Abstract

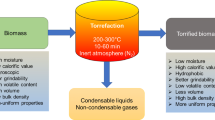

Torrefaction of biomass materials has received a tremendous attention over the years due to its ability to produce a high-grade solid biofuel with enhanced durability, excellent grindability, higher bulk density and calorific value, and greater energy density, as compared to the original untreated biomass material. It is a mild pyrolysis treatment technology under inert atmosphere which can improve the chemical and physical properties of raw biomass through the elimination of oxygen, reduction of moisture content, and change of chemical compositions. When raw biomass is mildly pyrolyzed in a default-oxygen or N2 atmosphere at moderate temperatures, the properties of raw biomass including low calorific value, hydrogen-carbon ratio, hygroscopicity, and grindability can be significantly enhanced. In the present review, the operating mechanism of different torrefaction processes including wet, dry, and ionic-liquid-assisted torrefaction is analyzed and discussed. More importantly, the reactor design for commercialization purpose, reaction kinetics and mechanism, economics, and sustainability of biomass torrefaction is discussed in detail. This review is extended to the torrefaction of agro-residue biomass since torrefied agro-residue-based pellets can be produced from agro-residues. The various technological applications of biomass torrefaction are also reviewed and the prospects in ensuring the continuous production of high-grade fuels are summarized.

Similar content being viewed by others

References

Onsree T, Tippayawong N, Williams T, McCullough K, Barrow E, Pogaku R, Lauterbach J (2019) Torrefaction of pelletized corn residues with wet flue gas. Bioresour Technol 285:1213302

Li SX, Chen CZ, Li MF, Xiao X (2018) Torrefaction of corncob to produce charcoal under nitrogen and carbon dioxide atmospheres. Bioresour Technol 249:348–353

Manouchehrinejad M, Mani S (2018) Torrefaction after pelletization (TAP): analysis of torrefied pellet quality and co-products. Biomass Bioenergy 118:93–104

Isemin R, Mikhalev A, Klimov D, Grammelis P, Margaritis N, Kourkoumpas DX, Zaichenko V (2017) Torrefaction and combustion of pellets made of a mixture of coal sludge and straw. Fuel 210:859–865

Lasek JA, Kopczyński M, Janusz M, Iluk A, Zuwała J (2017) Combustion properties of torrefied biomass obtained from flue gas-enhanced reactor. Energy 119:362–368

Sarvaramini A, Gravel O, Larachi F (2013) Torrefaction of ionic-liquid impregnated lignocellulosic biomass and its comparison to dry torrefaction. Fuel 103:814–826

Yek PNY, Liew RK, Osman MS, Lee CL, Chuah JH, Park YK, Lam SS (2019) Microwave steam activation, an innovative pyrolysis approach to convert waste palm shell into highly microporous activated carbon. J Environ Manag 236:245–253

Tanpichai S, Witayakran S, Boonmahitthisud A (2019) Study on structural and thermal properties of cellulose microfibers isolated from pineapple leaves using steam explosion. J Environ Chem Eng 7:1–7

Casazza AA, Spennati E, Converti A, Busca G (2020) Production of carbon-based biofuels by pyrolysis of exhausted Arthrospira platensis biomass after protein or lipid recovery. Fuel Process Technol 201:106336

Priya AS, Sunaja Devi KR (2020) Designing biomass rice husk silica as an efficient catalyst for the synthesis of biofuel additive n-Butyl levulinate. Bioenergy Res. https://doi.org/10.1007/s12155-020-10128-5

Van der Stelt MJC, Gerhauser H, Kiel JHA, Ptasinski KJ (2011) Biomass upgrading by torrefaction for the production of biofuels: a review. Biomass Bioenergy 35:3748–3762

Pérez-Rangel M, Barboza-Corona JE, Buitrón-Corona JE, Valdez-Vazquez I (2020) Essential nutrients for improving the direct processing of raw lignocellulosic substrates through the dark fermentation process. Bioenergy Res 13:349–357

