Abstract

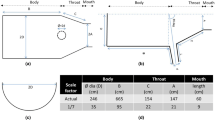

During tapping liquid steel from a converter to a ladle, slag may carry over due to a formation of free surface vortex. Such vortex should be suppressed in order to minimize contamination of the steel by slag. In the present study, a new idea is proposed to minimize the vortex formation by applying dual tapping hole system. The idea was tested using a rectangular shape water vessel with dual tapping holes, supplemented by a numerical simulations, in order to evaluate feasibility of the dual tapping hole system. Both the water model experiment and the numerical simulation showed similar tendencies that the dual tapping hole system is promising to prevent the vortex formation. Experimental results showed that the free surface vortex formation is highly sensitive to shape and configuration of the nozzle. From the numerical simulation, flow characteristics were obtained, and vortex canceling between two nozzles is confirmed. Effect of dual tapping hole increased with increasing distance between two holes in the present experimental condition. Finally, a 1/7.8 scale-down water vessel simulating a real converter was employed in order to confirm the validity of the above findings. The result showed almost the same tendencies with the previous findings.

Similar content being viewed by others

References

R. Sankaranarayanan and R. I. L. Guthrie, Ironmak. Steelmak. 29, 147 (2002).

K. Wunnenberg, Rev. Metall. 10, 687 (2005).

K. Kuwana, M. I. Hassan, P. K. Singh, K. Saito, and J. Nakagawa, Mater. Manuf. Process. 23, 407 (2008).

M. Piva, M. Iglesias, P. Bissio, and A. Calvo, Physica A 329, 1 (2003).

S. Mazumdar, N. Pradhan, P. K. Bhor, and K. Jaganathan, ISIJ Int. 35, 92 (1995).

G. M. Mazzaferro, M. Piva, S. P. Ferro, P. Bissio, M. Iglesias, A. Calvo, and M. B. Goldschmit, Ironmak. Steelmak. 31, 503 (2004).

S. Pirker, M. Lenchner, and G. Ernst, Int. J. Cast Metals Research. 22, 1 (2009).

H. Li, H. Chen, Z. Ma, and Y. Zhou, J. Hydrodyn. 21, 238 (2009).

Y. Chen, C. Wu, M. Ye, and X. Xu, J. Hydrodyn. 19, 143 (2007).

H. Li, H. Chen, Z. Ma, and Y. Zhou, J. Hydrodyn. 20, 485 (2008).

C. W. Hirt and B. D. Nichols, J. Comp. Phys. 39, 201 (1981).

FLUENT 12.0 Theory Guide, Ansys Inc. Canonsburg, PA (2009).

E.-Y. Ko, J. Choi, J.-Y. Park, and I. Sohn, Met. Mater. Int. 20, 141 (2014).

M. G. Jeong, C. Y. Choi, M. Y. Ha, S. J. Kim, J. K. Park, and K. S. Oh, Met. Mater. Int. 21, 303 (2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, SJ., Kim, SJ. & Lee, HG. New idea of suppressing free surface vortex during tapping liquid steel from converter. Met. Mater. Int. 22, 136–142 (2016). https://doi.org/10.1007/s12540-015-5428-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-015-5428-0