Abstract

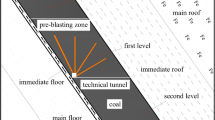

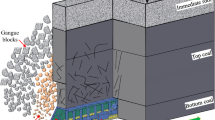

Steep coal seam mining activities will frequently occur during the next few decades in China. In this study, both experimental and numerical methods are employed to investigate the coal drawing from thick steep seam with longwall top coal caving mining. A series of analyses is performed to investigate the features of the drawing body, the distribution of top coal recovery ratio and the shape of the rock flow under steep conditions. The results indicate that the drawing body of top coal develops prior to upper side of the panel face obviously, and the top coal in the central part of the panel has a higher recovery ratio than that in the lower and upper parts in steep coal seam with caving mining method. The flow paths of the fragmented top coal are nearly straight lines moving towards the drawing window, and the fastest path maintains a constant angle with the plumb line. The spatial shape of the rock flow indicates “bidirectional asymmetry,” which results from the presence of the shield beam and dip angle of the coal seam; thus, this is the root cause of the appearance of the drawing body’s prior development towards the upper side of the panel. The field observation data indicates the same distribution of top coal recovery as that in the physical experiment and numerical simulation. Furthermore, suggested measurements are proposed to improve top coal recovery in steep seam mining based on the engineering practice of Dayuan coal mine.

Similar content being viewed by others

References

Alehossein H, Poulsen BA (2010) Stress analysis of longwall top coal caving. Int J Rock Mech Min Sci 47(1):30–41. https://doi.org/10.1016/j.ijrmms.2009.07.004

Blan ZF, Miao XX, Lei SG, Chen SE, Wang WF, Struthers S (2012) The challenges of reusing mining and mineral-processing wastes. Science 337(6095):702–703

Deng YH, Wang SQ (2014) Feasibility analysis of gob-side entry retaining on a working face in a steep coal seam. Int J Min Sci Tech 24(4):499–503. https://doi.org/10.1016/j.ijmst.2014.05.013

Ghosh AK, Gong Y (2014) Improving coal recovery from longwall top coal caving. J Mines Met Fuels 62(3):51–57

He MC, Peng YY, Zhao SY, Shi HY, Wang N, Gong WL (2015) Fracture mechanism of inversed trapezoidal shaped tunnel excavated in 45° inclined rock strata. Int J Min Sci Tech 25(4):531–535. https://doi.org/10.1016/j.ijmst.2015.05.003

Huang ZZ, Ren YF, Zhang HJ (2010) Study on key technology of fully mechanized top coal caving in extra-thick soft coal seam with great dip angle. J China Coal Soc 35(11):1878–1882

Huang BX, Zhao XL, Zhang Q (2016) Framework of the theory and technology for simultaneous mining of coal and its associated resources. J China Univ Min Tech 45(4):653–662

Klishin SV, Klishin VI (2009) Analysis of coal drawing from high coals in sublevel caving systems. Proceedings of ISRM Regional Symposium-EUROCK 2009. 29–31 October, 2009. International Society for Rock Mechanics. Cavtat 651-656

Klishin VI, Klishin SV (2010) Coal extraction from thick flat and steep beds. J Min Sci 46(2):149–159. https://doi.org/10.1007/s10913-010-0020-y

Klishin SV, Klishin VI, Opruk GY (2013) Modeling coal discharge in mechanized steep and thick coal mining. J Min Sci 49(6):932–940. https://doi.org/10.1134/S1062739149060130

Kumar R, Mishra AK, Singh AK, Singh AK, Ram S, Singh R (2016) Depillaring of total thickness of a thick coal seam in single lift using cable bolts: a case study. Int J Min Sci Tech 26(2):223–233. https://doi.org/10.1016/j.ijmst.2015.12.007

Kumar R, Singh AK, Mishra AK, Singh R (2015) Underground mining of thick coal seams. Int J Min Sci Tech 25(6):885–896. https://doi.org/10.1016/j.ijmst.2015.09.003

Li Q, Hou J, Han T, Liu H, Wang SJ (2016) Failure characteristics and support techniques of surrounding rock for deep rectangular roadway in Yangzhuang mine. J China Univ Min Tech 45(6):1124–1131

Miao SJ, Lai XP, Cui F (2011) Top coal flows in an excavation disturbed zone of high section top coal caving of an extremely steep and thick seam. Min Sci Tech (China) 21(1):99–105