Azevedo SG, Sequeira T, Santos M, Mendes L (2019) Biomass-related sustainability: a review of the literature and interpretive structural modeling. Energy 171:1107–1125

Seco A, Espuelas S, Marcelino S, Echeverría AM, Prieto E (2020) Characterization of biomass briquettes from spent coffee grounds and xanthan gum using low pressure and temperature. Bioenergy Res 13:369–377

Alcantara GU, Nogueira LC, Stringaci LA, Moya SM, Costa GH (2020) Brazilian “flex mills”: ethanol from sugarcane molasses and corn mash. Bioenergy Res 13:229–236

Sorn V, Chang KL, Phitsuwan P, Ratanakhanokchai K, Dong CD (2019) Effect of microwave-assisted ionic liquid/acidic ionic liquid pretreatment on the morphology, structure, and enhanced delignification of rice straw. Bioresour Technol 293:121929

Olugbade TO, Ojo OT (2020) Binderless briquetting technology for lignite briquettes: a review. Energy Ecol Environ. https://doi.org/10.1007/s40974-020-00165-3

Borén E, Pommer L, Nordin A, Larsson SH (2020) Off-gassing from pilot-scale torrefied pine chips: impact of torrefaction severity, cooling technology, and storage times. Fuel Process Technol 202:106380

Raitila J, Tsupari E (2020) Feasibility of solar-enhanced drying of woody biomass. Bioenergy Res 13:210–221

Kostas ET, White DA, Cook DJ (2020) Bioethanol production from UK seaweeds: investigating variable pre-treatment and enzyme hydrolysis parameters. Bioenergy Res 13:271–285

Manatura K (2020) Inert torrefaction of sugarcane bagasse to improve its fuel properties. Case Stud Therm Eng 19:100623

Bridgeman TG, Jones JM, Williams A, Waldron DJ (2010) An investigation of the grindability of two torrefied energy crops. Fuel 89:3911–3918

Phanphanich M, Mani S (2011) Impact of torrefaction on the grindability and fuel characteristics of forest biomass. Bioresour Technol 102:1246–1253

Mamvura TA, Danha G (2020) Biomass torrefaction as an emerging technology to aid in energy production. Heliyon 6:e03531

Medic D, Darr M, Shah A, Potter B, Zimmerman J (2012) Effects of torrefaction process parameters on biomass feedstock upgrading. Fuel 91:147–154

Melkior T, Jacob S, Gerbaud G, Hediger S, Pape LL, Bonnefois L, Bardet M (2012) NMR analysis of the transformation of wood constituents by torrefaction. Fuel 92:271–280

Hakkou M, Petrissans M, Gerardin P, Zoulalian A (2006) Investigations of the reasons for fungal durability of heat-treated beech wood. Polym Degrad Stab 91:393–397

Windeisen E, Strobel C, Wegener G (2007) Chemical changes during the production of thermo-treated beech wood. Wood Sci Technol 41:523–536

He Q, Ding L, Gong Y, Li W, Wei J, Yu G (2019) Effect of torrefaction on pinewood pyrolysis kinetics and thermal behavior using thermogravimetric analysis. Bioresour Technol 280:104–111

Zeng K, Yang Q, Zhang Y, Mei Y, Wang X, Yang H, Shao J, Li J, Chen H (2018) Influence of torrefaction with Mg-based additives on the pyrolysis of cotton stalk. Bioresour Technol 261:62–69

Yue Y, Singh H, Singh B, Mani S (2017) Torrefaction of sorghum biomass to improve fuel properties. Bioresour Technol 232:372–379

Kruczek H, Wnukowski M, Niedzwiecki Ł, Guziałowska-Tic J (2019) Torrefaction as a valorization method used prior to the gasification of sewage sludge. Energies 12:175

