Abstract

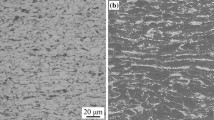

In this work, low carbon low alloy steel specimens were subjected to suitable heat treatment schedules to develop ferrite–pearlite (FP), ferrite–bainite (FB) and ferrite–martensite (FM) microstructures with nearly equal volume fraction of hard second phase or phase mixture. The role of pearlite, bainite and martensite on mechanical properties and flow behaviour were investigated through experiments and finite element simulations considering representative volume elements (RVE) based on real microstructures. For micromechanical simulation, dislocation based model was implemented to formulate the flow behaviour of individual phases. The optimum RVE size was identified for accurate estimation of stress–strain characteristics of all three duplex microstructures. Both experimental and simulation results established that FM structure exhibited superior strength and FP structure demonstrated better elongation while FB structure yielded moderate strength and ductility. The von Mises stress and plastic strain distribution of the individual phase was predicted at different stages of deformation and subsequent statistical analyses indicated that hard phases experienced maximum stress whereas, maximum straining occurred in soft ferrite phase for all three structures. Micromechanical simulation further revealed that strain accumulation occurred at the F–P and F–B interfaces while the same was observed within the martensite particles apart from the F–M interfaces for FM. These observations were further substantiated through the identification of void and crack initiation sites via subsurface examinations of failed tensile specimens.

Graphical abstract

Similar content being viewed by others

Change history

03 April 2021

The missed Graphic Abstract has been included.

References

G.R. Speich, R.L. Miller, Struct. Prop. Dual-Phase Steels 1, 424 (1979)

M. Sarwar, R. Priestner, J. Mater. Sci. 31, 2091 (1996)

E. Ahmad, R. Priestner, J. Mater. Eng. Perform. 7, 772 (1998)

M. Habibi, R. Hashemi, E. Sadeghi, A. Fazaeli, A. Ghazanfari, H. Lashini, J. Mater. Eng. Perform. 25, 382 (2016)

G. Krauss, S.W. Thompson, ISI J Int. 35, 937 (1995)

T. Gladman, I.D. McIvor, F.B. Pickering, J. Iron Steel Inst. 210, 916 (1970)

C.M. Bae, C.S. Lee, W.J. Nam, Mater. Sci. Technol. 18, 1317 (2003)

S. Kumar, A. Kumar, Vinaya, R. Madhusudhan, R. Sah, S. Manjini, J. Mater. Eng. Perform. 28, 3596 (2019)

I.S. Kim, U. Reichel, W. Dahl, Steel Res. 58, 186 (1987)

A. Fallahi, J. Mater. Sci. Technol. 18, 451 (2002)

D.L. Bourell, A. Rizk, Acta Metall. 31, 609 (1983)

C.N. Lanzillotto, F.B. Pickering, Met. Sci. 16, 371 (1982)

R.-M. Rodriguez, I. Gutiérrez, Mater. Sci. Forum 426–432, 4525 (2003)

S.K. Paul, Comput. Mater. Sci. 56, 34 (2012)

V. Uthaisangsuk, U. Prahl, W. Bleck, Eng. Fract. Mech. 78, 469 (2011)

S.K. Paul, Mater. Des. 44, 397 (2013)

A. Fallahi Arezodar, A. Nikbakht, J. Mater. Eng. Perform. 28, 53 (2019)

F.M. Al-Abbasi, J.A. Nemes, Int. J. Solids Struct. 45, 1449 (2003)

N. Ishikawa, D.M. Parks, S. Socrate, M. Kurihara, ISIJ Int. 40, 1170 (2000)

B. Anbarlooie, H. Hosseini-Toudeshky, M. Hosseini, J. Kadkhodapour, J. Mater. Eng. Perform. 28, 2903 (2019)

X. Sun, K.S. Choi, W.N. Liu, M.A. Khaleel, Int. J. Plast 25, 1888 (2009)

S.A. Asgari, P.D. Hodgson, C. Yang, B.F. Rolfe, Comput. Mater. Sci. 45, 860 (2009)

M. Marvi-Mashhadi, M. Mazinani, A. Rezaee-Bazzaz, Comput. Mater. Sci. 65, 197 (2012)

A. Ramazani, K. Mukherjee, U. Prahl, W. Bleck, Comput. Mater. Sci. 52, 46 (2012)

S.K. Basantia, V. Singh, A. Bhattacharya, N. Khutia, D. Das, Mater. Today Proc. 5, 18275 (2018)

