Abstract

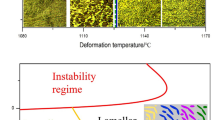

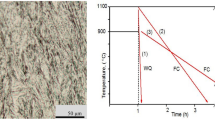

The high temperature deformation behaviour of cast and homogenised near α titanium alloy Titan 29A (M/s MIDHANI, India), equivalent to IMI 834 (M/s TIMET, UK) was studied towards developing a processing map. The processing map is interpreted in terms of the microstructural changes occurring during deformation, based on the values of a dimensionless parameter η which represents the energy dissipation through microstructural evolution processes. An instability criterion (ξ < 0) is applied to demarcate the flow instability regions in the processing map. Both the parameters (η and ξ) were computed from the experimental data generated by hot isothermal compression tests conducted at various temperature (T) and strain rate (έ) combinations T = 850-1100 °C and έ = 3 × 10−4 to 10 0/s. The deterministic domains observed in the investigated temperature and strain rate regime are attributed to continuous dynamic recrystallization of α lamella and dynamic recrystallization of β grains.

Similar content being viewed by others

References

Neal DF (1995) Alloy development. Titanium ‘ 95: Science and Technology: VIII World Conference on Titanium, Birmingham, UK, pp 2195–2204

Neal DF (1998) Development and Evaluation of high temperature titanium alloy IMI 834. VI world conference on titanium. France, pp 253–258

Farthing TW (1998) Designing with titanium. VI world conference on titanium. France pp 37–48

Noda T, Okabe M, Isobe S, Nishikiori S and Hattori H (1998) Development of high performance heat resistant near alpha titanium alloy compressor disc. Titanium ‘ 95- Science and Technology: VIII World Conference on Titanium. Birmingham, UK 2258–2264

Honnorat Y (1998) Ti alloys used in Turbojet Engines. VI world conference on titanium. France pp 365–379

Balasundar I, Sudhakara Rao M, Raghu T and Saha GG (2005) Shaft forging for stage # 3 high pressure compressor region of KAVERI Engine—A feasibility study. DMRL Technical Report: DMRL TR 494 2005 381, India

Balasundar I, Sudhakara Rao M, Rohatgi M, Raghu T, Kashyap BP (2010) DMM based approach to produce aeroengine discs. J Mach Form Technol 2:141–156

Boyer RR (1996) An overview on the use of titanium in the aerospace industry. Mater Sci Eng 213A:103–114

Bewlay BP, Gigliotti MFX, Utyashev FZ, Kaibyshev OA (2000) Superplastic roll forming of Ti alloys. Mater Des 21:287–295

Bewlay BP, Gigliotti MFX, Utyashev FZ, Kaibyshev OA (2003) Net-Shape manufacturing of aircraft engine disks by roll forming and hot die forging. J Mater Process Technol 135:324–329

Prasad YVRK, Sasidhara S (1997) Hot Working Guide—A Compendium of Processing maps. ASM International, Ohio

Li M, Pan H, Lin Y, Luo J (2007) High temperature deformation behaviour of near alpha Ti-5.6Al-4.8Sn-2.0Zr alloy. J Mater Process Technol 183:71–76

Niu Y, Hou H, Li M, Li Z (2008) High temperature deformation behaviour of near alpha Ti600 titanium alloy. Mater Sci Eng 492A:24–28

Seshacharyulu T, Medeiros SC, Frazier WG, Prasad YVRK (2000) Hot working of commercial Ti–6Al–4V with an equiaxed α–β microstructure: materials modeling considerations. Mater Sci Eng 284A:184–194

Seshacharyulu T, Medeiros SC, Frazier WG, Prasad YVRK (1998) Hot deformation mechanisms in Ti-6a1-4v Eli grade. Scr Mater 41:283–288

Jia W, Zenga W, Zhou Y, Liu J, Wang Q (2011) High-temperature deformation behavior of Ti60 titanium alloy. Mater Sci Eng 528A:4068–4074

Bate PS, Blackwell PL and Brooks JW (1998) Thermo-mechanical Processing of Titanium IMI 834. VI world conference on titanium, France pp 287–292

Wanjara P, Jahazi M, Monajati H, Yue S, Immarigeon JP (2005) Hot working behaviour of near alpha alloy IMI 834. Mater Sci Eng 396A:50–60

Wanjara P, Jahazi M, Monajati H, Yue S (2006) Influence of thermomechanical processing on microstructural evolution in near alpha alloy IMI 834. Mater Sci Eng 416A:300–311

