Abstract

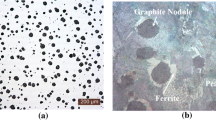

The aim of this investigation was to determine a procedure based on tensile testing to assess the critical range of austempering times for having the best ausferrite produced through austempering. The austempered ductile iron (ADI) 1050 was quenched at different times during austempering and the quenched samples were tested in tension. The dislocation-density-related constitutive equation proposed by Estrin for materials having high density of geometrical obstacles to dislocation motion, was used to model the flow curves of the tensile tested samples. On the basis of strain hardening theory, the equation parameters were related to the microstructure of the quenched samples and were used to assess the ADI microstructure evolution during austempering. The microstructure evolution was also analysed through conventional optical microscopy, electron back-scattered diffraction technique and transmission electron microscopy. The microstructure observations resulted to be consistent with the assessment based on tensile testing, so the dislocation-density-related constitutive equation was found to be a powerful tool to characterise the evolution of the solid state transformations of austempering.

Similar content being viewed by others

References

ASTM A897/A 897M-06, Standard Specification for Austempered Ductile Iron Castings, ASTM International, West Conshohocken, PA.

Y. J. Kim, H. Shin, H. Park, and J. Lim, Mater. Lett. 62, 357 (2008).

M. H. Sohi, M. N. Ahmadabadi, and A. B. Vahdat, J. Mater. Process. Tech. 153-154, 203 (2004).

J. L. Hernández-Rivera, R. E. Campos Cambranis, and A. de la Garza, Mater. Design 32, 4756 (2011).

S. Panneerselvam, C. J. Martis, S. K. Putatunda, and J. M. Boileau, Mat. Sci. Eng. A 626, 237 (2015).

A. Basso, J. Sikora, and R. Martinez, Fatigue Fract. Eng. M. 36, 650 (2013).

M. Soliman, A. Nofal, and H. Palkowski, Mater. Des. 87, 450 (2015).

D. O. Fernandino, J. M. Massone, and R. E. Boeri, J. Mater. Process. Tech. 213, 1801 (2013).

J. Yang and S. K. Putatunda, Mat. Sci. Eng. A 382, 265 (2004).

F. Zanardi, F. Bonollo, N. Bonora, A. Ruggiero, and G. Angella, Int. J. Metalcast. 11, 136 (2017).

A. Basso, R. Martínez, and J. Sikora, J. Alloy. Compd. 509, 9884 (2011).

J. Olofsson, D. Larsson, and I. L. Svensson, Metall. Mater. Trans. A 42, 3999 (2011).

A. Meena and M. El Mansori, Metall. Mater. Trans. A 43, 4755 (2012).

R. E. Smallman, I. R Harris, and M. A. Duggan, J. Mater. Process. Tech. 63, 18 (1997).

H. Fredriksson, J. Stjerndahl, and J. Tinoco, Mat. Sci. Eng. A 413, 363 (2005).

J. Dodd, Mod. Cast. 68, 60 (1978).

I. Schmidt and A. Schuchert, Z. Metallkd. 78, 871 (1987).

Zanardi Fonderie SpA, Internal report, http://zanardifonderie. com/en/(accessed February 19, 2014).

M. Kaczorowski and D. Myszka, Prace ITMat. SS, 10 (2003).

A. Krzynska and M. Kaczorowski, Arch. Foundry Eng. 7, 111 (2007).

R. E. Reed-Hill, W. R. Crebb, and S. N. Monteiro, Metall. Mater. Trans. A 4, 2665 (1973).

G. E. Dieter, Mechanical Metallurgy, p.286, McGraw-Hill Book Company Publisher, USA (1988).

H. J. Kleemola and M. A. Nieminen, Metall. Mater. Trans. A 5, 1863 (1974).

B. K. Choudhary, E. I. Samuel, K. B. S. Rao, and S. L. Mannan, Mater. Sci. Tech. 17, 223 (2001).

G. Angella, F. Zanardi, and R. Donnini, J. Alloy. Compd. 669, 262 (2016).

D. Hull and D. J. Bacon, Introduction to Dislocations, p.197, Butterworth-Heinemann Publisher, UK (2002).

R. W. K. Honeycombe and H. K. D. Bhadeshia, Steels - Microstructure and Properties, p.13, Butterworth- Heinemann Publisher, UK (1995).

U. F. Kocks, J. Eng. Mater-T. ASME 98, 76 (1976).

U. F. Kocks and H. Mecking, Acta Metall. 29, 1865 (1981).

U. F. Kocks and H. Mecking, Prog. Mater. Sci. 48, 171 (2003).

Y. Estrin, Dislocation Density Related Constitutive Modelling in: Unified Constitutive Laws of Plastic Deformation (eds. A. S. Krausz and K. Krausz), pp.66–106, Elsevier, Netherlands (1996).

Y. Estrin and H. Mecking, Acta Metall. 32, 57 (1984).

Y. Estrin, J. Mater. Process. Tech. 80-81, 33 (1998).

J. P. Sah, G. J. Richardson, and C. M. Sellars, J. Aus. Inst. Metals 14, 292 (1969).

G. Angella, D. Donnini, D. Ripamonti, and M. Maldini, Mat. Sci. Eng. A 594, 381 (2014).

H. J. Frost and M. F. Ashby, Deformation-Mechanism Maps, p. 32, Pergamon Press, UK (1982).

F. Y. Hung, L. H. Chen, and T. S. Lui, Mater. Trans. 45, 2981 (2004).

J. H. Jang, I. G. Kim, and H. K. D. H. Bhadeshia, Scripta Mater. 63, 121 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Donnini, R., Fabrizi, A., Bonollo, F. et al. Assessment of the microstructure evolution of an austempered ductile iron during austempering process through strain hardening analysis. Met. Mater. Int. 23, 855–864 (2017). https://doi.org/10.1007/s12540-017-6704-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-6704-y