Abstract

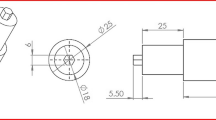

The present work studies the influence of five-pass overlapping friction stir processing (FSP) on microstructure, mechanical properties and corrosion behavior of AA6061 alloy. The fine equiaxed grains were produced in large-area stir region of overlapping FSP and it was identified that the grain size of each overlapping pass is uniform in large area stir region (average grain size = 3.9 ± 3.5 µm). The five-pass overlapping FSP resulted in ductility enhancement while the strength remained inferior to that of parent metal due to thermal softening during FSP. On the other hand, corrosion resistance greatly improved after FSP due to the formation of a homogenous fine-grained structure and discontinuous precipitates.

Graphic Abstract

Similar content being viewed by others

References

M.S. Weglowski, Friction stir processing—state of the art. Arch. Civ. Mech. Eng. 18, 114–129 (2018)

R.S. Mishra, Z.Y. Ma, Friction stir welding and processing. Mater. Sci. Eng. R 50, 1–78 (2005)

R. Nandan, T. Debroy, H.K.D.H. Bhadeshia, Recent advances in friction-stir welding-processing, weldment structure and properties. Prog. Mater Sci. 53, 980–1023 (2008)

M. Ebrahimi, M.A. Par, Twenty-year uninterrupted endeavour of friction stir processing by focusing on copper and its alloys. J. Alloys Compd. 781, 1074–1090 (2019)

I. Charith, R.S. Mishra, Effect of friction stir processed microstructure on tensile properties of an Al-Zn-Mg-Si alloy upon subsequent ageing treatment. Mater. Sci. Technol. 34, 214–218 (2018)

H.L. Zhao, Q. Pan, Q. Qin, Y. Wu, X. Su, Effect of the processing parameters on the microstructure and mechanical properties of 6063 Al alloy. Mater. Sci. Eng. A 751, 70–79 (2019)

Y. Chen, H. Ding, L. Jizhong, Z.-H. Cai, W. Yang, Influence of multipass friction stir processing on microstructure and mechanical properties of Al5083 alloy. Mater. Sci. Eng. A 650, 281–289 (2016)

K.J. Al-Fadhalaa, A.I. Almazrouee, A.S. Alorai, Microstructure and mechanical properties of multi-pass friction stir processed aluminium alloy 6063. Mater. Des. 53, 550–560 (2014)

M.K. Mishra, A.G. Rao, I. Balasundar, B.P. Kashyap, N. Prabhu, On the microstructure evolution in friction stir processed 2507 super duplex stainless steel and its effect on tensile behavior at ambient and elevated temperatures. Mater. Sci. Eng. A 719, 82–92 (2018)

I. Charit, R.S. Mishra, High strain rate superplasticity in a commercial 2024 Al alloy via friction stir processing. Mater. Sci. Eng. A 359, 290–296 (2003)

F. Nascimento, T. Santos, P. Vilaca, R.M. Miranda, L. Quintino, Microstructural modification and ductility enhancement of surfaces modified by FSP in aluminium alloys. Mater. Sci. Eng., A 506, 16–22 (2009)

P. Xue, B.L. Xiao, Z.Y. Ma, achieving large-area bulk ultrafine-grained Cu via submerged multi-pass friction stir processing. Journal of Material Science and Technology 29, 1111–1115 (2013)

K.N. Ramesh, S. Pradeep, V. Pancholi, Multipass friction-stir processing and its effect on mechanical properties of aluminum alloy 5086. The Minerals, Metallurgical and Materials Society Transactions A 43A, 4311–4319 (2012)

J.-Q. Su, T.W. Nelson, C.J. Sterling, Friction stir processing of large-area bulk UFG aluminium alloys. Scripta Mater. 52, 135–140 (2005)

L.B. Johannes, R.S. Mishra, Multiple passes of friction stir processing for the creation of superplastic 7075 aluminium. Mater. Sci. Eng., A 464, 255–260 (2007)

J. Gandra, R.M. Miranda, P. Vilaca, Effect of overlapping direction in multipass friction stir processing. Mater. Sci. Eng., A 528, 5592–5599 (2011)

G. Venkateswarlu, D. Devaraju, M.J. Davidson, B. Kotiveerachari, G.R.N. Tagore, Effect of overlapping ratio on mechanical properties and formability of friction stir processed Mg AZ31B alloy. Mater. Des. 43, 480–486 (2013)

A. Alavi-Ni, H. Omidvar, S.H. Nourbakhsh, Effects of an overlapping multi-pass friction stir process and rapid cooling on the mechanical properties and microstructure of AZ31magnesium alloy. Mater. Des. 58, 298–304 (2014)

K. Nakata, Y.G. Kim, H. Fujii, T. Tsumura, T. Komazaki, Improvement of mechanical properties of aluminum die casting alloy by multi-pass friction stir processing. Mater. Sci. Eng., A 437, 274–280 (2006)

A. Dutta, I. Charit, L.B. Johannes, R.S. Mishra, Deep cup forming by superplastic punch stretching of friction stir processed 7075 Al alloy. Mater. Sci. Eng., A 395, 173–179 (2005)

