Abstract

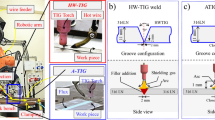

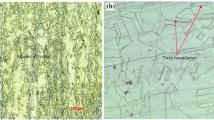

This article investigated the weldability, metallurgical and mechanical properties of Inconel 625 and AISI 316L stainless steel weldments obtained by continuous current (CC) and pulsed current (PC) gas tungsten arc welding (GTAW) processes employing ERNiCr-3 and ER2209 fillers. Microstructure studies showed the migrated grain boundaries at the weld zone of ERNiCr-3 weldments and multi-directional grain growth for ER2209 weldments. It was inferred from the tension tests that the fracture occurred at the parent metal of AISI 316L in all the cases. Charpy V-notch impact tests accentuated that the CCGTA weldments employing ERNiCr-3 filler offered better impact toughness of 77 J at room temperature. Further a detailed study has been carried out to analyze the structure — property relationships of these weldments using the combined techniques of scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS) analysis.

Similar content being viewed by others

References

K. S. Lee and Y. W. Chang, Deformation behavior of Zr-based bulk metallic glass in an under cooled liquid state under compressive loading, Met. Mater. Int., 11 (1) (2005) 53–57.

S. Alber, M. Abass, B. Zaghloul, A. Elrefaey and M. Ushio, Investigation of dissimilar joints between low carbon steel and Monel 400, Trans. JWRI, 29 (1) (2000) 21–28.

H. T. Lee, S. L. Jeng, C. H. Yen and T. Y. Kuo, Dissimilar welding of nickel-based alloy 690 to SUS 304L with Ti addition, J. Nucl. Mater., 335 (3) (2004) 59–69.

Y. H. Kim, G. S. Frankel, J. C. Lippold and G. Guaytima, Development of a chromium-free consumable for austenitic stainless steels—Part 1: monel (alloy 400) filler metal, Corrosion, 62 (1) (2006) 44–53.

L. R. Dreshfield, J. T. Moore and A. P. Bartolotta, Post-test examination of a pool boiler receiver, NASA, USA (1992).

X. Wu, R. S. Chandel, S. H. Pheow and H. Li, Brazing of inconel X-750 to stainless steel 304 using induction process, Mater Sci Eng. A, 288 (1) (2000) 84–90.

H. Naffakh, M. Shamanian and F. Ashrafizadeh, Dissimilar welding of AISI 310 austenitic stainless steel to nickel-based alloy Inconel 657, J. Mater. Process Tech., 209 (7) (2009) 3628–3639.

E. Farahani, M. Shamanian and F. Ashrafizadeh, A comparative study on direct and pulsed current gas tungsten arc welding of alloy 617, AMAE Int. J. on Manufacturing and Material Science, 2 (1) (2012).

H. Shah Hosseini, M. Shamanian and A. Kermanpur, Characterization of microstructures and mechanical properties of inconel 617/310 stainless steel dissimilar welds, Materials Characterization, 62 (4) (2011) 425–431.

J. N. Dupont, J. C. Lippold and S. D. Kiser, Welding metallurgy and weldability of nickel base alloys, John Wiley & Sons, USA (2009).

R. A. Patterson and J. O. Milewski, GTA weld crackingalloy 625 to 304L. Weld. Res. Suppl., 64 (8) (1985) 227–231.

K. D. Ramkumar, M. Parvateneni, D. Varun, R. Gopi, R. Ajay, N. Arivazhagan, S. Narayanan and K. G. Kumar, Characterization of microstructure and mechanical properties of inconel 625 and AISI 304 dissimilar weldments, ISIJ Int., 54 (4) (2014) 900–908.

S. L. Jeng, H. T. Lee, T. E. Weirich and W. P. Rebach, Microstructual study of the dissimilar joints of alloy 690 and SUS 304L stainless steel, Mater. Trans., 48 (3) (2007) 481–489.

