Abstract

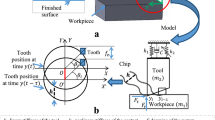

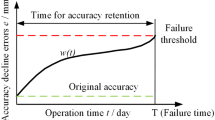

To maximize the potential for high material removal rates in simultaneous processes such as parallel milling, developing strategies for successful chatter suppression/avoidance is an important concern for manufacturers. In this study, the effectiveness of the spindle speed difference method (SDM) for chatter suppression is discussed in a parallel end-milling process where a flexible workpiece is machined by two tools rotating in opposite direction. The process model is developed, considering that the dynamic variation due to the regenerative effect occurs on a plane perpendicular to the tool axis direction. Through the process simulations and the experiments, this study provides informative discussion for comprehending the process behavior. Additionally, a real-time active chatter suppression system with adaptive SDM, where the spindle speed difference is sequentially optimized during the process according to the tracked chatter frequency, is developed by integrating a chatter monitoring system based on sensorless cutting force estimation with sliding discrete Fourier transform. The results show that the developed real-time adaptive system of spindle speed suppresses chatter vibrations more effectively than non-adaptive SDM system; hence, the integrated system can contribute self-optimizing machining systems oriented to Industry 4.0.

Similar content being viewed by others

Abbreviations

- a p :

-

Axial depth of cut

- a t :

-

Acceleration of table

- c f :

-

Feed per tooth

- \(dF_{t} , dF_{r} , dF_{a}\) :

-

Minute cutting force in tool tangential, radial, and axial directions

- \(dF_{\text{x}} , dF_{y} , dF_{z}\) :

-

Minute cutting force in Cartesian coordinate system

- F cut :

-

Cutting force

- F stat :

-

Non-process-related force including friction and gravity terms

- \(F_{x} , F_{y} , F_{z}\) :

-

Cutting force in Cartesian coordinate system

- g(θ):

-

Unit step function to judge tooth engagement

- G(iω):

-

Frequency response function

- G LPF(s):

-

Low-pass filter

- h :

-

Uncut chip thickness

- I ref a :

-

Motor current reference

- J r :

-

Total inertia of motor, coupling, and ball screw

- k c :

-

Chatter lobe number

- K t :

-

Torque coefficient

- \(K_{te} , K_{re} , K_{ae}\) :

-

Edge force coefficient in tangential, radial, and axial directions

- \(K_{tc} , K_{rc} , K_{ac}\) :

-

Cutting force coefficients in tangential, radial, and axial directions

- L :

-

Number of divisions along axial depth of cut

- M t :

-

Movable mass

- n :

-

Arbitrary integer

- R :

-

Transform coefficient for rotational motion to translational motion

- S :

-

Spindle speed

- T z :

-

Tooth-pass period (= 60/(ZS))

- T c :

-

Chatter vibration period (= 2π/ωc)

- Z :

-

Number of teeth

- α 0 :

-

Time-invariant average directional dynamic milling force coefficient

- α r :

-

Angular acceleration of motor

- Δa p :

-

Thickness of each minute disk element

- ΔT z :

-

Difference of tooth-pass period between two tools

- Δɛ :

-

Phase difference between tool 1 and 2

- ɛ :

-

Total phase shift between present and previous vibration before one tooth pass

- θ :

-

Rotation angle

- \(\lambda , \lambda_{R} , \lambda_{I}\) :

-

Eigenvalue of the characteristic force equation and its real and imaginary part (λ = λR + λI)

- ω c :

-

Chatter frequency

- \(_{j} , _{m}\) :

-

Value at j-th teeth and/or m-th minute disk

- \(_{n}\) :

-

Nominal value

- \(_{pq}\) :

-

Value from q to p direction (\(p, q = x, y, z\))

- \(^{{{\text{t}}1}} , ^{{{\text{t}}2}}\) :

-

Value for tool 1 or tool 2

- \(^{\text{w}}\) :

-

Value for workpiece

- \(\left( \wedge \right)\) :

-

Estimated value

References

Moriwaki, T. (2008). Multi-functional machine tool. CIRP Annals, 57(2), 736–749. https://doi.org/10.1016/j.cirp.2008.09.004.

Nakamoto, K., & Takeuchi, Y. (2017). Recent advances in multiaxis control and multitasking machining. International Journal of Automation Technology, 11(2), 140–154. https://doi.org/10.20965/ijat.2017.p0140.

