Abstract

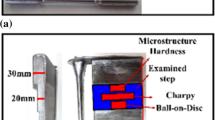

Although the manner in which the molten metal flows plays a major role in the formation of the uniform cylinder in centrifugal casting, not much information is available on this topic. The flow in the molten metal differs at various rotational speeds, which in turn affects the final casting. In this paper, the influence of the flow of molten metal of hyper eutectic Al-2Si alloys at various rotational speeds is discussed. At an optimum speed of 800 rpm, a uniform cylinder was formed. For the rotational speeds below and above these speeds, an irregular shaped casting was formed, which is mainly due to the influence of melt. Primary á-Al particles were formed in the tube periphery at low rotational speed, and their sizes and shapes were altered with changes in rotational speeds. The wear test for the inner surface of the casting showed better wear properties for the casting prepared at the optimum speed of rotation.

Similar content being viewed by others

References

Y. Jaluria, J. Fluid. Eng.-T. ASME 123, 173 (2001).

N. Janco, Centrifugal Casting, American Foundrymen’s Society (1988).

W. S. Ping, L. D. Rong, G. J. Jie, L. C. Yun, and S. Y. Qing, Mater. Sci. Eng. A 426, 240 (2006).

S. R. Chang, ISIJ Int. 41, 738 (2001).

G. Bergeles and J. Anagnostopoulos, Metall. Mater. Trans. B 30B, 1095 (1999).

B. G. Thomas and R. M. McDavid, Metall. Mater. Trans. B 27B, 672 (1996).

H. Fredriksson and C. M. Raihle, Metall. Mater. Trans. B 25B, 123 (1994).

I. V. Samarasekara and J. K. Brimacombe, Can. Metall. Quart. 38, 347 (1999).

I. V. Samaraskera, J. K. Brimacombe, and R. Bommaraju, ISS Trans. 5, 71 (1984).

J. K. Brimacombe, I. V. Samarasekera, N. Walker, E. A. Paterson, and J. D. Young, Metall. Mater. Trans. B 22B, 861 (1991).

H. K. Moffatt, J. Mec. 16, 651 (1977).

H. Barrow, Current Papers in Aeronautical Research Council, p. 1–10, London Her Majesty’s Stationary Office (1969).

S. T. Thoroddsen and L. Mahadevan, Experiments in Fluids, p. 1–13, Springer-Verlag (1997).

S. K. Wilson, R. Hunt, and B. R. Duffy, Q. J. Mech. Appl Math. 55, 357 (2002).

F. Marques, A. H. Hirsa, and R. Miraghaie, J. Fluid. Mech. 502, 99 (2004).

R. A. Shailesh, P. G. Mukunda, and S. Rao Shrikantha, J. Appl. Fluid. Mech. 2, 39 (2009).

R. A. Shailesh, P. G. Mukunda, and S. Rao Shrikantha, AFI/TFI-2007, Commemoration of the 100th Anniversary of Tohoku University, Sendai, Miyagi, Japan (2007).

K. G. Basavakumar, P. G. Mukunda, and M. Chakraborty, J. Mater. Sci. 42, 7882 (2007).

T. Iida, The Physical Properties of Liquid Metal, Clarendon Press, Oxford (1988).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mukunda, P.G., Shailesh, R.A. & Rao, S.S. Influence of rotational speed of centrifugal casting process on appearance, microstructure, and sliding wear behaviour of Al-2Si cast alloy. Met. Mater. Int. 16, 137–143 (2010). https://doi.org/10.1007/s12540-010-0137-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-010-0137-1