K. D. Ramkumar, N. Arivazhagan and S. Narayanan, Effect of filler materials on the performance of gas tungsten arc welded AISI 304 and Monel 400, Mater. Des., 40 (2012) 70–79.

G. D. Janakiram, R. Venugopal, K. P. Rao, R. G. Madhusudhan and A. S. Rao, Effect of magnetic arc oscillation on microstructure and properties of Inconel 718 GTA welds, Trans. Indian. Inst. Met., 59 (2009) 85–97.

S. Sundaresan, G. D. J. Ram and G. M. Reddy, Microstructural refinement of weld fusion zones in alpha-beta titanium alloy using pulsed current welding, Mater. Sci. Eng. A, 262 (1999) 88–100.

S. Sundaresan and G. D. J. Ram, Use of magnetic arc oscillation for grain refinement of gas tungsten arc welds in α-β titanium alloys, Sci. Technol. Weld. Join, 4 (3) (1999) 151–160.

K. D. Ramkumar, P. D. Siddharth, S. S. Praveen, D. J. Choudhury, P. Prabaharan, N. Arivazhagan and M. A. Xavior, Influence of filler metals and welding techniques on the structure-property relationships of Inconel 718 and AISI 316L dissimilar weldments, Mater. Design., 62 (2014) 175–188.

T. P. S. Gill, M. Vijayalakshmi, J. B. Gnanamoorthy and K. A. Padmanabhan, Transformation of delta-ferrite during the post-weld heat treatment of type 316 L stainless steel weld metal, Weld. Res. Suppl. (1996) 122–128s.

E. J. Barnhouse and J. C. Lippold, Microstructure/property relationships in dissimilar welds between duplex stainless steels and carbon steels, Weld. Res. Suppl. (1998) 477–487s.

J. R. Davis, ASM specialty handbook: Stainless steels, ASM International, USA (1994).

S. A. Bashu, K. Singh and M. S. Rawat, Effect of heat treatment on mechanical properties and fracture behaviour of a 12CrMoV steel, Materials Science & Engineering A, 127 (1990) 7–15.

D. Carrouge, H. K. D. H. Bhadeshia and P. Woollin, Effect of δ-ferrite on impact properties of supermartensitic stainless steel heat affected zones, Sci. Technol. Weld. Join., 9 (2004) 377–389.

G. Alkan, D. Chae and S. J. Kim, Effect of δ ferrite on impact property of hot-rolled 12Cr-Ni steel, Materials Science & Engineering A, 585 (2013) 39–46.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Ji Weon Kim

K. Gokul Kumar received his Bachelor’s degree in Mechanical Engineering 1990 and Master’s Degree in Design during 2000 from University of Madras. He is currently pursuing his Ph.D. in the area of characterization of dissimilar weldments in VIT University. He has published five pioneered International journal papers. He is currently serving as Assistant Director (Students welfare) at VIT University.

K. Devendranath Ramkumar received his Bachelor’s degree in Mechanical Engineering in 2001 and Masters and Doctoral Degree from VIT University in the year 2004 and 2012 respectively. He has published more than 35 research papers in the pioneered International Journals.

N. Arivazhagan obtained his B.E. degree in Production Engineering from University of Madras in 1997. He received his Master’s Degree M.E. in Industrial Metallurgy from NIT Warangal in 2002 and PhD from IIT Roorkee in 2007. His areas of interest are dissimilar metal welding, high temperature corrosion and welding metallurgy. He has published more than 50 International Journal Papers. He is currently serving as Professor in the School of Mechanical & Building Sciences at VIT University.

Rights and permissions

About this article

Cite this article

Kumar, K.G., Ramkumar, K.D. & Arivazhagan, N. Characterization of metallurgical and mechanical properties on the multi-pass welding of Inconel 625 and AISI 316L. J Mech Sci Technol 29, 1039–1047 (2015). https://doi.org/10.1007/s12206-014-1112-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-014-1112-4