Abstract

A common drawback presented by several numerical rock-breaking studies was that the rocks beneath disc cutters were cut off excessively while the rocks between disc cutters remained, which usually resulted in a smaller cutter spacing than the proper value. To overcome this limitation, the constitutive equations of different rock parts were defined separately using VUMAT, an ABAQUS-based material subroutine. The constitutive model of rock was an application of the Drucker-Prager yield criterion coupled with the Lemaitre damage model. Full-scale rock-breaking tests on a rotary cutting machine were conducted, and 25 groups of orthogonal numerical simulations were carried out. By comparing the normal force, rolling force, and specific energy of numerical results with those of experimental results, the optimal values of the defined parameters D c1, k, and B were determined to be 9☓10-4, 0.1 and 0.8, respectively. With the presented numerical method and the determined parameters, the influences of cutter spacing on normal force, rolling force, and specific energy were studied. Both the normal and rolling forces of the first cutting generally remained constant, whereas the forces of the second cutting generally increased linearly with the cutter spacing. The optimal cutter spacing for the studied rock type (Hard sand rock collected from West Qinling tunnel) was approximately 72 mm, which was in accordance with the cutter spacing of the tunnel boring machine applied in this tunnel project.

Similar content being viewed by others

References

Norwegian soil and rock engineering association, Norwegian TBM Tunnelling, Norwegian Tunnelling Society, Oslo (1998) 112–113.

A. Bruland, Hard rock tunnel boring, Doctoral Thesis, Norwegian University of Science and Technology, Trondheim, Norway (1998).

The Robbins company, Robbins Tunnel Machine Projects List, Seattle (1991) 41.

A. M. Hansen, The history of TBM tunneling in Norway, Norwegian TBM Tunnelling (1998) 11.

J.-W. Cho, S. Jeon, H.-Y. Jeong and S.-H. Chang, Evaluation of cutting efficiency during TBM disc cutter excavation within a Korean granitic rock using linear-cutting-machine testing and photogrammetric measurement, Tunnelling and Underground Space Technology, 35 (2013) 37–54.

J.-W. Cho, S. Jeon, S.-H. Yu and S.-H. Chang, Optimum spacing of TBM disc cutters: A numerical simulation using the three-dimensional dynamic fracturing method, Tunnelling and Underground Space Technology, 25 (2010) 230–244.

N. Bilgin, M. Demircin, H. Copur, C. Balci, H. Tuncdemir and N. Akcin, Dominant rock properties affecting the performance of conical picks and the comparison of some experimental and theoretical results, International Journal of Rock Mechanics and Mining Sciences, 43 (2006) 139–156.

N. Bilgin, C. Feridunoglu, D. Tumac, M. Cinar, Y. Palakci, O. Gunduz and L. Ozyol, The performance of a full face tunnel boring machine (TBM) in Tarabya (Istanbul), Proceedings of 31st ITA-AITES World Tunnel Congress (2005) 821–826.

S. Eskikaya, N. Bilgin, C. Balci and H. Tuncdemir, From research to practice-development of rapid excavation technologies, Proceedings of 31st ITA-AITES World Tunnel Congress (2005) 435–441.

R. Gertsch, L. Gertsch and J. Rostami, Disc cutting tests in Colorado Red Granite: Implications for TBM performance prediction, International Journal of Rock Mechanics and Mining Sciences, 44 (2007) 238–246.

L. Ozdemir and B. Nilsen, Recommended laboratory rock testing for TBM projects, AUA News, 14 (1999) 21–35.

R. Snowdon, M. Ryley and J. Temporal, A study of disc cutting in selected British rocks, International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, Elsevier (1982) 107–121.

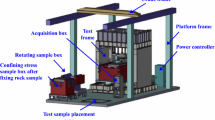

C. Qiwei, L. Fengyuan and H. Weifeng, Development of experimental system for rock-breaking mechanism of TBM disc cutters, Tunnel Construction, 33 (2013) 437–442.

J. Rostami, Hard rock TBM cutterhead modeling for design and performance prediction, Geomechanics and Tunnelling, 1 (2008) 18–28.

J. Rostami and L. Ozdemir, A new model for performance prediction of hard rock TBMs, Proceedings of the Rapid Excavation and Tunneling Conference, Society for Mining, Metallogy & Exploration, Inc. (1993) 793–793.

H. T. N. Bilgin, C. Balci, H. Çopur and S. Eskikaya, A model to predict the performance of tunnelling machines under stressed conditions, Proceedings of AITES-ITA 2000 World Tunnel Congress (2000) 47–53.

H. Y. Liu, S. Q. Kou, P. A. Lindqvist and C. A. Tang, Numerical simulation of the rock fragmentation process induced by indenters, International Journal of Rock Mechanics and Mining Sciences, 39 (2002) 491–505.

S. K. H. K. P.-A. L. C. A. Tang, Rock fragmentation mechanisms induced by a drill bit, International Journal of Rock Mechanics and Mining Sciences, 41 (2004) 527–532.

Q. Gong, Y. Jiao and J. Zhao, Numerical modelling of the effects of joint spacing on rock fragmentation by TBM cutters, Tunnelling and Underground Space Technology, 21 (2006) 46–55.

Q. Gong, J. Zhao and A. Hefny, Numerical simulation of rock fragmentation process induced by two TBM cutters and cutter spacing optimization, Tunnelling and Underground Space Technology, 21 (2006) 263.

