Abstract

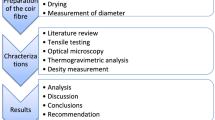

Coconut fibres were subjected to chemical treatment to obtain softer and finer fibres, suitable to blend with other finer fibre like jute. The chemical softening recipe was optimized using Box-Behnken design of experiments as 40 % Na2S, 10 % NaOH and 6 % Na2CO3, which notably reduced the fineness (33 %) and flexural rigidity (74 %) and improved tensile property of coconut fibre. Effect of softening of coconut fibre on its process performance was studied in high speed mechanized spinning system at different blend ratios with jute. Blending with jute assists in spinning of coconut fibre to produce yarn of 520 tex at production rate of 5-6 kg/h, as compared to 15 kg/day for hand spun 5300 tex raw coconut fibre yarn in manual system. Analysis of blended yarn structure in terms of packing density, radial distribution of fiber components (SEM) and mass irregularity were investigated. SEM shows yarns made from softened coconut fibre -jute blends are more compact than raw coconut fibre -jute blend yarns. Coconut fibres were preferentially migrated to core of the yarn. Major yarn properties viz., tensile strength, and flexural rigidity of raw and chemically softened blended yarns were compared against their finest possible 100 % coconut fibre yarn properties. Yarn made up to 50:50 chemically softened coconut fibre-jute blend showed much better spinning performance, and having superior property in terms of reduced diameter, higher compactness, strength, initial modulus and less flexural rigidity than 100 % raw, 100 % chemically softened coconut fibre rope, and raw coconut fibre-jute blend yarns.

Similar content being viewed by others

References

“Jute, Kenaf, Sisal, Abaca, Coir and Allied Fibers Statistics”, Food and Agriculture Organization of the United Nations, 2013.

D. C. Senan, “Occupational Diseases and Health Awareness through Multimedia: A Case Study among Women at Risk Employed in Coir Retting in Kerela”, Partridge Publishing, India, 2014.

J. E. G. van Dam, “Common Fund for Commodities”, p.17, 27, 35, Netherland, 2002.

NIIRBCE, “The Complete Book on Coconut & Coconut Products (Cultivation and Processing)”, p.171, Asia Pacific Business Press Inc., 2012.

Coir machines and Coir Products, www.2mecoir. com/ (accessed 03.05.2016).

Coir Machines and Coir Products, www. kumarancoir. com/ (accessed 03.05.2016).

K. P. Chellamani, D. Chattopadhyay, and U. S. Sarma, Asian Text. J., 55, 66 (2006).

I. R. Anto, P. K. Ravi, and U. S. Sarma, Coir News, 27, 19 (1998).

G. Basu, L. Mishra, S. Jose, and A. K. Samanta, Ind. Crop Prod., 77, 66 (2015).

G. E. P. Box and D. W. Behnken, Technometrics, 2, 455 (1960).

A. Das and R. Chakraborty, Indian J. Fibre Text. Res., 38, 237 (2013).

E. Tholkappiyan, D. Sarvanan, R. Jagasthitha, T. Angeswari, and V. T. Surya, Indian J. Fibre Text. Res., 40, 19 (2015).

H. P. Stout, “Fibre and Yarn Quality in Jute Spinning”, p.46, The Textile Institute, Manchester, UK, 1988.

G. Bose, Final Report, NAIP, Component-II, NIRJAFT, ICAR, Kolkata, India, 2013.

BIS 1670, Bureau of Indian Standard, 1970.

BIS 6359, Bureau of Indian Standard, 1972.

G. Basu, A. N. Roy, K. K. Satapathy, S. M. J. Abbas, L. Mishra, and R. Chakraborty, Ind. Crop Prod., 36, 33 (2011).

ASTM D 2654-76, American Society for Testing and Materials, 1978.

G. Basu, S. S. De, and A. K. Samanta, Ind. Crop Prod., 29, 281 (2009).

BIS 271, Bureau of Indian Standard, 3rd Revision, 1987.

A. Chaudhari and G. Basu, Indian J. Fibre Text. Res., 26, 239 (2001).

P. W. Caslene, J. Text. Inst., 41, T159 (1950).

K. R. Salhotra, “Spinning of Manmade and Blends on Cotton System”, pp.21–22, The Textile Association (India), Mumbai, India, 1983.

E. G. Chambers, “Statistical Calculation for Beginners”, pp.37, 60-63, 156-157, Cambridge University Press, 1958.

B. C. Budett and J. G. Robert, J. Soc. Dyer Colour., 101, 53 (1985).

F. J. W. Herman, “Kraft Pulping Theory and Practice”, p.15, Lockwood Publishing Co. Inc., New York, 1967.

D. Sur, A. C. Chakravarty, and S. B. Bandyopadhyay, J. Text. Inst., 73, 80 (1982).

D. Sur, A. C. Chakravarty, and S. B. Bandyopadhyay, J. Text. Inst., 66, 180 (1975).

E. Oxotoby, “Fibre Migration and Displacement in Spun Yarn Technology”, pp.112–114, Butterworths, London, 1987.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mishra, L., Basu, G. & Samanta, A.K. Effect of chemical softening of coconut fibres on structure and properties of its blended yarn with jute. Fibers Polym 18, 357–368 (2017). https://doi.org/10.1007/s12221-017-6614-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-017-6614-0