Rasche L, Sos Del Diego SR (2020) Pros and cons of sugarcane straw recovery in São Paulo. Bioenergy Res 13:147–156

Froese AG, Nguyen T, Ayele BT, Sparling R (2020) Digestibility of wheat and cattail biomass using a co-culture of thermophilic anaerobes for consolidated bioprocessing. Bioenergy Res 13:325–333

Chang SH (2020) Rice husk and its pretreatments for bio-oil production via fast pyrolysis: a review. Bioenergy Res 13:23–42

Grycova B, Pryszcz A, Krzack S, Lestinsky P (2020) Torrefaction of biomass pellets using the thermogravimetric analyser. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-020-00621-4

Pathomrotsakun J, Nakason K, Kraithong W, Khemthong P, Panyapinyopol B, Pavasat P (2020) Fuel properties of biochar from torrefaction of ground coffee residue: effect of process temperature, time, and sweeping gas. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-020-00632-1

Hossain N (2020) Characterization of novel moss biomass, Bryum dichotomum Hedw as solid fuel feedstock. Bioenergy Res 13:50–60

Szufa SS, Wielgosinski G, Piersa P, Czerwinska J, Dzikuc M, Adrian L, Lewandowska W, Marczak M (2020) Torrefaction of straw from oats and maize for use as a fuel and additive to organic fertilizers—TGA analysis, kinetics as products for agricultural purposes. Energies 13:2064

Szufa S, Dziku M, Adrian Ł, Piersa P, Romanowska-Duda Z, Marczak M, Błaszczuk A, Piwowar A, Lewandowska W (2020) Torrefaction of oat straw to use as solid biofuel, an additive to organic fertilizers for agriculture purposes and activated carbon—TGA analysis, kinetics. E3S Web Conf. 154:02004

Junga R, Pospolita J, Niemiec P (2020) Combustion and grindability characteristics of palm kernel shells torrefied in a pilot-scale installation. Renew Energy 147:1239–1250

Thilakaratne R, Brown T, Li Y, Hu G (2014) Mild catalytic pyrolysis of biomass for production of transportation fuels: a techno-economic analysis. Green hem 16:627–636

Zhang H, Luo M, Xiao R, Shao S, Jin B, Xiao G, Zhao M, Liang J (2014) Catalytic conversion of biomass pyrolysis-derived compounds with chemical liquid deposition (CLD) modified ZSM-5. Bioresour Technol 155:57–62

Thilakaratne R, Mark R, Wright M, Brown RC (2014) A techno-economic analysis of microalgae remnant catalytic pyrolysis and upgrading to fuels. Fuel 128:104–112

Lehto J, Oasmaa A, Solantausta Y, Kyto M, Chiaramonti D (2014) Review of fuel oil quality and combustion of fast pyrolysis bio-oils from lignocellulosic biomass. Appl Energy 116:178–190

Ren S, Lei H, Wang L, Bu Q, Chen S, Wu J (2013) Thermal behavior and kinetic study for woody biomass torrefaction and torrefied biomass pyrolysis by TGA. Biosyst Eng 116:420–426

Lanteigne JR, Laviolette JP, Chaouki J (2013) Biomass pre-treatments for biorefinery applications: pyrolysis. Pretreatment techniques for biofuels and biorefineries. Springer, Berlin Heidelberg, pp 229–260

Davies A, Soheilian R, Zhuo C, Levendis Y (2014) Pyrolytic conversion of biomass residues to gaseous fuels for electricity generation. J Energy Resour Technol 136:021101

Mu W, Ben H, Ragauskas A, Deng Y (2013) Pyrolysis components and upgrading—technology review. Bioenergy Res 6:1183–1204

Abuelnuor AAA, Wahid MA, Hosseini SE, Saat A, Saqr KM, Sait HH, Osman M (2014) Characteristics of biomass in flameless combustion: a review. Renew Sust Energ Rev 33:363–370

