Abstract

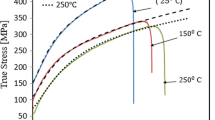

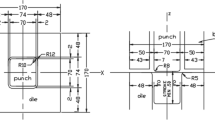

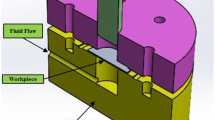

The formability of 1 mm thick AA5182 aluminum alloy sheets in deep drawing of square cups by hydroforming was studied. The influence of process parameters (peak pressure, pressure path, and blank holding force) on formability was investigated through numerical simulations and validated with experimental work. The experiments were designed using the Taguchi method. The minimum thickness in the formed cups (at the bottom corners) and the minimum corner radius that can be achieved were considered as the criteria for evaluation of formability. The peak pressure was the most important process parameter affecting thinning and the minimum corner radius that can be achieved. The variation of the pressure path had the least effect on formability. Regression models were developed for prediction of minimum thickness in the cup and the corner radius as a function of peak pressure and blank holding force.

Similar content being viewed by others

References

L. H. Lang, Z. R. Wang, D. C. Kang, S. J. Yuan, S. H. Zhang, J. Danckert and K. B. Nielsen, Hydroforming high lights: sheet hydroforming and tube hydroforming, J. Mater. Process. Tech., 151 (2004) 165–177.

S. K. Singh and D. R. Kumar, Effect of process parameters on product surface finish and thickness variation in hydro-mechanical deep drawing, J. Mater. Process. Tech., 204 (2008) 169–178.

M. Geiger, M. Merklein and M. Cojutti, Hydroforming of inhomogeneous sheet pairs with counter pressure, Prod. Eng. Res. Dev., 3 (2009) 17–22.

P. Hein and F. Vollertsen, Hydroforming of sheet metal pairs, J. Mater. Process. Tech., 87 (1999) 154–164.

K. Matthias, C. Manfred, T. A. Erman, R. Robert, S. Kerstin and T. Michael, Development of ultra high performance concrete dies for sheet metal hydroforming, Prod. Eng. Res. Dev., 2 (2008) 201–208.

S. Novotny and P. Hein, Hydroforming of sheet metal pairs from aluminum alloys, J. Mater. Process. Tech., 115 (2001) 65–69.

S. H. Zhang and J. Danckert, Development of hydromechanical deep drawing, J. Mater. Process. Tech., 83 (1998) 14–25.

T. Nakagawa, K. Nakagawa and H. Amino, Various applications of hydraulic counter pressure deep drawing, J. Mater. Process. Tech., 71 (1997) 160–167.

E. Onder and A. E. Tekkaya, Numerical simulation of various cross sectional workpieces sing conventional deep drawing and hydroforming technologies, Int. J. Mach. Tool. Manu., 48 (2008) 532–542.

S. G. Desai and P. P. Date, On the quantification of strain distribution in drawn sheet metal products, J. Mater. Process. Tech., 177 (2006) 439–443.

D. Y. Yang, J. B. Kim and D. W. Lee, Investigation into manufacturing of very long cups by hydromechanical deep drawing and ironing with controlled radial pressure, CIRP Annals, 44 (1995) 255–258.

M. Sasawat and K. Muammer, Fabrication of microchannel arrays on thin metallic sheet using internal fluid pressure: Investigations on size effects and development of design guidelines, J. Power Sources, 175 (2008) 363–371.

M. H. Hojjati, M. Zoorabadia and S. J. Hosseinipour, Optimization of superplastic hydroforming process of aluminium alloy 5083, J. Mater. Process. Tech., 205 (2008) 482–488.

T. J. Kim, D. Y. Yang and S. S. Han, Numerical modeling of the multi-stage sheet pair hydro forming process, J. Mater. Process. Tech., 151 (2004) 48–53.

H. Z. Shi, X. Z. Li, T. W. Zhong and X. Yi, Technology of sheet hydroforming with a movable female die, Int. J. Mach. Tool. Manuf., 43 (2003) 781–785.

K. P. Rao and J. J. Wei, Performance of a new dry lubricant in the forming of aluminum alloy sheets, Wear, 249 (2001) 86–93.

B. H. Lee, Y. T. Keum and R. H. Wagoner, Modeling of the friction caused by lubrication and surface roughness in sheet metal forming, J. Mater. Process. Tech., 130–131 (2002) 60–63.

R. Shivpuri and W. Zhang, Robust design of spatially distributed friction for reduced wrinkling and thinning failure in sheet drawing, Mater. Design, 30 (2009) 2043–2055.

B. J. Kim, K. H. Choi, K. S. Park, C. J. Van Tyne and Y. H. Moon, Effect of surface defects on hydroformability of aluminum alloys, Key Eng. Mat., 340–341 (2007) 587–592.

