan-yuan L and Wei-ping C 2008 Trans. Nonferrous Met. Soc. 18 309

Viswanathan V, Laha T, Balani K, Agarwal A and Seal S 2006 Mater. Sci. Eng. R 54 121

Khorshid M T, Jahromi S A J and Moshksar M M 2010 Mater. Des. 31 3880

Acknowledgements

The authors would like to thank the research board of the Sahand University of Technology for the provision of research facilities used in this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Motevalli, P.D., Eghbali, B. Microstructure and mechanical properties of laminated Al–Cu–Mg composite fabricated by accumulative roll bonding. Bull Mater Sci 40, 1481–1488 (2017). https://doi.org/10.1007/s12034-017-1504-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-017-1504-z