Abstract

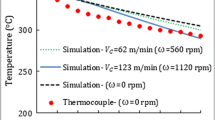

High corrosion resistance and mechanical properties of AISI 316 stainless steel make its wide application in the nuclear power station and structural components in chemical industries. On the contrary, low thermal conductivity and high strain rate create problems during the machining of AISI 316, resulting in high cutting force and tool wear. Hence, this study investigates the thermal and mechanical behavior of AISI 316 steel during turning using a carbide tool. It is carried out in two stages: Finite element modeling (FEM) and experimental work. In the first stage, FEM is simulated using DEFORM software to study cutting forces, tool temperature, and chip morphology at different cutting speeds and feed rates. The results show that cutting speed and feed rate significantly affect the cutting force, thrust force and chip morphology. The chip morphology characteristics such as the degree of segmentation and serration frequency are studied. In the second stage, experimental trials are performed using the same input parameters to validate the simulated results. Results show a 10% error between simulated and experimental findings.

Similar content being viewed by others

References

Saoubi R M, Outeiro J C, Changeux B, Lebrun J L and Mora A 1999 Residual stress analysis in orthogonal machining of standard and desulfurized AISI 316L steels. Journal of Material Processing Technology 96: 225–233

Varghese V, Ramesh M R and Chakradhar D 2018 Experimental investigation and optimization of machining parameters for sustainable machining. Mater. Manuf. Process 00: 1–11. https://doi.org/10.1080/10426914.2018.1476760

Ranganathan S, Senthilvelan T and Sriram G 2010 Evaluation of machining parameters of hot turning of stainless steel (Type 316) by applying ANN and RSM. Mater. Manuf. Process. 25: 1131–41. https://doi.org/10.1080/10426914.2010.489790

Altan N, Çiçek A, Gülesin M and Özbek O 2016 Effect of cutting conditions on wear performance of cryogenically treated tungsten carbide inserts in dry turning of stainless steel. Tribology Int. 94: 223–33. https://doi.org/10.1016/j.triboint.2015.08.024

Jerold B D and Kumar M P 2012 Machining of AISI 316 stainless steel under carbon-Di-Oxide cooling. Mater. Manuf. Process. 1059–1065. https://doi.org/10.1080/10426914.2011.654153

Manimaran G, Pradeep Kumar M and Venkatasamy R 2014 Influence of cryogenic cooling on surface grinding of stainless steel 316. Cryogenics 59: 76–83. https://doi.org/10.1016/j.cryogenics.2013.11.005

Cic A and Uygur I 2015 Machinability of AISI 316 austenitic stainless steel with cryogenically treated M35 high-speed steel twist drills. 134: 1–6. https://doi.org/10.1115/1.4007620

Katoh T, Ohmori S, Maeda T, Kakumitsu T and Okuda K 2015 Effect of High-pressure coolant supply on chip-breaking and tool wear in the machining of stainless steel; 657: 226–230. https://doi.org/10.4028/www.scientific.net/kem.656-657.226

Mia M and Dhar N R 2018 Effects of duplex jets high-pressure coolant on machining temperature and machinability of Ti-6Al-4V superalloy. J. Mater. Process. Technol. 252: 688–96. https://doi.org/10.1016/j.jmatprotec.2017.10.040

Naves V T G, Da Silva M B and Da Silva F J 2013 Evaluation of the effect of application of cutting fluid at high pressure on tool wear during turning operation of AISI 316 austenitic stainless steel. Wear 302: 1201–1208. https://doi.org/10.1016/j.wear.2013.03.016

Kaminski J and Alvelid B 2000 Temperature reduction in the cutting zone in water-jet assisted turning. Journal of Material Processing Technology 106: 68–73

Ozcelik B, Kuram E, Simsek B T, Ozcelik B, Kuram E and Simsek B T 2011 Comparison of dry and wet end milling of AISI 316 stainless steel. Mater. Manuf. Process. 6914. https://doi.org/10.1080/10426914.2010.515645

Amirabadi H 2018 High-pressure jet-assisted turning of AISI 304: Experimental and multi-objective optimization approach. In: Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering. 232: 734–750. https://doi.org/10.1177/0954408917738488

Davim J P, Maranhão C, Jackson M J, Cabral G and Grácio J 2008 FEM analysis in high-speed machining of aluminum alloy (Al7075-0) using polycrystalline diamond (PCD) and cemented carbide (K10) cutting tools. Int. J. Adv. Manuf.Technol. 39: 1093–100. https://doi.org/10.1007/s00170-007-1299-y

Maranhão C and Paulo Davim J 2010 Finite element modeling of machining of AISI 316 steel: Numerical simulation and experimental validation. Simul. Model. Pract. Theory; 18: 139–56. https://doi.org/10.1016/j.simpat.2009.10.001

Umbrello D, M’Saoubi R and Outeiro J C 2007 The influence of Johnson-Cook material constants on finite element simulation of machining of AISI 316L steel. Int. J. Mach. Tools Manuf. 47: 462–70. https://doi.org/10.1016/j.ijmachtools.2006.06.006

Nasr M N A, Ng E G and Elbestawi M A 2007 Modelling the effects of the tool-edge radius on residual stresses when orthogonal cutting AISI 316L. Int. J. Mach. Tools Manuf. 47: 401–11. https://doi.org/10.1016/j.ijmachtools.2006.03.004

Bonnet C, Valiorgue F, Rech J, Bergheau J M, Gilles P and Claudin C 2008 Development of a friction modeling method in dry cutting of AISI 316L austenitic stainless steels. International Journal of Material Forming 1: 1211–1214. https://doi.org/10.1007/s12289-008-0159-0

DEFORM 3D Version 11.0, User Manual. SFTC, Columbus, Ohio State. 2016

Müller C, Blümke R, Mu C and Blu R 2017 Influence of heat treatment and cutting speed on-chip segmentation of age hardenable aluminum alloy. Materials Science and Technology 17: 651–654.

Kishawy H A and Hosseini A 2019 Machining difficult-to-cut materials. Springer, Canada

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Parida, A.K., Rao, P.V. & Ghosh, S. Numerical analysis and experimental investigation in the machining of AISI 316 steel. Sādhanā 45, 1 (2020). https://doi.org/10.1007/s12046-019-1235-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-019-1235-5