Abstract

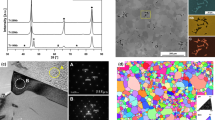

In this study, we synthesized a new Al16.6Cu16.6Fe16.6Mn16.6Mg16.6Ti16.6 lightweight high entropy alloy (LWHEA) by high energy ball milling and spark plasma sintering (SPS). The effect of milling time (15, 30, 45, and 60 h) and SPS conditions (600 and 700 °C) on microstructure, hardness, and density of LWHEAs were studied. The results showed that milled LWHEA is base centered cubic (BCC) structured, consisting of dual BCC1/BCC2 matrix with dispersed minor Cu2Mg precipitates and Ti. After SPS of milled samples, the BCC2 phase fraction was increased gradually. The distribution of Ti was uniform up to 45 h milled sample SPSed at 600 °C. However, porosity was built up beyond 45 h milling and higher SPS temperature (700 °C). The presence of finer secondary phases in the HEA matrix contributes to the dispersion hardening. The optimum microhardness and density of LWHEA AlCuFeMnMgTi were around 770 HV and 4.34 g cm− 3 which is superior to other conventional alloys such as Al or Ti-based alloys.

Graphic Abstract

Similar content being viewed by others

References

B.S. Murty, J.W. Yeh, S. Ranganathan, High-Entropy Alloys, 1st edn. (Elsevier, Butterworth-Heinemann, 2014), pp. 1–218

B. Cantor, I.T.H. Chang, P. Knight, A.J.B. Vincent, Mater. Sci. Eng. A 375–377, 213 (2004)

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004)

B. Cantor, Entropy 16, 4749 (2014)

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, Z.P. Lu, Prog. Mater. Sci. 61, 1 (2014)

A. Kumar, M. Gupta, Metals 6(9), 199 (2016)

X. Huang, J. Miao, A.A. Luo, J. Mater. Sci. 54, 2271 (2019)

N.D. Stepanov, N.Y. Yurchenko, E.S. Panina, M.A. Tikhonovsky, S.V. Zherebtsov, Mater. Lett. 188, 162 (2017)

K.M. Youssef, A.J. Zaddach, C. Niu, D.L. Irving, C.C. Koch, Mater. Res. Lett. 3, 95 (2014)

K. Tseng, Y. Yang, C. Juan, T. Chin, C. Tsai, J. Yeh, Sci. China Technol. Sci. 61, 184 (2018)

L. Raman, K. Guruvidyathri, G. Kumari, S.V.S.N. Murty, R.S. Kottada, B.S. Murty, J. Mater. Res. 34, 756 (2019)

J.Y. He, H. Wang, H.L. Huang, X.D. Xu, M.W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An, Z.P. Lu, Acta Mater. 102, 187 (2016)

Y. Deng, C.C. Tasan, K.G. Pradeep, H. Springer, A. Kostka, D. Raabe, Acta Mater. 94, 124 (2015)

S.S. Nene, M. Frank, K. Liu, R.S. Mishra, B.A. McWilliams, K.C. Cho, Sci. Rep. 8, 9920 (2018)

Y. Zou, J.M. Wheeler, H. Ma, P. Okle, R. Spolenak, Nano Lett. 17, 1569 (2017)

J.M. Sanchez, I. Vicario, J. Albizuri, T. Guraya, E.M. Acuña, Sci. Rep. 9, 6792 (2019)

F. Lukáč, M. Dudr, J. Čížek, P. Harcuba, T. Vlasák, M. Janeček, J. Kuriplach, J. Moon, H.S. Kim, J. Zýka, J. Málek, Acta Phys. Pol. A 134, 891 (2018)

S. Mridha, S. Samal, P.Y. Khan, K. Biswas, Govind, Metall. Mater. Trans. A 44, 4532 (2013)

S. Nam, S.E. Shin, J.H. Kim, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00769-8

W. Wang, B. Li, S. Zhai, J. Xu, Z. Niu, J. Xu, Y. Wang, Met. Mater. Int. 24, 1112 (2018)

Y.A. Alshataif, S. Sivasankaran, F.A. Al-Mufadi, A.S. Alaboodi, H.R. Ammar, Met. Mater. Int. 26, 1099 (2020)

J.M. Torralba, P. Alvaredo, A.G. Junceda, Powder Metall. 62(2), 84 (2019)

L.M. Gouvea, I. Moravcik, M. Omasta, J. Veselý, J. Cizek, P. Minárik, J. Cupera, A. Záděra, V. Jan, I. Dlouhy, Mater. Charact. 159, 110046 (2020)

A.Y. Volkov, A.A. Kalonov, D.A. Komkova, A.V. Glukhov, Phys. Met. Metallogr. 119, 946 (2018)

Y.E. Lee, S.L. Houser, Essential Readings in Light Metals (Springer, Cham, 2016), pp. 44–50

S. Hori, H. Tai, E. Matsumoto, J. Jpn. Inst. Light Met. 34(7), 377 (1987)

J. Lin, M. Huang, W. Yang, L. Xing, Sci. Rep. 8, 15190 (2018)

Y. Song, M. Wang, Y. Zong, R. He, J. Jin, Materials 11, 1903 (2018)

M.D. Alcala, C. Real, I. Fombella, I. Trigo, J.M. Cordoba, J. Alloys Compd. 749, 834 (2018)

Y. Dong, Y. Lu, J. Kong, J. Zhang, T. Li, J. Alloys Compd. 573, 96 (2013)

Y.J. Zhou, Y. Zhang, Y.L. Wang, G.L. Chen, Appl. Phys. Lett. 90, 181904 (2007)

G.E. Dieter, Mechanical Metallurgy, SI Metric Edn (McGraw-Hill Book Company, London, 1988), pp. 282–295

C.C. Juan, J.W. Yeh, T.S. Chin, A novel light high-entropy alloy Al20Be20Fe10Si15Ti35, E-MRS Fall Meeting, Symposium I, Warsaw, Poland, (2009)

P. Chauhan, S. Yebaji, V.N. Nadakuduru, T. Shanmugasundaram, J. Alloys Compd. 820, 153367 (2020)

M. Zhang, W. Zhang, Y. Liu, B. Liu, J. Wang, Powder Met. 61(2), 123 (2018)

S. Praveen, B.S. Murty, R.S. Kottada, Mater. Sci. Eng. A 534, 83 (2012)

O. Maulik, D. Kumar, S. Kumar, D.M. Fabijanic, V. Kumar, Intermetalics 77, 46 (2016)

L.R. Kanyane, A.P.I. Popoola, N. Malatji, P.N. Sibisi, Mater. Today Proc. (2020). https://doi.org/10.1016/j.matpr.2020.02.095

B. Kang, J. Lee, H.J. Ryu, S.H. Hong, J. Alloys Compd. 767, 1012 (2018)

V.H. Hammond, M.A. Atwater, K.A. Darling, H.Q. Nguyen, L.J. Kecskes, JOM 66, 2021 (2014)

Acknowledgements

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2018R1D1A1B07044481).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chae, M.J., Sharma, A., Oh, M.C. et al. Lightweight AlCuFeMnMgTi High Entropy Alloy with High Strength-to-Density Ratio Processed by Powder Metallurgy. Met. Mater. Int. 27, 629–638 (2021). https://doi.org/10.1007/s12540-020-00823-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00823-5