Budak, E., & Ozturk, E. (2011). Dynamics and stability of parallel turning operations. CIRP Annals - Manufacturing Technology, 60(1), 383–386. https://doi.org/10.1016/j.cirp.2011.03.028.

Brecher, C., Epple, E., Neus, S., & Fey, S. (2015). Optimal process parameters for parallel turning operations on shared cutting surfaces. International Journal of Machine Tools and Manufacture, 95, 13–19. https://doi.org/10.1016/j.ijmachtools.2015.05.003.

Azvar, M., & Budak, E. (2017). Multi-dimensional chatter stability for enhanced productivity in different parallel turning strategies. International Journal of Machine Tools and Manufacture, 123, 116–128. https://doi.org/10.1016/j.ijmachtools.2017.08.005.

Reith, M. J., Bachrathy, D., & Stepan, G. (2016). Optimal detuning of a parallel turning system—theory and experiments. Journal of Dynamic Systems, Measurement, and Control, 139(1), 014503. https://doi.org/10.1115/1.4034497.

Brecher, C., Trofimov, Y., & Bäumler, S. (2011). Holistic modelling of process machine interactions in parallel milling. CIRP Annals - Manufacturing Technology, 60(1), 387–390. https://doi.org/10.1016/j.cirp.2011.03.025.

Budak, E., Comak, A., & Ozturk, E. (2013). Stability and high performance machining conditions in simultaneous milling. CIRP Annals - Manufacturing Technology, 62(1), 403–406. https://doi.org/10.1016/j.cirp.2013.03.141.

Yan, R., Tang, X., Peng, F. Y., Wang, Y., & Qiu, F. (2016). The effect of variable cutting depth and thickness on milling stability for orthogonal turn-milling. The International Journal of Advanced Manufacturing Technology, 82, 765–777. https://doi.org/10.1007/s00170-015-7418-2.

Sun, T., Qin, L., Fu, Y., & Hou, J. (2019). Chatter stability of orthogonal turn-milling analyzed by complete discretization method. Precision Engineering, 56, 87–95. https://doi.org/10.1016/j.precisioneng.2018.10.012.

Shamoto, E., Mori, T., Nishimura, K., Hiramatsu, T., & Kurata, Y. (2010). Suppression of regenerative chatter vibration in simultaneous double-sided milling of flexible plates by speed difference. CIRP Annals - Manufacturing Technology, 59(1), 387–390. https://doi.org/10.1016/j.cirp.2010.03.028.

Shamoto, E., Mori, T., Sencer, B., Suzuki, N., & Hino, R. (2013). Suppression of regenerative chatter vibration in multiple milling utilizing speed difference method – analysis of double-sided milling and its generalization to multiple milling operations. Precision Engineering, 37(3), 580–589. https://doi.org/10.1016/j.precisioneng.2013.01.003.

Hayasaka, T., Xu, Y., Jung, H., Shamoto, E., & Xu, L. (2019). Regenerative chatter by teeth allocated in the cutting direction with position-dependent modal displacement ratios. CIRP Annals - Manufacturing Technology, 68(1), 409–412. https://doi.org/10.1016/j.cirp.2019.04.003.

Yamato, S., Yamada, Y., Nakanishi, K., Suzuki, N., Yoshioka, H., & Kakinuma, Y. (2018). Integrated in-process chatter monitoring and automatic suppression with adaptive pitch control in parallel turning. Advances in Manufacturing, 6, 291–300. https://doi.org/10.1007/s40436-018-0222-0.

Yamato, S., Okuma, T., Nakanishi, K., Tachibana, J., Suzuki, N., & Kakinuma, Y. (2019). Chatter suppression in parallel turning assisted with tool swing motion provided by feed system. International Journal of Automation Technology, 13(1), 80–91. https://doi.org/10.20965/ijat.2019.p0080.

Bediaga, I., Muñoa, J., Hernández, J., & López de Lacalle, L. N. (2009). An automatic spindle speed selection strategy to obtain stability in high-speed milling. International Journal of Machine Tools and Manufacture, 49(5), 384–394. https://doi.org/10.1016/j.ijmachtools.2008.12.003.

Al-Regib, E., Ni, J., & Lee, S. H. (2003). Programming spindle speed variation for machine tool chatter suppression. International Journal of Machine Tools and Manufacture, 43(12), 1229–1240. https://doi.org/10.1016/S0890-6955(03)00126-3.

