Abstract

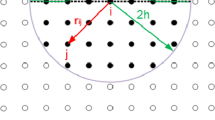

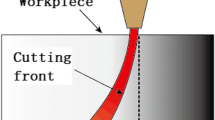

Waterjet cutting is an appealing technology for cutting thick materials with zones that must not be affected by heat. This paper presents computational fluid dynamics (CFD) and theoretical analyses to optimize the mixing of components by the multi-phase approach. Water, air, and abrasives are mixed in a mixing chamber. This modeling is used to predict the influence of air and abrasives on the mixing at different distances within the mixing tube. At the same time, particle tracking was conducted to monitor the erosion rate density at the nozzle wall. Results show that nozzle length has an effect on the mixing of water, air, and the abrasives, and that the velocity of the waterjet influences the erosion rate at the nozzle wall. The k-ɛ turbulence model was used for simulation of the abrasive coupled with air. This investigation reveals that the erosion in the nozzle body is higher at the initial zone and that as the length of the nozzle length increases, the volume fraction of air increases accordingly. The entrance of the orifice is affected by a highly pressurized water stream (with minimal particulate matter), which causes chipping at the leading edge. To reduce the turbulence inside the mixing chamber, the use of a vacuum assist could be helpful, but precautions should be taken in order that the abrasives do not escape from the mixing chamber.

Similar content being viewed by others

Reference

S. Xu and J. Wang, A study of abrasive water jet cutting of alumina ceramics with controlled nozzle oscillation, International Journal of Advanced Manufacturing Technology, 27 (2006), 693–702.

M. Hashish, Inside AWJ nozzles, WJTA American Waterjet Conference, Houston, Texas, USA. (2003), 1-D.

M. Nanduri, D. G. Taggart and T. J. Kim, The effect of system and geometric parameters on abrasive waterjet nozzle wear, International Journal of Machine Tools and Manufacturing, 42 (2002), 615–623.

S. Dosanjh and J. A.C. Humphery, The influence of turbulence on erosion by a particle-laden fluid jet, Wear, 102(4) (1984), 309–330.

R. Manu and N. R. Babu, An erosion-based model for abrasive waterjet turning of ductile materials, Wear, 266 (2009), 1091–1097.

U. Prisco and D’Onofrio, M.C., Three-dimensional CFD simulation of two-phase flow inside the abrasive water jet cutting head, International Journal for Computational Methods in Engineering Science and Mechanics, 9 (2008), 300–319.

L. S Kotousov, Measurement of the water jet velocity at the outlet of nozzles with different profiles. Technical Physics, 50(9) (2005), 1112–1118.

M. Hashish, Benifits of dynamic waterjet angle compensation, WJTA American Waterjet Conference, Houston, Texas, USA. (2007) 1-H.

M. Powell, Optimizing of UHP waterjet cutting heads, The Orifice, American WJTA conference and expo, Houston, Texas USA. (2007) 2-F.

H. V. Tafreshi and B. Pourdeyhimi, The Effects of nozzle geometry on waterjet breakup at high reynolds numbers, Experiments in Fluids, 35(4) (2003), 364–371.

Author information

Authors and Affiliations

Corresponding author

Additional information

Md. Golam Mostofa received his Bachelor degree in Mechanical Engineering from Bangladesh University of Engineering and Technology (BUET) in 2007. At present, he is pursuing his MS at Pusan National University (PNU). His research interests include industrial automation, system monitoring, computer-aided design and analysis, and optimizing mechanical system for best performance.

Rights and permissions

About this article

Cite this article

Mostofa, M.G., Kil, K.Y. & Hwan, A.J. Computational fluid analysis of abrasive waterjet cutting head. J Mech Sci Technol 24, 249–252 (2010). https://doi.org/10.1007/s12206-009-1142-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-009-1142-5