Abstract

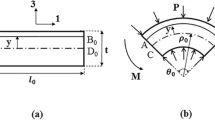

The importance of an accurate material modeling for the accuracy and reliability of sheet forming simulations has become increasingly evident during the last years. More advanced material models have, however, to be supported by novel methods for material characterization. The recent eight parameter yield functions Yld2000-2d and BBC2003 demand, besides data from the ordinary uniaxial tensile tests, also equibiaxial data. In the present paper a Viscous Pressure Bulge (VPB) test is described. The test yields the equibiaxial stress point and r-value, as well as a plastic hardening curve for large values of plastic strain. The test setup is based on an ARGUSS™ optical measuring system, and provides the desired result data in a very smooth and easy way. In order to verify the results from the current test, comparisons have been made with compression tests performed at Corus RD&T and hydraulic bulging tests performed at RWTH in Aachen. A discussion on how to determine the equibiaxial yield stress and how to transform the biaxial stress-strain curve to an effective stress-strain curve is included in the paper.

Similar content being viewed by others

References

Mattiasson K, Sigvant M (2004) Material characterization and modeling for industrial sheet forming simulations. In: Ghosh, Castro, Lee (eds) Proceedings of NUMIFORM 2004, AIP Conference Proceedings 712

Mattiasson K, Sigvant M (2005) On The Influence Of The Yield Locus Shape In The Simulation Of Sheet Stretch Forming. In: Smith LM et al. (eds) Proceedings of NUMISHEET 2005, AIP Conference Proceedings 778

Mattiasson K, Sigvant M (2005) On the choice of yield criterion for industrial sheet forming simulations. Proceedings of IDDRG 2005, Besancon, France

Mattiasson K, Sigvant M (2006) New non-quadratic yield locus models and their influence on the accuracy of the FEA. In: Hora and Krauer (eds) Proceedings of FLC-Zurich 06, Numerical and experimental methods in prediction of forming limits in sheet forming and tube hydroforming processes, Zurich, Switzerland, pp. 61–63

Banabic D, Aretz H, Comsa DS, Paraianu L (2005) An improved analytical description of orthotropy in metallic sheets. Int J Plasticity 21:493–512

Barlat F, Brem JC, Yoon JW, Chung K, Dick RE, Lege DJ, Pourboghrat F, Choi S-H, Chu E (2003) Plane stress yield function for aluminium alloy sheets–Part I: theory. Int J Plasticity 19:1297–1319

Vegter H, van den Boogaard AH (2006) A plane stress yield function for anisotropic sheet material by interpolation of biaxial stress states. Int J Plasticity 22:557–580

Lee M-G, Kim D, Kim C, Wenner ML, Wagoner RH, Chung K (2005) Spring-back evaluation of automotive sheets based on isotropic-kinematic hardening laws and non-quadratic anisotropic yield functions – Part II: characterization of material properties. Int. J. Plasticity 21:883-914

Gutscher G, Wu HC, Ngaile G, Altan T (2004) Determination of flow stress for sheet metal forming using the viscous pressure bulge (VPB) test. J Mater Process Technol 146:1–7

Blumbach M, Bleck W, Noll R, Vrenegor J (2005) Online Fließkurvenermittlung im hydraulischen Tiefungs-versuch mit Hilfe des Laserlichtschnittverfahrens, 20. Aachener Stahlkolloquium, Aachen (in German)

Acknowledgements

The Swedish part of the project has been performed within the national research program MERA (Manufacturing Engineering Research Area) and OSAS (Olofström School of Automotive Stamping). Financial support has been provided by VINNOVA, Volvo Cars, and Saab Automobile.

The experimental work in connection to this study has been conducted at the Industrial Development Centre at Olofström, Sweden, at Corus RD & T in the Netherlands, and at RWTH, Aachen, Germany. The contributions by the personnel at these laboratories are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sigvant, M., Mattiasson, K., Vegter, H. et al. A viscous pressure bulge test for the determination of a plastic hardening curve and equibiaxial material data. Int J Mater Form 2, 235–242 (2009). https://doi.org/10.1007/s12289-009-0407-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-009-0407-y