Vakili A, Hebblewhite BK (2010) A new cavability assessment criterion for longwall top coal caving. Int J Rock Mech Min Sci 47(8):1317–1329. https://doi.org/10.1016/j.ijrmms.2010.08.010

Wang JH (2014) Development and prospect on fully mechanized mining in Chinese coal mines. Int J Min Sci Tech 1(3):253–260

Wang JC, Fu Q (2002) The loose medium flow field theory and its application on the longwall top-coal caving. J China Coal Soc 27(4):337–341

Wang JC, Li ZG, Chen YJ, Zheng HF (2004) The experimental study of loose medium flow field on the longwall top coal caving. J China Coal Soc 29(3):260–263

Wang JC, Yang SL, Li Y, Wei LK, Liu HH (2014) Caving mechanisms of loose top coal in longwall top coal caving mining method. Int J Rock Mech Min Sci 71(10):160–170. https://doi.org/10.1016/j.ijrmms.2014.04.024

Wang SR, Wang JA, Liu SH, Wu SC, Xie JW (2006) Particle flow analysis on mechanized top coal caving in steep thick seam. J Univ Sci Tech Beijing 28(9):808–811

Wang JC, Song ZY, Zhang JW, Chen Y (2016a) Theoretical model of drawing body in LTCC mining. J China Coal Soc 41(2):352–358

Wang ZQ, Zhao JL, Li ZQ (2013) Determination of height of “three zone” in the stope with stagger position and internal misaligned roadway layout. J Min Safety Eng 30(2):231–236

Wang JC, Yang JL, Liu HH, Zhao DP, Zheng LY (2010) The practical observation research on loose medium flow field theory on the top coal caving. J China Coal Soc 35(3):353–356

Wang JC, Zhang JW, Li Y (2015a) Ground control in China’s coal mine: progress and prospects. Proceedings of 48th US Rock Mechanics/Geomechanics Symposium. San Francisco, California, U.S., 28 June-1 July 2015. American Rock Mechanics Association, Virginia 1830-1835

Wang JC, Zhang JW, Song ZY, Li ZL (2015b) Three-dimensional experimental study of loose top coal drawing law for longwall top coal caving mining technology. J Rock Mech Geotech Eng 7(3):318–326. https://doi.org/10.1016/j.jrmge.2015.03.010

Wang JC, Zhang JW (2015) BBR study of top coal drawing law in longwall top coal caving mining. J China Coal Soc 40(3):487–493

Wang JC, Zhang JW, Li ZL (2016b) A new research system for caving mechanism analysis and its application to sublevel top coal caving mining. Int J Rock Mech Min Sci 88(10):273–285. https://doi.org/10.1016/j.ijrmms.2016.07.032

Yun DF, Liu Z, Cheng WD, Fan ZD, Wang DF, Zhang YH (2017) Monitoring strata behavior due to multi-slicing top coal caving longwall mining in steeply dipping extra thick coal seam. Int J Min Sci Tech 27(1):179–184. https://doi.org/10.1016/j.ijmst.2016.11.002

Yin GZ, Xian XF, Dai GF, Zhang DM (2001) Basic behaviour of strata movement in seam with deep dip angle. Chin. J Geotech Eng 23(4):450–453

Yang SL, Zhang JW, Chen Y, Song ZY (2016) Effect of upward angle on the drawing mechanism in longwall top coal caving mining. Int J Rock Mech Min Sci 85(5):92–101. https://doi.org/10.1016/j.ijrmms.2016.03.004

Zhang B, Cao SG (2015) Study on first caving fracture mechanism of overlying roof rock in steep thick coal seam. Int J Min Sci Tech 25(1):133–138. https://doi.org/10.1016/j.ijmst.2014.11.013

Zhang JW, Pan WD, Li ZL, Song ZY (2015) Development and application of 3D simulation test device for loose top coal drawing under caving mining technique. Chin J Rock Mech Eng 34(s2):3871–3879

Acknowledgements

The authors would like to thank the management of the Dayuan coal mine for their valuable cooperation during the reported field observation.

Funding

This research was funded by the National Natural Science Foundation of China (No. U1361209, No. 51674264 and No. 51574244) and the National Basic Research Program of China (No. 2013CB227903).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Jw., Wang, Jc., Wei, Wj. et al. Experimental and numerical investigation on coal drawing from thick steep seam with longwall top coal caving mining. Arab J Geosci 11, 96 (2018). https://doi.org/10.1007/s12517-018-3421-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-018-3421-x