Abstract

Industries across the world today are looking for cost effective solutions to reduce waste and curb the carbon emission, due to heightened awareness about ecological responsibility coupled with stringent government regulation and legislations, through operational adjustments in manufacturing/remanufacturing and collection (used products) policy. This paper presents a production, remanufacture and waste disposal EPQ model under different carbon regulatory mechanisms of a firm that sells new and repaired versions of its product at two different markets and it is assumed that remanufactured items are of poorer quality; i.e., not ’as-good-as new’. In reality, the return rates of used product from the end customers of both markets are influenced by the purchasing price, and therefore this study suggests that the return flow of used product as an increasing function of purchasing price. We studied the optimization model under two scenarios: (i) no carbon emission policy (ii) carbon emission norms (a. carbon tax; b. strict carbon cap; c. carbon cap and trade). Mathematical modeling followed by numerical analysis is carried out to examine the impact of regulatory policies on optimal decisions and overall emissions. The results indicate that remanufacturing is an effective strategy to decrease carbon emission compared to manufacturing process.

Similar content being viewed by others

References

Bazan, E., Jaber, M.Y., Zanoni, S.: Supply chain models with greenhouse gases emissions, energy usage and different coordination decisions. Appl. Math. Model. 39(17), 5131–5151 (2015)

Bazan, E., Jaber, M.Y., Zanoni, S.: Carbon emissions and energy effects on a two-level manufacturer-retailer closed-loop supply chain model with remanufacturing subject to different coordination mechanisms. Int. J. Prod. Econ. 183, 394–408 (2017)

Bonney, M., Jaber, M.Y.: Environmentally responsible inventory models: non-classical models for a non-classical era. Int. J. Prod. Econ. 133(1), 43–53 (2011)

Chaabane, A., Ramudhin, A., Paquet, M.: Design of sustainable supply chains under the emission trading scheme. Int. J. Prod. Econ. 135(1), 37–49 (2012)

Chung, S.L., Wee, H.M., Yang, P.C.: Optimal policy for a closed-loop supply chain inventory system with remanufacturing. Math. Comput. Modell. 48(5), 867–881 (2008)

Dobos, I., Richter, K.: A production/recycling model with stationary demand and return rates. CEJOR 11(1), 3546 (2003)

Dobos, I., Richter, K.: An extended production/recycling model with stationary demand and return rates. Int. J. Prod. Econ. 90(3), 311323 (2004)

Dobos, I., Richter, K.: A production/recycling model with quality consideration. Int. J. Prod. Econ. 104(2), 571–579 (2006)

Du, S., Zhu, L., Liang, L., Ma, F.: Emission-dependent supply chain and environment-policy-making in the ’cap-and-trade’system. Energy Policy 57, 61–67 (2013)

Economic survey 2014–2015: From Carbon Subsidy to Carbon Tax: India’s Green Actions. Economic survey Volume-1, Chapter-9. http://www.domain-b.com/economy/ecosurvey2015/pdf/volume_I/20150227_echapvol1-09.pdf (2015). Accessed 27 Feb 2015

Hovelaque, V., Bironneau, L.: The carbon-constrained EOQ model with carbon emission dependent demand. Int. J. Prod. Econ. 164, 285–291 (2015)

Jaber, M.Y., El Saadany, A.M.: The production, remanufacture and waste disposal model with lost sales. Int. J. Prod. Econ. 120(1), 115–124 (2009)

Jaber, M.Y., Glock, C.H., El Saadany, A.M.: Supply chain coordination with emissions reduction incentives. Int. J. Prod. Res. 51(1), 69–82 (2013)

Krikke, H.: Impact of closed-loop network configurations on carbon footprints: a case study in copiers. Resour. Conserv. Recycl. 55(12), 1196–1205 (2011)

Kundu, S., Chakrabarti, T., Jana, D.K.: Optimal manufacturing-remanufacturing production policy for a closed-loop supply chain under fill rate and budget constraint in Bifuzzy environments. Int. J. Math. Math. Sci. Article ID 690435 (2014)

Narita, H.: Environmental burden analyzer for machine tool operations and its application. INTECH Open Access Publisher (2012). http://cdn.intechopen.com/pdfs-wm/36413.pdf

Peng, Y., Ablanedo-Rosasb, J.H., Fu, P.: A multi-period supply chain network design considering carbon emissions. Math. Probl. Eng. Article ID 1581893 (2016)

Rezaee, A., Dehghanian, F., Fahimnia, B., Beamon, B.: Green supply chain network design with stochastic demand and carbon price. Ann. Oper. Res. 250(2), 463–485 (2017)

Sarkar, B., Ullah, M., Kim, N.: Environmental and economic assessment of closed-loop supply chain with remanufacturing and returnable transport items. Comput. Ind. Eng. 111, 148–163 (2017)

Tagaras, G., Zikopoulos, C.: Optimal location and value of timely sorting of used items in a remanufacturing supply chain with multiple collection sites. Int. J. Prod. Econ. 115(2), 424–432 (2008)

Xu, X., Zhang, W., He, P., Xu, X.: Production and pricing problems in make-to-order supply chain with cap-and-trade regulation. Omega 66, 248–257 (2017)

Yang, P.C., Wee, H.M., Chung, S.L., Ho, P.C.: Sequential and global optimization for a closed-loop deteriorating inventory supply chain. Math. Comput. Modell. 52(1), 161–176 (2010)

Author information

Authors and Affiliations

Corresponding author

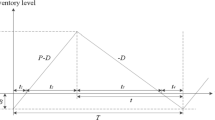

Appendix: Inventory level of repairable item in shop-2

Appendix: Inventory level of repairable item in shop-2

As illustrate in Fig. 2,the inventory differential equations of repairable item during \(T_{R1},\) \(I_1(t)\), can be expressed as

with boundary condition: (i)\( I_1(0)=\beta _1\) and (ii) \( I_1(T_{R1})=0\)

The inventory differential equations of repairable item during production period \(T_{R2}\) is

with boundary condition:(i)\( I_1(0)=0\) and (ii) \( I_2(T_{R2})=\alpha _1\)

The inventory differential equations of repairable item during production period \(T_M\) is

with boundary condition:\(I_3(0)=\alpha _1\)

where \(k_1=(1-\alpha )\delta _p\beta _p\gamma _pD_m\) and \(k_2=((1-\alpha )\delta _s\beta _s\gamma _sD_r\)

The differential equations are solved as

where \(\beta _1=\frac{R-k_2}{a}\bigg [\exp (a T_{R1})-1\bigg ]\) and \(\alpha _1=\frac{k2}{a}\bigg [1-\exp (-a T_{R2})\bigg ]\)

The value of \(\gamma _1\) is \(\beta _1-I(T_{R2})\) that is \(\gamma _1=\beta _1-\alpha _1\)

The inventory holding of repairable item during the time interval [0, T] in shop-2 is

Rights and permissions

About this article

Cite this article

Kundu, S., Chakrabarti, T. Impact of carbon emission policies on manufacturing, remanufacturing and collection of used item decisions with price dependent return rate. OPSEARCH 55, 532–555 (2018). https://doi.org/10.1007/s12597-018-0336-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12597-018-0336-y