Wang C, Hu Y, Chen Q, Lv C, Jia S (2013) Bio-oil upgrading by reactive distillation using p-toluene sulfonic acid catalyst loaded on biomass activated carbon. Biomass Bioenergy 56:405–411

Wang C, Peng J, Li H, Bi XT, Legros R, Sokhansank S (2013) Oxidative torrefaction of biomass residues and densification of torrefied sawdust to pellets. Bioresour Technol 127:318–325

Kambo HS, Dutta A (2015) A comparative review of biochar and hydrochar in terms of production, physico-chemical properties and applications. Renew Sust Energ Rev 45:359–378

Tiffany DG, Lee WF, Morey V, Kaliyan N (2013) Economic analysis of biomass torrefaction plants integrated with corn ethanol plants and coal-fired power plants. Adv Energy Res 1:127–146

Brown D, Rowe A, Wild P (2013) A techno-economic analysis of using mobile distributed pyrolysis facilities to deliver a forest residue resource. Bioresour Technol 150:367–376

Kaliyan N, Morey V, Tiffany DG, Lee WF (2014) Life cycle assessment of a corn stover torrefaction plant integrated with a corn ethanol plant and a coal fired power plant. Biomass Bioenergy 63:92–100

Svanberg M, Halldórsson A (2013) Supply chain configuration for biomass-to-energy: the case of torrefaction. Int J Energy Sect Manag 7:65–83

Kuo PC, Wu WEI, Chen WH (2014) Gasification performances of raw and torrefied biomass in a downdraft fixed bed gasifier using thermodynamic analysis. Fuel 117:1231–1241

Liu Z, Quek A, Balasubramanian R (2014) Preparation and characterization of fuel pellets from woody biomass, agro-residues and their corresponding hydrochars. Appl Energy 113:1315–1322

Nilsson S, Gomez-Barea A, Fuentes-Cano D, Campoy M (2014) Gasification kinetics of char from olive tree pruning in fluidized bed. Fuel 125:192–199

Rahim AH, Man Z, Sarwono A, Muhammad N, Khan AS, Hamzah WSWH, Yunus NM, Elsheikh YA (2019) Probe sonication assisted ionic liquid treatment for rapid dissolution of lignocellulosic biomass. Cellulose. 27:2135–2148. https://doi.org/10.1007/s10570-019-02914-y

Cheng Q, Via B, Wang J, Zondlo J (2014) Primary study of woody biomass and coal for energy production investigated by TGA-FTIR analysis. BioResources 9:2899–2906

Sheikh MI, Kim CH, Park HJ, Kim SH, Kim GC, Lee JY, Sim SW, Kim JW (2013) Effect of torrefaction for the pretreatment of rice straw for ethanol production. J Sci Food Agric 93:3198–3204

Kinoshita T, Ohki T, Yamagata Y (2010) Woody biomass supply potential for thermal power plants in Japan. Appl Energy 87:2923–2927

Vargas-Moreno JM, Callejon-Ferre AJ, Perez-Alonso J, Velazquez-Marti B (2012) A review of the mathematical models for predicting the heating value of biomass materials. Renew Sust Energ Rev 16:3065–3083

Panwar NL, Kothari R, Tyagi VV (2012) Thermo chemical conversion of biomass—eco-friendly energy routes. Renew Sust Energ Rev 16:1801–1816

Timmons D, Mejía CV (2010) Biomass energy from wood chips: diesel fuel dependence? Biomass Bioenergy 34:1419–1425

Ruiz JA, Juarez MC, Morales MP, Munoz P, Mendivil MA (2013) Biomass gasification for electricity generation: review of current technology barriers. Renew Sust Energ Rev 18:174–183

Cavalli R, Grigolato S, Sgarbossa A, Francescato V, Negrin M (2011) Woodchips quality: the new UNI standards and their application. Sherwood—For Alberi Oggi 179:37–41