Y.J. Kwon, I. Shigematsu, N. Saito, Mechanical properties of fine-grained aluminum alloy produced by friction stir process. Scripta Mater. 49, 785–789 (2003)

Y.S. Sato, S.H.C. Park, A. Matsunga, A. Honda, H. Kokawa, Novel production for highly formable Mg alloy plate. J. Mater. Sci. 40, 637–642 (2005)

K.J. Al-Fadhalah, A.I. Almazrouee, A.S. Aloraier, Microstructure and mechanical properties of multi-pass friction stir processed aluminum alloy 6063. Mater. Des. 53, 550–560 (2014)

C.-Y. Choua, C.-W. Hsua, S.-L. Leeb, K.-W. Wangc, J.-C. Linb, Effects of heat treatments on AA6061 aluminium alloy deformed by cross-channel extrusion. J. Mater. Process. Technol. 202, 1–6 (2008)

C.Y. Liu, B. Qu, P. Xue, Z.Y. Ma, K. Luo, M.Z. Ma, R.P. Liu, Fabrication of large-bulk ultrafine-grained 6061 aluminium alloy by rolling and low-heat-input friction stir welding. J. Mater. Sci. Technol. 34, 112–118 (2018)

K. Elangovan, V. Balasubramanian, Influence of tool pin profile and welding speed on the formation of friction stir processing zone in AA2219 aluminium alloy. Journal of Material Processing and Technology 200, 163–175 (2008)

K. Elangovan, V. Balasubramanian, Influence of tool pin profile and tool shoulder diameter on the formation of friction stir processing zone in AA6061 aluminium alloy. Mater. Des. 28, 362–373 (2008)

D. Ghanbari, M.K. Asgarani, K. Amini, F. Gharavi, Influence of heat treatment on mechanical properties and microstructure of the AA2024/SiC composite produced by multi-pass friction stir processing. Measurement 104, 151–158 (2017)

W. Xu, J. Liu, Microstructure and pitting corrosion of friction stir welded joints in 2219-O aluminium alloy thick plate. Corros. Sci. 51, 2743–2751 (2009)

W. Xu, J. Liu, G. Luan, C. Dong, Microstructure and mechanical properties of friction stir welded joints in 2219–T6 aluminum alloy. Mater. Des. 30, 3460–3467 (2009)

Y. Zhao, Q. Wang, H. Chen, K. Yan, Microstructure and mechanical properties of spray formed 7055 aluminium alloy by underwater friction stir welding. Mater. Des. 56, 725–730 (2014)

I.J. Polmear, Light Alloys (BH Publications, Oxford, 2006)

F. Gharavi, K.A. Matori, R. Yunus, N.K. Othman, F. Fadaeifard, Corrosion behavior of friction stir welded lap joints of AA6061-T6 aluminium alloy. Mater. Res. 17, 672–681 (2014)

S. Sinhmar, D.K. Dwivedi, Enhancement of mechanical properties and corrosion resistance of friction stir welded joint of AA2014 using water cooling. Mater. Sci. Eng. A 684, 413–422 (2017)

D. Dua, R. Fu, Y. Li, L. Jing, J. Wang, Y. Ren, K. Yang, Modification of the Hall-Petch equation for friction-stir-processing microstructures of high-nitrogen steel. Mater. Sci. Eng. A 640, 190–194 (2015)

H. Zhao, Q. Pan, Q. Qin, Y. Wu, X. Su, Effect of the processing parameters of friction stir processing on the microstructure and mechanical properties of 6063 aluminum alloy. Mater. Sci. Eng. A 751, 70–79 (2019)

S.M. Li, Y.D. Li, Y. Zhang, J.H. Liu, M. Yu, Effect of intermetallic phases on anodic oxidation and corrosion resistance of 5A06 aluminum alloy. Int. J. Miner. Metall. Mater. 22, 167–174 (2015)

H.-L. Qin, H. Zhang, D. Sun, Q. Zhuang, Corrosion behavior of the friction-stir-welded joints of 2A14-T6 aluminium alloy. Int. J. Miner. Metall. Mater. 22, 627–638 (2015)

S. Sinhmar, D.K. Dwivedi, Effect of weld thermal cycle on metallurgical and corrosion behavior of friction stir weld joint of AA2014 aluminium alloy. J. Manuf. Process 37, 305–320 (2019)

Acknowledgements

The authors gratefully thank the financial support provided by AR&DB (DRDO), New Delhi through the Grant CCMT/TM/ARDB/GIA/16-17/0332 dated 17/01/2017. The authors also thank Dr. Ch. Raja Mohan, Assistant Professor, Chemical Engineering Department for providing facilities for corrosion testing.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Satyanarayana, M.V.N.V., Adepu, K. & Chauhan, K. Effect of Overlapping Friction Stir Processing on Microstructure, Mechanical Properties and Corrosion Behavior of AA6061 Alloy. Met. Mater. Int. 27, 3563–3573 (2021). https://doi.org/10.1007/s12540-020-00757-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00757-y