Abstract

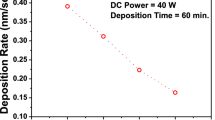

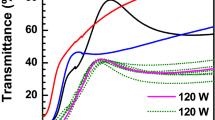

The quest for low power consumption devices with new functionalities has made the negative capacitance (NC) effect, the most captivating and studied phenomenon. The NC effect is observed in Cu–TiC thin film at a low-frequency range between 112.9 Hz and 2 kHz. The Cu–TiC thin film was deposited on Si (100) substrate by DC magnetron co-sputtering process and then annealed in a vacuum at different temperatures (100–600°C). The magnitude of NC increased from −0.016 to −27.5 µF after annealing. The NC behaviour is also observed in the forward biased region of the capacitance–voltage (C–V) characteristics. The current–voltage (I–V) characteristics reveal the decreasing static and dynamic resistance for higher annealed films. An improved electrical conductivity (27.70 × 103 to 384.62 × 103 S m−1) is evidenced with decreasing ideality factor (2.01–0.55) in the post-annealed films. The films were found to be polycrystalline from X-ray diffraction patterns with Cu and TiC phases. Raman studies have also confirmed the presence of Cu and TiC vibrational modes in all films. The intensity of C peaks detected at 1359 cm−1 (D peak) and at 1590 cm−1 (G peak) in the as-deposited film decreased after annealing. The annealing effect reduced the amount of unreacted carbon and contributed to form stoichiometric TiC from non-stoichiometric TiC.

Similar content being viewed by others

References

Groza J R and Gibeling J C 1993 Mater. Sci. Eng. A 171 115

Kim H G, Hanb S Z, Euhb K and Lim S H 2011 Mater. Sci. Eng. A 530 652

Barmouz M, Givi M K B and Seyfi J 2011 Mater. Charact. 62 108

Perez J F and Morris D G 1994 Scripta Metall. Mater. 31 231

Cho T, Bat D G and Woerner P F 1986 Surf. Coat. Technol. 29 239

Pancielejko M, Precht W and Czyzniewski A 2010 Vacuum 53 57

Zhuang J, Liu W B, Cao Z Y and Li Y Y 2010 Mats. Trans. 51 2311

Sabbaghiana M, Shamanian M, Akramifard H R and Esmailzadeh M 2014 Ceramics Intl. 40 12969

Rathod S, Modi O P, Prasad B K, Chrysanthou A, Vallauri D, Deshmukh V P et al 2009 Mater. Sci. Eng. A 502 91

Liang Y, Zhao Q, Zhang Z, Li X and Ren L 2014 J. Asian Ceram. Soc. 2 281

Soldan J and Musil J 2006 Vacuum 81 531

Chrysanthou A and Erbaccio G 1996 J. Mater. Sci. Lett. 15 774

Ogata K, Sakurai K, Fujita S and Matsushige K 2000 J. Cryst. Growth 214–215 312

Zhu D, Tang K, Song M and Tu M 2006 Trans. Nonferrous Met. Soc. China 16 459

Appleby D J R, Ponon N K, Kwa K S K, Zou B, Petrov P K, Wang T et al 2014 Nano Lett. 14 3864

Laurenti M, Verna A and Chiolerio A 2015 ACS Appl. Mater. Interfaces 7 24470

Chen N C, Wang P Y and Chen J F 1998 Appl. Phys Lett. 72 1081

Wang C C, Liu G Z, He M and Lu H B 2008 Appl. Phys. Lett. 92 052905

Bakueva L, Konstantatos G, Musikhin S, Ruda H E and Shik E 2004 Appl. Phys. Lett. 85 16

Ershov M, Liu H C, Li L, Buchanan M, Wasilewski Z R and Jonsche A K 1998 IEEE Trans. Electron. Devices 45 10

Wu X, Yang E S and Evans H L 1990 J. Appl. Phys. 68 2845

Jonscher A K and Robinson M N 1888 Solid-State Electron. 31 1277

Champness C H and Clark W R 1990 Appl. Phys. Lett. 56 1104

Ehrenfreund E, Lungenschmied C, Dennler G, Neugebauer H and Sariciftci N S 2007 Appl. Phys. Lett. 91 012

Jonscher A K 1986 J. Chem. Soc., Faraday Trans. 82 75

Das S C, Majumdar A, Katiyal S, Shripathi T and Hippler R 2014 Rev. Sci. Instrum. 85 025107

Cai K J, Zheng Y, Shena P and Chen S Y 2010 CrystEng Comm 16 5466

Shah J M, Li Y L, Gessmann T and Schubert E F 2003 J. Appl. Phys. 94 4

Gokarna A, Pavaskar N R, Sathaye S D, Ganesan V and Bhoraskar S V 2002 J. Appl. Phys. 92 4

Kalenga M P, Govindraju S, Airo M, Moloto M J, Sikhwivhilu L M and Moloto N 2015 J. Nanosci. Nanotech. 15 4480

Ferrari A C and Robertson J 1999 Phys. Rev. B 61 14095

Parravicini G B, Stella A, Ungureanu M C and Kofman R 2004 Appl. Phys. Lett. 85 302

Landau L D and Lifshitz E M 1960 Electrodynamics of continuous media (Oxford: Pergamon)

Hoffmann M, Fengler F P G and Herzig M 2019 Nature 565 464

Park H W, Roh J, Lee Y B and Hwang C S 2019 Adv. Mater. 31 1805266

Salahuddin S and Datta S 2008 Nano Lett. 8 405

Khan A K, Chatterjee K, Wang B, Drapcho S, You L, Serrao C et al 2015 Nat. Mater. 14 182

Íñiguez J, Zubko P, Luk’yanchuk I and Cano A 2019 Nat. Rev. Mater. 4 243

Lohse B H, Calka A and Wexler D 2005 J. Appl. Phys. 97 114912

Deng Y, Handoko A D, Du Y, Xi S and Yeo B S 2016 ACS Catal. 6 2473

Lespade P, Al-Jishi R and Dresselhaus M S 1982 Carbon 20 427

Lespade P, Marchard A, Couzi M and Cruege F 1984 Carbon 22 375

Nemanich R J and Solin S A 1979 Phys. Rev. B 20 392

Klein M V, Holy J A and Williams W S 1978 Phys. Rev. B 17 1546

Amer M, Barsoum M W, El-Raghy T, Weiss I, Leclair S and Liptak D 1998 J. Appl. Phys. 84 5817

Acknowledgements

We would like to thank Dr Sadhan Chandra Das and Dr Vasant Sathe, UGC-DAE CSR, Indore, India for their help in Raman experiments. We are also thankful to Professor Sukhen Das, Department of Physics, Jadavpur University, Kolkata, India, for providing the support of impedance analyser measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roy, A., Mukhopadhyay, A.K., Gupta, M. et al. Negative capacitance effect of Cu–TiC thin film deposited by DC magnetron plasma. Bull Mater Sci 43, 260 (2020). https://doi.org/10.1007/s12034-020-02234-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-020-02234-z