Hwang JS, Oh JH, Kim JS, Cha DS (2009) Analysis on the production costs and energy balance of heating wood-chip by yarding machines. J Korean For Soc 98:799–805

Leslie AD, Mencuccini M, Perks M (2012) The potential for Eucalyptus as a wood fuel in the UK. Appl Energy 89:176–182

Sacchelli S, Fagarazzi C, Bernetti I (2012) Economic evaluation of forest biomass production in central Italy: a scenario assessment based on spatial analysis tool, Biomass Bioenergy

Pirraglia A, Gonzalez R, Saloni D, Denig J (2013) Technical and economic assessment for the production of torrefied ligno-cellulosic biomass pellets in the US. Energy Convers Manag 66:153–164

Taba LE, Irfan MF, Daud WAMW (2012) The effect of temperature on various parameters in coal, biomass and CO-gasification: a review. Renew Sust Energ Rev 16:5584–5596

Puig-Arnavat M, Bruno JC (2010) Alberto Coronas, Review and analysis of biomass gasification models. Renew Sust Energ Rev 14:2841–2851

Mochizuki Y, Ma J, Kubota Y, Uebo K, Tsubouchi N (2020) Production of high-strength and low-gasification reactivity coke from low-grade carbonaceous materials by vapor deposition of tar. Fuel Process Technol 203:106384

Uemura Y, Omar W, Othman NA, Yusup S, Tsutsui T (2011) Torrefaction of oil palm EFB in the presence of oxygen. Fuel 103:156–160

Tumuluru JS, Sokhansanj S, Hess JR, Wright CT, Boardman RD (2011) A review on biomass torrefaction process and product properties for energy applications. Ind Biotechnol 7:384–401

Ciolkosz D, Wallace R (2011) A review of torrefaction for bioenergy feedstock production. Biofuels. Bioprod Bioref 5:317–329

Nargotra P, Sharma V, Gupta M, Kour S, Bajaj BK (2018) Application of ionic liquid and alkali pretreatment for enhancing saccharification of sunflower stalk biomass for potential biofuel-ethanol production. Bioresour Technol 267:560–568

Weiland JJ, Guyonnet R (2003) Study of chemical modifications and fungi degradation of thermally modified wood using DRIFT spectroscopy. Holz Roh Werkst 61:216–220

Gohar P, Guyonnet R (1998) Development of the rectification process of wood at the industrial scale. The challenge safety and environment in wood preservation: Cannes-Mandelieu, 2–3 Feb. Wood preservation. International symposium, No. 4, Cannes-Mandelieu, France 174–183

Yan W, Acharjee TC, Coronella CJ, Vasquez VR (2009) Thermal pretreatment of lignocellulosic biomass. Environ Prog Sustain Energy 28:435–440

Inari GN, Petrissans M, Gerardin P (2007) Chemical reactivity of heat-treated wood. Wood Sci Technol 41:157–168

Acharya B (2013) Torrefaction and pelletization of different forms of biomass of ontario [MASc thesis]. University of Guelph, Canada

Bhuiyan RT, Hirai N, Sobue N (2001) Effect of intermittent heat treatment on crystallinity in wood cellulose. J Wood Sci 47:336–341

Funke A, Ziegler F (2010) Hydrothermal carbonization of biomass: a summary and discussion of chemical mechanisms for process engineering. Biofuels Bioprod Biorefin 4:160–177

Dastyar W, Raheem A, Zhao M, Yuan W, Li H, Ting ZJ (2019) Effects of ionic liquid-assisted pretreatment of heavy metal-contaminated biomass on the yield and composition of syngas production using noncatalytic and catalytic pyrolysis and gasification processes. ACS Sustain Chem Eng 7:22

Nargotra P, Sharma V, Bajaj BK (2019) Consolidated bioprocessing of surfactant-assisted ionic liquid-pretreated Parthenium hysterophorus L. biomass for bioethanol production. Bioresour Technol 289:121611