Vo P, Jahazi M, Yue S, Bocher P (2007) Flow stress prediction during hot working of near alpha titanium alloys. Mater Sci Eng 447A:99–110

Zhou (1998) Constitutive modeling of the viscoplastic deformation in high temperature forging of titanium alloy IMI 834. Mater Sci Eng 245A:29–38

Wang X, Jahazi M, Yue S (2006) Substructure of high temperature compressed titanium alloy IMI 834. Mater Sci Eng 434A:88–193

Balasundar I, Raghu T, Kashyap BP (2012) Modeling the high temperature deformation behaviour of a near alpha titanium alloy with bi-modal microstructure. Mater Sci Forum 710:533–538

Balasundar I, Raghu T and Kashyap BP (2011) Modeling the deformation behaviour of near alpha titanium alloy with acicular microstructure. Processing of Int. Conf. on Materials and Materials Processing, IIT Kaharagpur, India

Humpreys FJ, Hatherly (2004) Recrystallisation and related annealing phenomenon, 2nd edn. Elsevier, Oxford

Wiess I, Semiatin SL (1999) Thermo-mechanical processing of alpha titanium alloys—an overview. Mater Sci Eng 263A:243–256

McQueen HJ, Bourell DL (1987) Hot workability of metals and alloys. JOM 39:28–35

Briottet L, Jonas JJ, Montheillet F (1996) A mechanical interpretation of the activation energy of high temperature deformation in two phase materials. Acta Mater 44:1665–1672

Gatek J (1988) Creep in metallic materials, Materials science monographs, vol 48. Elsevier, NY

Semiation SL, Seetharaman V, Wiess I (1997) Hot working of titanium alloys—An overview, Advance in the science and technology of titanium alloy processing. In: Wiess I, Srinivasan R, Bania PJ, Eylon D, Semiatin SL (eds), The minerals, Metals and Materials Society, Warrendale, PA pp. 3–73

Dieter GE (2003) Handbook of workability and process design. ASM International, Ohio

Lütjering G, Willams JC (2007) Titanium, 2nd edn. Springer, Berlin

Donachie MJ Jr (2000) Titanium—A technical Guide, 2nd edn. ASM international, Ohio

Banerjee D, Krishnan RV (1981) Challenges in alloy design—Titanium for aerospace industry. Proc Indian Acad Sci (Eng Sci) 4:21–39

Vander Voort GE (1984) Metallography principles and practice. McGraw-Hill, NY

Song H-W, Zhang S-H, Cheng M (2009) Dynamic globularisation kinetics during hot working of a two phase titanium alloy with a colony alpha microstructure. J Alloys Compd 480:922–927

Cheng-bao WU, He YANG, Xiao-guang FAN, Zhi-chao SUN (2011) Dynamic globularisation kinetics during hot working of TA15 titanium alloy with colony microstructure. Trans Nonferrous Soc China 21:1963–1969

Wanga K, Zenga W, Zhao Y, Lai Y, Zhoua Y (2010) Dynamic globularization kinetics during hot working of Ti-17 alloy with initial lamellar microstructure. Mater Sci Eng 527A:2559–2566

Margolin H and Cohen P (1980) Evolution of equiaxed alpha morphology of phases in Ti-6Al-4V alloy, Titanium 80—Science and Technology. Fourth International Conference on Titanium, Kyoto, Japan pp 1555–1561

Margolin H and Cohen P (1980) Kinetics of Recrystallization of alpha in Ti-6Al-4V, Titanium 80 –Science and Technology. Fourth International Conference on Titanium, Kyoto, Japan pp 2991–2997

Weiss I, Froes FH, Eylon D, Welsch GE (1986) Modification of alpha morphology in Ti-6Al-4V by thermomechanical processing. Metall Trans A17:1935–1947

Park CH, Park K-T, Shin DH, Lee CS (2008) Microstructural mechanisms during dynamic globularization of Ti-6Al-4V Alloy. Mater Trans 49:2196–2200

Semiatin SL, Thomas JF, Dadras P (1983) Processing-Microstructure relationships for Ti-6Al-2Sn-4Zr-2Mo-0.1Si. Metall Trans 14A:2363–2374

Ma F, Weijie L, Qin J, Zhang D (2006) Microstructure evolution of near alpha titanium alloy (Ti-1100 with TiC) during thermomechanical processing. Mater Sci Eng 416A:59–65

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Balasundar, I., Raghu, T. & Kashyap, B.P. Processing map for a cast and homogenized near alpha titanium alloy. Int J Mater Form 8, 85–97 (2015). https://doi.org/10.1007/s12289-013-1150-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-013-1150-y