B. S. Kang, B. M. Son and J. Kim, A comparative study of stamping and hydroforming processes for an automobile fuel tank using FEM, Int. J. Mach. Tool. Manu., 44 (2004) 87–94.

Y. S. Shin, H. Y. Kim, B. H. Jeon and S. I. Oh, Prototype tryout and die design for automotive parts using welded blank hydroforming, J. Mater. Process. Tech., 130–131 (2002) 121–127.

O. Kreis and P. Hein, Manufacturing system for the integrated hydroforming, trimming and welding of sheet metal pairs, J. Mater. Process. Tech., 115 (2001) 49–54.

M. Geiger, M. Vahl, S. Novotny and S. Bobbert, Process strategies for sheet metal hydroforming of lightweight components, P. I. Mech. Eng., 215/B (2001) 967–976.

W. Liu, G. Liu, X. Cui, Y. Xu and S. Yuan, Formability influenced by process loading path of double sheet hydro-forming, T. NonFerr. Met. Soc., 21 (2011) 465–469.

G. Peter and E. Metin, Process control at the sealing line during sheet metal hydroforming, Prod. Eng. Res. Dev., 2 (2008) 3–8.

H. S. Halkaci, M. Turkoz and M. Dilmec, Enhancing form-ability in hydromechanical deep drawing process adding a shallow drawbead to the blank holder, J. Mater. Process. Tech., 214 (2014) 1638–1646.

A. H. Elkholy and O. M. Al-Hawaj, Collapse pressure and strength analysis of hydroformed circular plates, Int. J. Adv. Manuf. Technol., 18 (2001) 79–88.

M. A. Karkoub, Prediction of hydroforming characteristics using random neural networks, J. Intel. Manuf., 17 (2006) 321–330.

A. Ahmad and R. E. Mohammad, Pressure estimation in the hydroforming process of sheet metal pairs with the method of upper bound analysis, J. Mater. Process. Tech., 209 (2009) 2270–2276.

D. A. Oliveira, M. J. Worswick, M. Finn and D. Newman, Electromagnetic forming of aluminum alloy sheet: Free-form and cavity fill experiments and model, J. Mater. Process. Tech., 170 (2005) 350–362.

A. Nader, P. Farhang and C. John, Forming of AA5182-O and AA5754-O at elevated temperatures using coupled thermo-mechanical finite element models, Int. J. Plasticity, 23 (2007) 841–875.

B. Modi and D. R. Kumar, Development of a hydroforming set up for deep drawing of square cups with variable blank holding force technique, Int. J. Adv. Manuf. Technol., 66 (2013) 1159–1169.

D. C. Chen and C. F. Chen, Use of taguchi method to develop a robust design for the shape rolling of porous sectioned sheet, J. Mater. Process. Tech., 177 (2006) 104–108.

M. J. Davidson and K. Balasubramanian, Experimental investigation on flow-forming of AA6061 alloy-A Taguchi approach, J. Mater. Process. Tech., 200 (2008) 283–287.

A. K. Sharma and D. K. Rout, Finite element analysis of sheet hydromechanical forming of circular cup, J. Mater. Process. Tech., 209 (2009) 1445–1453.

B. Modi and D. R. Kumar, Effect of friction and lubrication on formability of AA5182 alloy in hydroforming of square cups, Mater. Sci. Forum, 762 (2013) 621–626.

R. Padmanabhan, M. C. Oliveira, J. L. Alves and L. F. Menezes, Influence of process parameters on the deep drawing of stainless steel, Finite Elem. Anal. Des., 43 (2007) 1062–1067.

F. Barlat and J. I. Lian, Plastic behavior and stretchability of sheet metals. Part-I: A yield function for orthotropic sheets under plane stress conditions, Int. J. Plasticity, 5 (1989) 51–56.

K. P. Rao and C. L. Xie, A comparative study on the performance of boric acid with several conventional lubricants in metal forming processes, Tribol. Int., 39 (2006) 663–668.

M. Javadi and M. Tajdari, Experimental investigation of the friction coefficient between aluminum and steel, Mater. Sci., 24 (2006) 305–310.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Young Whan Park

Bharatkumar Modi was a research scholar in the Department of Mechanical Engineering, Indian Institute of Technology Delhi, India when this work was carried out. He is presently a Professor of Mechanical Engineering, Nirma University, Ahmedabad, India.

D. Ravi Kumar is a Professor of Mechanical Engineering, Indian Institute of Technology Delhi, India. His research interests include sheet metal forming, finite element analysis, hydroforming, lightweight materials and severe plastic deformation techniques.

Rights and permissions

About this article

Cite this article

Modi, B., Kumar, D.R. Optimization of process parameters to enhance formability of AA 5182 alloy in deep drawing of square cups by hydroforming. J Mech Sci Technol 33, 5337–5346 (2019). https://doi.org/10.1007/s12206-019-1026-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-1026-2