Sharma V, Nargotra P, Bajaj BK (2019) Ultrasound and surfactant assisted ionic liquid pretreatment of sugarcane bagasse for enhancing saccharification using enzymes from an ionic liquid tolerant Aspergillus assiutensis VS34. Bioresour Technol 285:121319

Reza MR, Coronella CJ (2011) Hydrothermal carbonization of lignocellulosic biomass. Reno, USA: University of Nevada; MASc Thesis

Klein-Marcuschamer D, Simmons BA, Blanch HW (2011) Techno-economic analysis of a lignocellulosic ethanol biorefinery with ionic liquid pretreatment. Biofuels Bioprod Biorefin 5:562–569

Chen WH, Liu SH, Juang TT, Tsai CM, Zhuang YQ (2015) Characterization of solid and liquid products from bamboo torrefaction. Appl Energy 160:829–835

Chen WH, Kuo PC (2010) A study on torrefaction of various biomass materials and its impact on lignocellulosic structure simulated by a thermogravimetry. Energy 35:2580–2586

Chen WH, Kuo PC (2011) Isothermal torrefaction kinetics of hemicellulose, cellulose, lignin and xylan using thermogravimetric analysis. Energy 36:6451–6460

Rousset P, Aguiar C, Labbe N, Commandre JM (2011) Enhancing the combustible properties of bamboo by torrefaction. Bioresour Technol 102:8225–8231

Wang L, Barta-Rajnai E, Skreiberg Q, Khalil R, Czégény Z, Jakab E, Barta Z, Grønli M (2018) Effect of torrefaction on physiochemical characteristics and grindability of stem wood, stump and bark. Appl Energy 227:137–148

Peng JH, Bi HT, Lim CJ, Sokhansanj S (2013) Study on density, hardness, and moisture uptake of torrefied wood pellets. Energy Fuel 27:967–974

Peng J, Wang J, Bi XT, Lim CJ, Sokhansanj S, Peng H, Jia D (2015) Effects of thermal treatment on energy density and hardness of torrefied wood pellets. Fuel Process Technol 129:168–173

Verhoeff F, Arnuelos AAI, Boersma AR, Pels JR, Lensselink J, Kiel JHA, Schukken H (2011) TorTech torrefaction technology for the production of solid bioenergy carriers from biomass and waste, (Report ECN-E--11-039), Energy Research Centre of the Netherlands, Netherlands

Phanphanich M (2010) Pelleting characteristics of torrefied forest biomass, (MSc thesis), University of Georgia, Georgia, USA

Ibrahim RHH, Darvell LI, Jones JM, Williams A (2013) Physicochemical characterisation of torrefied biomass. J Anal Appl Pyrolysis 103:21–30

Ogedengbe TI, Adamolekun TM, Olugbade TO (2016) Strategies for enhancing management of cell-phone waste In Nigeria. Proceedings of the 2016 Annual Conference of the School of Engineering & Engineering Technology (SEET), The Federal University of Technology, Akure, Nigeria 470-477

Olugbade TO, Mohammed TI (2015) Fuel developed from rice bran briquettes and palm kernel shells. Int J Energy Eng 5:9–15

Mohammed TI, Olugbade TO (2015) Characterization of briquettes from rice bran and palm kernel shell. Int J Mater Sci Innov 3:60–67

Mohammed TI, Olugbade TO (2015) Burning rate of briquettes produced from rice bran and palm kernel shells. Int J Mater Sci Innov 3:68–73

Akinnuli BO, Olugbade TO (2014) Development and performance evaluation of piggery and water hyacinth waste digester for biogas production. Int J Eng Innov Technol 3:271–276

Olugbade TO, Ojo OT (2018) Development and performance evaluation of an improved electric baking oven. Leonardo Electron J Pract Technol 33:189–206

Oke PK, Olugbade TO, Olaiya NG (2016) Analysis of the effect of varying palm kernel particle sizes on the calorific value of palm kernel briquette. Br J Appl Sci Technol 14:1–5

