Abstract

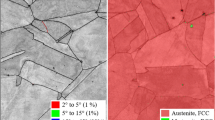

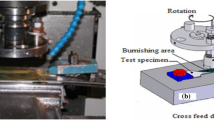

Ball burnishing, a mechanical surface treatment, is becoming more popular as a finishing process. As results ball burnishing is noticed as a very simple way of surface mirror finishing and surface work-hardening. Applying the optimal input parameters, a pre-machined surface roughness Ra about of 3.01 μm can be finished to approximately 0.30 μm, whereas an initial hardness HRA about 66.35 can be increased to 71.33. A metallographic observation and some measurement of micro-hardness show that the depth of penetration strengthened by plastic surface deformation (PSD) reaches 100 μm. Results analysis show that burnishing force, burnishing ball radius and number of ball burnishing tool passes have the most significant effects on both surface responses (Ra and HRA). For the generating of high surface qualities and strengthening superficial layers, an alternative to chip-forming process and heat treatments can be given by ball PSD process.

Similar content being viewed by others

References

M. H. EL-Axir, An investigation into roller burnishing, Int. J. Mach. Tools Manufact. (40) (2003) 1603–1617.

P. Zhang and J. Lindemann, Effect of roller burnishing on the high cycle fatigue performance on the high-strength wrought magnesium alloy AZ80, Scripta Mater. (52) (2005) 1011–1015.

A. C. E. Mendar, La technique du galetage, Métaux et déformation (47) (1978) 46–52.

F. Klocke and J. Lierman, Roller burnishing of hard turned surfaces, Int. J. Mach. Tools Manufact. (38) (1998) 419–423.

H. Hamadache, L. Laouar, k. Chaoui and N. E. Zeghib, Characteristics of Rb 40 steel superficial layer under ball and roller burnishing, J. Mater. Process. Technol. (180) (2006) 130–136.

A. M. Hassan, The effect of ball and roller burnish-ing on the surface roughness of some non-ferrous metals, J. Mater. Process. Technol. (72) (1997) 385–391.

F. J. Shiou and C. C. Hsu, Surface finish of hardened and tempered stainless tool steel using sequential ball grinding, ball burnishing and ball polishing processes on a machining center, J. Mater. Process. Technol. (205) (2008) 549–258.

H. Hamadache, A. Amirat and K. Chaoui, Effect of diamond ball burnishing on surface characteristics and fatigue strength of XC55 steel, Int. Review Mech. Eng. (1) (2008) 40–48.

R. Avillés, J. Albizuri, A. Rodriguez and L. N. Lopez de Lacalle, Influence of low-plasticity ball burnishing on the high-cycle fatigue strength of medium carbon AISI 1045 steel, Int. J. Fatigue (55) (2013) 230–244.

K. Zay, E. Maawad, H. G. Brokmeier, L. Wagner and Ch. Genzel, Influence of mechanical surface treatments on high cycle fatigue performance of TIMETAL 54M, Mater. Sci. Eng. A (528) (2011) 2554–2558.

E. Maawed, H. G. Brokmeier, L. Wagner, Y. Sano and Ch. Genzel, Investigation on the surface and near-surface characteristics of Ti-2.5Cu after various mechanical surface treatments, Surf. Coat. Technol. (205) (2011) 3644–3650.

H. Hamadache, L. Laouar and K. Chaoui, Comportement mécanique d’un acier au carbone sous l’effet du brunissage ou du galetage, Mécanique & Industrie (9) (2008) 183–191.

W. Grzesik and K. Zak, Modification of surface finish produced by hard turning using superfinishing and burnishing operations, J Mater. Process. Technol. (212) (2012) 315–322.

F. J. Shiou and C. C. Hsu, Freeform surface finish of plastic injection mold by using ball burnishing process, J. Mater. Process. Technol. (140) (2003) 248–254.

K. O. Low and K. J. Wong, Influence of ball burnishing on surface quality and tribological characteristics of polymers under dry sliding conditions, Tribol. Int. (44) (2011) 144–153.

L. N. López de Lacalle, A. RodrÍguez, A. Lamikiz, A. Celaya and R. Alberdi, Five-axis machining and burnishing of complex parts for the improvement of surface roughness, Mater. Manuf. Proces. (26) (2011) 997–1003.

L. N. Lopez de Lacalle, A. Lamiki J. Munoa and J. A. Sanchez, Quality improvement of ball-end milled sculptured surfaces by ball burnishing, Int. J. Mach. Tools Manufact. (45) (2005) 1659–1668.

L. Laouar, H. Hamadache, S. Saad, A. Bouchelaghem and S. Mekhilef, Mechanical surface treatment of steel-Optimization parameters of regime, Phy. Proc. (2) (2009) 1213–1221.

M. Korzynski and A. Pacana, Centerless burnishing and influence of its parameters on machining effects, J. Mater. Process. Technol. (9) (2010) 1217–1223.

H. Basak and H. H. Goktas, Burnishing process on al-alloy and optimization of surface roughness and surface hardness by fuzzy logic, Mat. Des. (30) (2009) 1275–1281.

A. Rodriguez, L. N. Lopez de Lacalle, A. Celaya, A. Lamikiz and J. Albizuri, Surface improvement of shafts by the deep ball-burnishing technique, Surf. Coat. Technol. (206) (2012) 2817–2824.

M. Salahshoor and Y. B. Guo, Surface integrity of biodegradable magnesium-calcium orthopedic implant by burnishing, J. Mech. Behav. Biomed. Mater. (4) (2011) 1888–904.

A. M. Hassan, H. F Al-Jalil and A. A. Ebied, Burnishing force and number of ball passes for the optimum surface finish of brass components, J. Mater. Process. Technol. (83) (1998) 176–179.

M. H. EL-Axir and M. M. EL-Khabeery, Influence of orthogonal burnishing parameters on surface characteristics for various materials, J. Mater. Process. Technol. (132) (2003) 82–89.

H. Luo, L. Wang and C. Zhang, Study of mechanism of the burnishing process with cylindrical polycrystalline diamond tools, J. Mater. Process. Technol. (180) (2006) 9–16.

M. H. El-Axir, O. M. Othman and A. M. Abodiena, Study on the inner surface finishing of aluminum al-loy 2014 by ball burnishing process, J. Mater. Process. Technol. (202) (2008) 435–442.

J. Goupy, Plans d’expériences pour surfaces de réponse, Ed Dunod, Paris (1999).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor In-Ha Sung

H. Hamadache is presently lecturer and researcher at the mechanical engineering department of Badji Mokhtar-Annaba University, Algeria. His current and previous research interests are material sciences and machining, material characterization. And mechanical surface treatment are investigated in order to perform the quality of machined work.

Rights and permissions

About this article

Cite this article

Hamadache, H., Zemouri, Z., Laouar, L. et al. Improvement of surface conditions of 36 Cr Ni Mo 6 steel by ball burnishing process. J Mech Sci Technol 28, 1491–1498 (2014). https://doi.org/10.1007/s12206-014-0135-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-014-0135-1