Abstract.

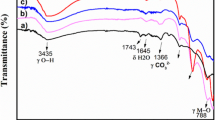

Porous chromium terephthalate MIL-101 (Cr-MIL-101) has been prepared by direct method under hydrothermal conditions and characterized using X-ray diffraction, N2 sorption, TGA and FT-IR. The nitrogen adsorption–desorption isotherm shows that the Cr-MIL-101 possesses BET specific surface area of 2563 m2/g. Catalytic performance of Cr-MIL-101 in the dehydration of 1,4-butanediol and 1-phenyl ethanol is assessed under vapour phase conditions in the temperature range of 513–533 K and time on stream (TOS) at 513 K. Cr-MIL-101 demonstrates superior catalytic activity with conversion of 95% of 1-phenyl ethanol. Moreover, high surface area and nanocages with coordinated unsaturated sites of Cr-MIL-101 have allowed us to attain higher dehydrated products selectivity than Cr-supported activated carbon (Cr/AC), amberlyst-15 and HZSM-5 catalysts.

Dehydration of 1-pheny lethanol and 1,4-butanediol has been carried out over Cr-MIL-101 catalyst in vapour phase in the temperature range of 498–533K at atmospheric pressure shows highest conversion and selectivity of styrene and tetrahydrofuran respectively, due to availability of co-ordinated unsatured sites and uniform distribution of pores of the catalyst.

Similar content being viewed by others

References

Long J R and Yaghi O M 2009 Chem. Soc. Rev. 38 1213

Wang H, Du Z and Duan Q 2002 Chem. Ind. Eng. Prog. 21 836

Ferry G, Draznieks C M, Serre C, Millange F, Dutour J, Surble S and Margiolaki I 2005 Science 309 2040

Boehm H P, Knozinger H, Anderson J R and BoudartM 1984 Catal. Sci. Technol. 4 40

Hunter S E, Ehrenberger C E and Savage P E 2006 J. Org. Chem. 71 6229

MabryM, PrichardWand Ziemecki S 1985 E.I. DuPont de Nemours and Company USP 4 550 185

MabryM, PrichardWand Ziemecki S 1986 E.I. DuPont de Nemours and Company USP 4 609 636

Herbert Muller 2002 Encyclopedia of Industrial Chemistry. (Wiley)

Li H, Yin H, Jiang T, Hu T, Wu J and Wada Y 2006 Catal. Commun. 7 778

Nazmul A K, Jin S H and Sung H J 2011 Bull. Korean Chem. Soc. 32 1327

Chang J S, Hong D Y, Vislovskiy V P and Park S E 2007 Catal. Survey Asia 11 59

Boelens M, Horton A D, Nisbet T M and Van Fort A B 2005 Process for Preparing Styrene. World Patent WO 054157 A1

Lamson J, Hall R H and Yats L D 1977 U.S. Patent 4049 736

Bos A and Koradia P B 2009 World Patent WO 074461 A1

Korchak E I 1967 U.S. Patent 344 2963

Sakthivel A, Badamali S K and Selvam P 2002 Catal. Lett. 80 1

Michorczyk P, Ogonowski J, Kustrowski P and Chmielarz L 2008 Appl. Catal. A 349 62

Nataliya V M, Konstantin A K, Sergey S A, Yurii A C, Maxim S M, Alexander G S, Vladimir P F and Kholdeeva A 2010 Inorg. Chem. 49 2920

Maksimchu N V, Timofeeva M N, Melgunov M S, Shmakov A N, Chesalov Y A, Dybtsev D N, Fedin V P and Kholdeeva O A 2008 J. Catal. 257 315

Li H, Yin H, Jiang T, Hu T, Wu J and Wada Y 2006 Catal. Commun. 7 778

Siva Kumar V, Nagaraja B M, Shashikala V, Padmasri A H, ShakuntalaMadhavendra S, David Raju B and Rama Rao K S 2004 J. Mol. Catal. A 223 313

Yang J, Zhao Q, Li J and Dong J 2010 Micropor. Mesopor. Mater. 130 174

Henschel A, Gedrich K, Kraehnert R and Kaskel S 2008 Chem. Commun. 4192

Zhang Z J, Huang S S, Xian S K, Xi H X and Li Z 2011 Energy Fuels 25 835

Qing L, Liqi N, Shudong Z, Mengna T, Yao S and He Y 2013 Scientific Rep. 3 2916

Hwang Y K, Hong D Y, Chang J, Jhung S H, Seo Y K, Kim J, Vimont A, Daturi M, C Serre and Ferey G 2008 Angew. Chem. Int. Ed. 47 4144

Inoue H, Sato S, Takahashi R, Izawa Y, Ohno H and Takahashi K 2009 Appl. Catal. A: General 352 66

Takahashi K 2009 Appl. Catal. A: General 352 66 Kobune M 2007 Catal. Commun. 8 807

Yamamoto N, Sato S, Takahashi R and Inui K 2005 Catal. Commun. 6 480

Yamamoto N, Sato S, Takahashi R and Inui K 2006 J. Mol. Catal. A 243 52

Sato S, Takahashi R, Sodesawa T and Yamamoto N 2004 Catal. Commun. 5 397

Acknowledgements

One of the authors MS thanks the Council of Scientific and Industrial Research (CSIR) New Delhi, India for the award of research fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

SURESH, M., DAVID RAJU, B., RAMA RAO, K.S. et al. Metal organic framework MIL-101(Cr) for dehydration reactions. J Chem Sci 126, 527–532 (2014). https://doi.org/10.1007/s12039-014-0590-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12039-014-0590-3