Möhring, H.-C., Wiederkehr, P., Erkorkmaz, K., & Kakinuma, Y. (2020). Self-optimizing machining systems. CIRP Annals - Manufacturing Technology, 69(2), 740–763. https://doi.org/10.1016/j.cirp.2020.05.007.

Budak, E., Altintas, Y., & Armarego, E. J. A. (1996). Prediction of milling force coefficients from orthogonal cutting data. Journal of Manufacturing Science and Engineering, 118(2), 216–224. https://doi.org/10.1115/1.2831014.

Yamada, Y., & Kakinuma, Y. (2016). Sensorless cutting force estimation for full-closed controlled ball-screw-driven stage. The International Journal of Advanced Manufacturing Technology, 87, 3337–3348. https://doi.org/10.1007/s00170-016-8710-5.

Yamada, Y., Kadota, T., Sakata, S., Tachibana, J., Nakanishi, K., Sawada, M., et al. (2017). Integrated chatter monitoring based on sensorless cutting force/torque estimation in parallel turning. International Journal of Automation Technology, 11(2), 215–225. https://doi.org/10.20965/ijat.2017.p0215.

Altintas, Y., & Budak, E. (1995). Analytical prediction of stability lobes in milling. CIRP Annals - Manufacturing Technology, 44(1), 357–362. https://doi.org/10.1016/S0007-8506(07)62342-7.

Hayasaka, T., Ito, A., & Shamoto, E. (2017). Generalized design method of highly-varied-helix end mills for suppression of regenerative chatter in peripheral milling. Precision Engineering, 48, 45–59. https://doi.org/10.1016/j.precisioneng.2016.11.004.

Tlusty, J., & Ismail, F. (1981). Basic Non-Linearity in Machining Chatter. CIRP Annals - Manufacturing Technology, 30(1), 299–304. https://doi.org/10.1016/S0007-8506(07)60946-9.

Aslan, D., & Altintas, Y. (2018). On-line chatter detection in milling using drive motor current commands extracted from CNC. International Journal of Machine Tools and Manufacture, 132, 64–80. https://doi.org/10.1016/j.ijmachtools.2018.04.007.

Zatarain, M., Bediaga, I., Muñoa, J., & Lizarralde, R. (2008). Stability of milling processes with continuous spindle speed variation: analysis in the frequency and time domains, and experimental correlation. CIRP Annals - Manufacturing Technology, 57(1), 379–384. https://doi.org/10.1016/j.cirp.2008.03.067.

Jacobsen, E., & Lyons, R. (2003). The sliding DFT. IEEE Signal Processing Magazine, 20(2), 74–80. https://doi.org/10.1109/MSP.2003.1184347.

Mori, T., Hiramatsu, T., & Shamoto, E. (2011). Simultaneous double-sided milling of flexible plates with high accuracy and high efficiency—Suppression of forced chatter vibration with synchronized single-tooth cutters. Precision Engineering, 35(3), 416–423. https://doi.org/10.1016/j.precisioneng.2011.02.002.

Acknowledgements

This work was partially supported by the SIP Innovative Design and Production Technology Project commissioned by the New Energy and Industrial Technology Development Organization (NEDO), JSPS Grant-in-Aid for Fellows Grant Numbers JP19J13204, and Keio University Doctoral Student Grant-in-Aid Program. The authors thank Mr. Okuma and the OMRON Corporation for their support and assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper was presented at ASPEN 2019.

Appendix

Appendix

Equation (10) can be rearranged as follows:

By solving the general eigenvalue problem of Eq. (17) and obtaining the eigenvalues, the critical axial depth of cut, ap(lim) can be derived similarly as in the conventional milling process, as follows:

The axial depth of cut term is included in the left-hand side of Eq. (17). Therefore, the eigenvalues were searched such that the initially set value of the axial depth of cut was equal to the value calculated using Eq. (18) while updating the initial value.

Rights and permissions

About this article

Cite this article

Yamato, S., Nakanishi, K., Suzuki, N. et al. Development of Automatic Chatter Suppression System in Parallel Milling by Real-Time Spindle Speed Control with Observer-Based Chatter Monitoring. Int. J. Precis. Eng. Manuf. 22, 227–240 (2021). https://doi.org/10.1007/s12541-021-00469-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-021-00469-2