H.K.D.H. Bhadeshia, Met. Sci. 16, 159 (1982)

ASTM, E8–99. “Standard Test Methods for Tension Testing of Metallic Materials.” Annual Book of ASTM Standards. ASTM (2001). (2001)

M. Amirmaleki, J. Samei, D.E. Green, I. van Riemsdijk, L. Stewart, Mech. Mater. 101, 27 (2016)

F.M. Al-Abbasi, J.A. Nemes, Comput. Mater. Sci. 39, 402 (2007)

S. Sodjit, V. Uthaisangsuk, Mater. Des. 41, 370 (2012)

J. Zhou, A.M. Gokhale, A. Gurumurthy, S.P. Bhat, Mater. Sci. Eng. A 630, 107 (2015)

K.S. Cheong, E.P. Busso, A. Arsenlis, Int. J. Plast 21, 1797 (2005)

A. Ramazani, K. Mukherjee, H. Quade, U. Prahl, W. Bleck, Mater. Sci. Eng. A 560, 129 (2013)

Y. Hou, T. Sapanathan, A. Dumon, P. Culière, M. Rachik, Comput. Mater. Sci. 123, 188 (2016)

D.D. Tjahjanto, S. Turteltaub, A.S.J. Suiker, S. Van Der Zwaag, Model. Simul. Mater. Sci. Eng. 14, 617 (2006)

N. Jia, Z.H. Cong, X. Sun, S. Cheng, Z.H. Nie, Y. Ren, P.K. Liaw, Y.D. Wang, Acta Mater. 57, 3965 (2009)

H. Ghassemi-Armaki, R. Maaß, S.P. Bhat, S. Sriram, J.R. Greer, K.S. Kumar, Acta Mater. 62, 197 (2014)

O. Bouaziz, P. B. Irsid, U. Group, G. Usinor, Int. J. Metall. 99, 71 (2002)

P. Srithananan, P. Kaewtatip, V. Uthaisangsuk, Mater. Sci. Eng. A 667, 61 (2016)

A. Ramazani, M. Abbasi, S. Kazemiabnavi, S. Schmauder, R. Larson, U. Prahl, Mater. Sci. Eng. A 660, 181 (2016)

R. Bakhtiari, A. Ekrami, Mater. Sci. Eng. A 525, 159 (2009)

M. Mazinani, W.J. Poole, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 38, 328 (2007)

D. Das, P.P. Chattopadhyay, J. Mater. Sci. 44, 2957 (2009)

P. Movahed, S. Kolahgar, S.P.H. Marashi, M. Pouranvari, N. Parvin, Mater. Sci. Eng. A 518, 1 (2009)

N.H. Abid, R.K. Abu Al-Rub, A.N. Palazotto, Comput. Mater. Sci. 103, 20 (2015)

L. Madej, J. Wang, K. Perzynski, P.D. Hodgson, Comput. Mater. Sci. 95, 651 (2014)

H. Hosseini-Toudeshky, B. Anbarlooie, J. Kadkhodapour, G. Shadalooyi, Mater. Sci. Eng. A 600, 108 (2014)

K.S. Choi, W.N. Liu, X. Sun, M.A. Khaleel, Acta Mater. 57, 2592 (2009)

M. Azuma, S. Goutianos, N. Hansen, G. Winther, X. Huang, Mater. Sci. Technol. 28, 1092 (2012)

Z.T. Zhao, X.S. Wang, G.Y. Qiao, S.Y. Zhang, B. Liao, F.R. Xiao, Mater. Des. 180, 107870 (2019)

Acknowledgements

The assistance received from the Centre of Excellence on Microstructurally Designed Advanced Materials Development, TEQIP-III of Indian Institute of Engineering Science and Technology (IIEST), Shibpur to carry out a part of this work is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Basantia, S.K., Bhattacharya, A., Khutia, N. et al. Plastic Behavior of Ferrite–Pearlite, Ferrite–Bainite and Ferrite–Martensite Steels: Experiments and Micromechanical Modelling. Met. Mater. Int. 27, 1025–1043 (2021). https://doi.org/10.1007/s12540-019-00519-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00519-5