Abstract

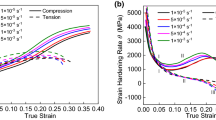

This paper is concerned with the effect of deformation twinning on the strain hardening behavior of commercially pure titanium during the compressive loading. In accordance with many studies on titanium, the strain hardening behavior of titanium during compression has different characteristics from those of general metallic materials. It has been reported that the strain hardening rate of titanium during compression can be divided into three stages. In the first stage, the strain hardening rate decreases as the strain increases due to dynamic recovery. Following the first stage, however, a sudden increase in the strain hardening rate is observed in the second stage. It is well known that the occurrence of the second stage is due to the generation of deformation twinning. After the second stage, the strain hardening rate decreases again as the strain increases in the third stage. In this paper, a strain hardening model that can represent the three stages of strain hardening is proposed based on the investigated effect of deformation twinning on the strain hardening behavior of titanium. The electron backscatter diffraction (EBSD) analyses are conducted to quantify the twin volume fraction with increase of compressive plastic strain, which provide fundamental frame of the hardening model for titanium.

Similar content being viewed by others

References

H. L. Kim and Y. W. Chang, Met. Mater. Int. 17, 563 (2011).

H. L. Kim and Y. W. Chang, Met. Mater. Int. 17, 721 (2011).

R. V. Mises, Z. Angew. Math. Mech. 8, 161 (1928).

G. I. Taylor, J. Inst. Met. 62, 307 (1938).

M. H. Yoo and C. T. Wei, J. Appl. Physi. 38, 4317 (1967).

M. H. Yoo, Metall. Trans. A 12, 409 (1981).

S. V. Kailas, Y. V. R. K. Prasad, and S. K. Biswas, Metall. Mater. Trans. A 25, 1425 (1994).

S. Nemat-Nasser, W. G. Guo, and J. Y. Cheng, Acta Mater. 47, 3705 (1999).

M. Doner and H. Conrad, Metall. Mater. Trans. B 4, 2809 (1973).

A. A. Salem, S. R. Kalidindi, and R. D. Doherty, Scripta Mater. 46, 419 (2002).

S. R. Kalidindi, A. A. Salem, and R. D. Doherty, Adv. Eng. Mater. 5, 229 (2003).

A. A. Salem, S. R. Kalidindi, and R. D. Doherty, Acta Mater. 51, 4225 (2003).

A. A. Salem, S. R. Kalidindi, and S. L. Semiatin, Acta Mater. 53, 3495 (2005).

A. A. Salem, S. R. Kalidindi, R. D. Doherty, and S. L. Semiatin, Metall. Mater. Trans. A 37, 259 (2006).

ASTM E9-89a, Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature (2000).

S. R. Agnew, M. H. Yoo, and C. N. Tomé, Acta Mater. 49, 4277 (2001).

G. Gilles, W. Hammami, V. Libertiaux, O. Cazacu, J. H. Yoon, T. Kuwabara, A. M. Habraken, and L. Duchêne, Int. J. Solids Struct. 48, 1277 (2011).

W. F. Hosford, The Mechanics of Crystals and Textured Polycrystals, pp.56–85, Oxford University Press, New York (1993).

U. F. Kocks, C. N. Tomé, and H.-R. Wenk, Texture and Anisotropy, pp.326–389, Cambridge University Press, Cambridge (1998).

B. Y. Jeong, Korean J. Met. Mater. 50, 867 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahn, K., Huh, H. & Yoon, J. Strain hardening model of pure titanium considering effects of deformation twinning. Met. Mater. Int. 19, 749–758 (2013). https://doi.org/10.1007/s12540-013-4014-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-013-4014-6