Olugbade T, Ojo O, Mohammed T (2019) Influence of binders on combustion properties of biomass briquettes: a recent review. Bioenergy Res 12:241–259

Batidzirai B, Mignot APR, Schakel WB, Junginger HM, Faaij APC (2013) Biomass torrefaction technology: techno-economic status and future prospects. Energy 62:196–214

Kung KS, Shanbhogue S, Slocum AH, Ghoniem AF (2019) A decentralized biomass torrefaction reactor concept. Part I: multi-scale analysis and initial experimental validation. Biomass Bioenergy 125:196–203

Kung KS, Ghoniem AF (2019) A decentralized biomass torrefaction reactor concept. Part II: mathematical model and scaling law. Biomass Bioenergy 125:204–211

Granados DA, Basu P, Chejne F (2017) Biomass torrefaction in a two-stage rotary reactor: modeling and experimental validation. Energy Fuel 31:5701–5709

Kung KS (2017) Design and validation of a decentralized biomass torrefaction system, PhD Thesis, Massachusetts Institute of Technology

Shah A, Darr MJ, Medic D, Anex RP, Khanal S, Maski D (2012) Techno-economic analysis of a production-scale torrefaction system for cellulosic biomass upgrading. Biofuels Bioprod Biorefin 6:45–57

Granados DA, Basu P, Chejne F, Nhuchhen DR (2017) Detailed investigation into torrefaction of wood in a two-stage inclined rotary torrefier. Energy Fuel 31:647–658

Onsree T, Sittisun P, Sasaki R, Tippayawong N (2018) Pyrolysis of corn residues: kinetic analysis using discrete distributed activation energy model. IOP Conf Ser Earth Environ Sci 159:1–7

Onsree T, Tippayawong N, Zheng A, Li H (2018) Pyrolysis behavior and kinetics of corn residue pellets and eucalyptus wood chips in a macro thermogravimetric analyzer. Case Stud Therm Eng 12:546–556

Tippayawong N, Rerkkriangkrai P, Aggarangsi P, Pattiya A (2018) Characterization of biochar from pyrolysis of corn residues in a semi-continuous carbonizer. Chem Eng Trans 70:1387–1392

Azargohar R, Soleimani M, Nosran S, Bond T, Karunakaran C, Dalai AK, Tabil LG (2019) Thermo-physical characterization of torrefied fuel pellet from co-pelletization of canola hulls and meal. Ind Crop Prod 128:424–435

Ghosh A, Santos AMS, Cunha JR, Dasgupta A, Fujisawa K, Ferreira OP, Lobo AO, Terrones M, Terrones H, Viana BC (2018) CO2 sensing by in-situ Raman spectroscopy using activated carbon generated from mesocarp of babassu coconut. Vib Spectrosc 98:111–118

Guizani C, Haddad K, Limousy L, Jeguirim M (2017) New insights on the structural evolution of biomass char upon pyrolysis as revealed by the Raman spectroscopy and elemental analysis. Carbon 119:519–521

Bala A, Singh B (2019) Development of an environmental-benign process for efficient pretreatment and saccharification of Saccharum biomasses for bioethanol production. Renew Energy 130:12–24

Bartocci P, Zampilli M, Bidini G, Fantozzi F (2018) Hydrogen-rich gas production through steam gasification of charcoal pellet. Appl Therm Eng 132:817–823

Chen D, Cen K, Cao X, Li Y, Zhang Y, Ma H (2018) Restudy on torrefaction of corn stalk from the point of view of deoxygenation and decarbonization. J Anal Appl Pyrolysis 135:85–93

Tong S, Xiao L, Li X, Zhu X, Liu H, Luo G, Worasuwannarak N, Kerdsuwan S, Fungtammasan B, Yao H (2018) A gas-pressurized torrefaction method for biomass wastes. Energy Convers Manag 173:29–36