Q.-M. Gong, J. Zhao and Y.-Y. Jiao, Numerical modeling of the effects of joint orientation on rock fragmentation by TBM cutters, Tunnelling and Underground Space Technology, 20 (2005) 183–191.

T. Qing, Z. Kui, X. Yimin, W. Kai and N. Weidong, Threedimensional simulation of rock breaking by TBM cutter, Journal of Shandong University (Engineering Science), 39 (2009) 72–77 (in Chinese).

J. Huo, W. Sun, L. Guo, Z. Li and X. Zhang, Numerical simulation of the rock fracture process induced by multidisc-cutters and cutter spacing design, Journal of Harbin Engineering University, 33 (2012) 96–99 (in Chinese).

Q. Tan, N. Yi, Y. M. Xia, Z. Xu, Y. Zhu and J. Song, Research on rock dynamic fragmentation characteristic by TBM cutters and cutter spacing optimization, Chinese Journal of Rock Mechanics and Engineering, 31 (2012) 2453–2464 (in Chinese).

L. Jianqin, Z. Bin, G. Wei and W. Lei, Numerical analysis on rotary rock breaking performance of TBM disc cutter, Journal of Shenyang University of Technology, 36 (2014) 51–56 (in Chinese).

M. Zhenze, L. Haibo, Z. Qingchun, H. Enguang, Z. Fei, Z. Xiaoming and Z. Xu, Research on numerical simulation of rock breaking using TBM disc cutters based on UDEC method, Rock and Soil Mechanics, 33 (2012) 1196–1202 (in Chinese).

J. Rojek, E. Onate, C. Labra and H. Kargl, Discrete element simulation of rock cutting, International Journal of Rock Mechanics and Mining Sciences, 48 (2011) 996–1010.

S. H. Baek and H. K. Moon, A numerical study on the rock fragmentation by TBM cutter penetration, Tunnel and Underground Space (J. of Korean Society for Rock Mechanics), 13 (2003) 444–454 (in Korean).

C. Weizhong, W. Guojun and J. Shanpo, Application of ABAQUS in Tunnelling and Underground engineering, China Water Power Press, Beijing (2010) (in Chinese).

C. Mingxiang, Elasticity and plasticity, Science Press (2007) (in Chinese).

W. Yuhou, Z. Jiannan, W. He, S. Hong, L. Feng and Z. Kaijun, Optimal analysis for cutter space of linear cutter machine based on ABAQUS, Journal of Shenyang Jianzhu University (Natural Science), 28 (2012) 927–931 (in Chinese).

M. Cigla, S. Yagiz and L. Ozdemir, Application of tunnel boring machines in underground mine development, 17th International Mining Congress and Exhibition of Turkey (2001) 155–164.

L. Ozdemir, CSM computer model for TBM performance prediction, Colorado School of Mines, USA (2003).

X. Xiaohe and Y. Jing, Theory of rock fragmentation, China Coal Industry Publishing House (1984) (in Chinese).

F. Dunne and N. Petrinic, Introduction to computional plasticity, Oxford University Press, New York (2005).

J. Lemaitre, A continuous damage mechanics model for ductile fracture, Journal of Engineering Materials and Technology, 107 (1985) 83–89.

R. Hambli, Comparison between Lemaitre and Gurson damage models in crack growth simulation during blanking process, International Journal of Mechanical Sciences, 43 (2001) 2769–2790.

S. W. Lee and F. Pourboghrat, Finite element simulation of the punchless piercing process with Lemaitre damage model, International Journal of Mechanical Sciences, 47 (2005) 1756–1768.

G. Qi, W. Zhengying and M. Hao, Numerical and experimental method to determine the boring diameters of a two-stage TBM cutterhead to prevent rock burst, Journal of Mechanical Science and Technology, 28 (2014) 4613–4620.

S.-O. Choi and S.-J. Lee, Three-dimensional numerical analysis of the rock-cutting behavior of a disc cutter using particle flow code, KSCE Journal of Civil Engineering, 19 (2015) 1129–1138.

F. F. Roxborough and H. R. Phillips, Rock excavation by disc cutter, International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, Elsevier (1975) 361–366.

Author information

Authors and Affiliations

Corresponding author

Additional information

Geng Qi received his B.E. from Shandong University in China in 2011. He is currently a Ph.D. candidate in the School of Mechanical Engineering at Xi’an Jiaotong University in China. His research interests include layout optimization and TBM cutter head design.

Wei Zhengying received her Ph.D. degree from the School of Mechanical Engineering at Xi’an Jiaotong University in China in 2003. Dr. Wei is a professor and doctoral supervisor in the School of Mechanical Engineering at Xi’an Jiaotong University in China. Her research interests include TBM cutter head design.

Meng Hao received his B.E. from Shandong University in China in 2013. He is currently a Master’s candidate in the School of Mechanical Engineering at Xi’an Jiaotong University in China. His research interests include TBM cutter head design.

Chen Qiao received his M.E. from Southwest Jiaotong University in China, in 2012. He is currently a Researcher in the State Key Laboratory of Shield Machine and Boring Technology. His research interests include TBM cutter head design.

Rights and permissions

About this article

Cite this article

Qi, G., Zhengying, W., Hao, M. et al. Numerical and experimental research on the rock-breaking process of tunnel boring machine normal disc cutters. J Mech Sci Technol 30, 1733–1745 (2016). https://doi.org/10.1007/s12206-016-0329-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-016-0329-9