Abstract

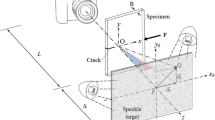

To analyze the stress of functionally graded materials (FGMs) through an experiment, transparent homogeneous FGMs (THFGMs) with similar theoretical and physical properties need to be created. This study developed such THFGMs and proposed a method for determining their stress intensity factors (SIFs) and T-stresses via photoelastic experiments. The Young’s modulus and Poisson’s ratio of these THFGMs linearly change along the physical variation direction, and the shear modulus varies almost linearly. The SIFs and T-stresses were obtained for the central and edge cracks in finite rectangular FGM plates with linear variations in the shear modulus under constant density along the direction of the crack under mode I loading. The SIFs and T-stresses can be obtained using the exponential and linear variation in the stress fields, even if the physical properties of FGM plates show linear variation in the shear modulus. The characteristics of the experimental SIFs obtained in this study generally agree with those of theoretical SIFs reported in previous research. For center crack tips, the SIFs at the hard right crack tip were greater than those at the soft left crack tip. For edge crack tips, when a/W < 0.35, the SIFs were lower than the homogeneous materials. By contrast, when a/W > 0.35, the SIFs were greater than the homogeneous materials. The experimental T-stresses for the center crack agreed well with the numerical T-stresses reported in previous research. For the edge crack, when a/W ≤ 0.3, the experimental T-stresses agreed with the numerical T-stress, but when a/W ≥ 0.4, considerable differences were observed between the experimental and numerical T-stresses. Where a(a) denotes the crack length for edge cracks or half the crack length for center cracks, and W is the width of the specimen. Experimental results coincide well with those reported in the literature, except for the T-stresses for edge crack when a/W > 0.3. Therefore, the THFGMs, which are new FGMs developed in this study, can be effectively used in experimental fracture analysis.

Similar content being viewed by others

References

F. Delale and F. Erdogan, The crack problem for a nonhomogeneous plane, J. Appl. Mech., 50 (1983) 67–80.

F. Erdogan, Fracture mechanics of functionally graded materials, Com. Eng., 5(7) (1995) 753–779.

P. R. Marur and H. Tippur, Numerical analysis of crack-tip fields in functionally graded materials with a crack normal to the elastic gradient, Int. J. Solids and Structures, 37(38) (2000) 5353–5370.

J. H. Kim and G. H. Paulino, Consistent formulations of the interaction integral method for fracture of functionally graded materials, J. Appl. Mech., 72 (2005) 351–364.

J. E. Dolbow and M. Gosz, On the computation of mixed-mode stress intensity factors in functionally graded materials, Int. J. Solids and Struct., 39(9) (2002) 2557–2574.

H. Okada, S. Kadowaki, M. Suzuki and Y. Yusa, J-integral computation for elastic-plastic materials with spatially varying mechanical properties, Int. J. Solids and Struct., 207(15) (2019) 181–202.

R. J. Butcher, C.-E. Rousseau and H. V. Tippur, A functionally graded particulate composite: preparation, measurements and failure analysis, Acta. Mater., 47(1) (1998) 259–268.

C. E. Rousseau and H. V. Tippur, Compositionally graded materials with cracks normal to the elastic gradient, Acta. Mater., 48 (2000) 4021–4033.

H. Li, J. Lambros, B. A Cheeseman and M. H. Santare, Experimental investigation of the quasi-static fracture of functionally graded materials, Int. J. Solids Struct., 37 (2000) 3715–3732.

M. Jaroniek, Experimental model of fracture of functionally graded materials, J. Theo. and Appl. Mech., 48(1) (2010) 71–86.

A. Ulukoy, M. Topcu and S. Tasgetiren, Experimental investigation of aluminum matrix functionally graded material: Microstructural and hardness analyses, fretting, fatigue, and mechanical properties, J. Eng. Tri.-SAGA, 230(2) (2016) 143–155.

L. D. Bobbio, R. A. Otis, J. P. Borgonia, R. P. Dillon, A. A. Shapiro, Z.-K. Liu and A. M. Beese, Additive manufacturing of a functionally graded material from Ti-6Al-4V to invar: experimental characterization and thermodynamic calculations, Acta. Mater., 127(1) (2017) 133–142.

K. H. Lee, Analysis of a transiently propagating crack in functionally graded materials under mode I and II, Int. J. Eng.Sci., 47 (2009) 852–865.

K. H. Lee, Y. J. Lee and S. B. Cho, Characteristics of a transiently propagating crack in functionally graded materials, J. Mech. Sci. Tech., 23 (2009) 1306–1322.

K. H. Lee, A. Shukla, V. Parameswaran, V. B. Chalivendary and J. S. Hawong, Static and dynamic fracture analysis for inter face crack of isotropic-orthotropic biomaterial, KSME Int. J., 16 (2002) 165–174.

H. S. Lim, D. C. Shin and J. S. Hawong, Analysis for interior stress in various curvature radiuses on D-ring seal using hybrid photoelastic experimental method, J. of Mechanical Science and Technology, 31(8) (2017) 3679–3683.

M. Isida, Effect of width and length on stress intensity factor of internally cracked plate under various boundary conditions, Int. J., 7(3) (1971) 301–316.

X. Wang, Elastic T-stress for cracks in test specimens subjected to non-uniform stress distributions, Eng. Frac. Mech., 69 (2002) 1339–1352.

Y. Murakami, Stress Intensity Factors Hand Book 2, Pergamon Press (1987) 916–917.

F. Erdogan and B. H. Wu, The surface crack problem for a plate with functionally graded properties, J. App. Mech., 64 (1997) 449–456.

R. J. Sanford, Principles of Fracture Mechanics, Pearson Education, Inc. (2002).

Acknowledgments

This research was supported by a National Research Foundation of Korea (NRF) grant funded by the Korean government (2015M3D1A1069719, 2019R1F1A105739812).

Author information

Authors and Affiliations

Corresponding author

Additional information

Kwang-Ho Lee received his Ph.D. degree from Yeungnam University in 1993. He is currently a Professor at the School of Automotive Engineering at Kyungpook National University in Korea. He also worked in KOMSCO as an engineer and researcher from March 1982 to February 1996. He is interested in analyzing fracture and stress on composite, interface, nano, and functionally graded materials using theoretical mechanics and experimental method (photoelasticity and mechanoluminescence). His major interest lies in analyzing dynamic crack tip fields.

Bum-Su Kim received his B.S. degree from the School of Automotive Engineering in Kyungpook National University in 2020. He is currently a M.S. candidate under Prof. Lee at the same school. His research interests include FEM analysis and photoelastic experiments.

Ji Sik Kim received his Ph.D. from POSTECH in 1998. He is currently a Professor at the School of Nano and Advanced Materials Engineering at the Kyungpook National University in Korea. His research interests lie in the intelligent optimization of functional and structural materials and their applications around mechanoluminescence.

Rights and permissions

About this article

Cite this article

Lee, K.H., Kim, B.S. & Kim, J.S. Fabrication of transparent homogeneous functionally graded materials and crack analysis by photoelasticity. J Mech Sci Technol 35, 3919–3929 (2021). https://doi.org/10.1007/s12206-021-0805-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-021-0805-8