Tippayawong N, Piboon P, Wongsiriamnuay T (2017) Parametric analysis of co-pelletization of corncobs and algae at moderate conditions. Proc WRI World Congr Comput Sci Inf Eng 2:1–5

Kleinschmidt CP (2011) Overview of international developments in torrefaction, Central European Biomass Conference, http://www.bioenergytrade

Koppejan J, Sokhansanj S, Melin S, Madrail S (2012) Status of overview of torrefaction technologies, IEA Bioenergy Task 32 report, http://www.iea.org

Ereev S, Patel M (2011) Recommended methodology and tool for cost estimates at micro level for new technologies. Prosuite Deliverable 2.2. Utrecht: Prosuite

Mul C, Meerwaarde V (2011) Torrefactie binnen de Toeleveringsketen (Impact of added value of torrefaction within the supply chain) e in Dutch. Delft TopTech e Master of Business in Energy Systems, Amsterdam

Grotheim K (2011) Torrefaction and densification of biomass fuels for generating electricity. Milestone 9 Report. Bepex International LLC, Minneapolis

Sequeira T, Santos M (2018) Renewable energy and politics: a systematic review and new evidence. J Clean Prod 192:553–568

Ramalho E, Sequeira T, Santos M (2018) The effect of income on the energy mix: are democracies more sustainable? Glob Environ Chang Human Pol Dimens 51:10–21

Lainez M, González JM, Aguilar A, Vela C (2018) Spanish strategy on bioeconomy: towards a knowledge based sustainable innovation. New Biotechnol 40:87–95

Dvořák P, Martinát S, Horst DV, Frantál B, Turečková K (2017) Renewable energy investment and job creation; a cross-sectoral assessment for the Czech Republic with reference to EU benchmarks. Renew Sust Energ Rev 69:360–368

Mengal P, Wubbolts M, Zika E, Ruiz A, Brigitta D, Pieniadz A, Black S (2018) Bio-based industries joint undertaking: the catalyst for sustainable bio-based economic growth in Europe. New Biotechnol 40:31–39

Zhou H, Qian Y, Kraslawski A, Yang Q, Yang S (2017) Life-cycle assessment of alternative liquid fuels production in China. Energy 139:507–522

Guo S, Zhao H, Zhao H (2017) The most economical mode of power supply for remote and less developed areas in China: power grid extension or micro-grid? Sustainability 9:910–928

Ribeiro JP, Tarelho L, Gomes AP (2018) Incorporation of biomass fly ash and biological sludge in the soil: effects along the soil profile and in the leachate water. J Soils Sediments 18:2023–2031

Berry P, Yassin F, Grosshans R, Lindenschmidt KE (2017) Surface water retention systems for cattail production as a biofuel. J Environ Manag 203:500–509

Dar JA, Rather MY, Subashree K, Sundarapandian S, Khan ML (2017) Distribution patterns of tree, understorey, and detritus biomass in coniferous and broad-leaved forests of western Himalaya, India. J Sustain For 36:787–805

Las-Heras-Casas J, López-Ochoa LM, Paredes-Sánchez JP, López-González LM (2018) Implementation of biomass boilers for heating and domestic hot water in multi-family buildings in Spain: energy, environmental, and economic assessment. J Clean Prod 176:590–603

Tippayawong N, Onsree T, Williams T, McCullough K, MacQueen B, Lauterbach J (2019) Catalytic torrefaction of pelletized agro-residues with Cu/Al2O3 catalysts. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-019-00535-w

Onsree T, Tippayawong N (2020) Torrefaction of maize residue pellets with dry flue gas. Bioenergy Res 13:358–368

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Olugbade, T.O., Ojo, O.T. Biomass Torrefaction for the Production of High-Grade Solid Biofuels: a Review. Bioenerg. Res. 13, 999–1015 (2020). https://doi.org/10.1007/s12155-020-10138-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-020-10138-3