Abstract

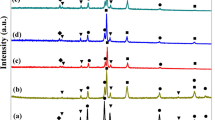

In order to improve the structure and properties of TiC0.3N0.7-TiB2 composite ceramics produced by self-reactive spray forming, TiC0.3N0.7-TiB2 composite ceramics were produced based on the main system of Ti-B4C-C (sucrose as the precuror of carbon)-5 wt.%Al, and the cobalt powders with different mass ratios were added. The effects of cobalt on the structure and properties of the ceramic perform samples were studied. The results show that after the addition of cobalt, the main phases of the sample are still consisted of TiC0.3N0.7 and TiB2, and there are a few TiCo white new phase, meanwhile TiC0.3N0.7 grains are refined, and its relative density, hardness and fracture toughness are improved obviously. With increasing of the content of cobalt, TiC0.3N0.7 grains are refined while TiB2 grain sizes increase, and the relative density and fracture toughness of performs increases while its hardness first decrease and then increase. So the properties of the preforms could be improved by adding cobalt to Ti-B4C-C-5 wt.%Al spray forming system.

Similar content being viewed by others

References

Zhan L., Shen P., Jin S.B., and Jiang Q.C., Combustion synthesis of Ti(C,N)-TiB2 from a Ti-C-BN system, J. Alloys Compd., 2009, 480(2): 315.

Mano j. Kumar B.V., Ram Kumar J., and Basu Bikramjit, Crater wear mechanisms of Ti(C,N)-Ni-WC cermets during dry machining, Int. J. Refract Met. Hard Mater., 2007, 25: 392.

Liu N., Chao S., and Huang X.M., Effects of TiC/TiN addi tion on the microstructure and mechanical properties of ultra-fine grade Ti(C,N)-Ni cermets, J. Eur. Ceram. Soc., 2006, 26: 3861.

Ostberg Gustaf, Buss Katharina, Christensen Mikael, Norgren Susanne, Hans-Olof Andrén, and Mari Daniele, Effect of TaC on plastic deformation of WC-Co and Ti(C,N)-WC-Co, Int. J. Refract Met. Hard Mater., 2006, 24: 145.

Wang J., Liu Y., Zhang P., Peng J.C., Ye J.W., and Tu M.J., Effect of WC on the microstructure and mechanical properties in the Ti(C0.7N0.3)-xWC-Mo2C-(Co,Ni) system, Int. J. Refract. Met. Hard Mater., 2009, 27: 9.

Yao Q., Xing H., Meng L.J., and Sun J., Theoretical calculation of elastic properties of TiB2 and TiB, Chin. J. Nonferrous Met., 2007, 17(8): 1297.

Ronald G. Munro, Material properties of titanium diboride, J. Res. Natl. Inst. Stand. Technol., 2000, 105 (5): 709.

Zhang J.Y., Fu Z.Y., Wang W.M., and Wang H., Microstructure and mechanical properties of TiB2/(Ni+Mo) composites fabricated by hot pressing, J. Mater. Sci. Technol., 2000, 16(6): 634.

Gong L.J., Fu Z.Y., Zhang J.Y., and Miao M.Q., Progress in research on titanium diboride based composites, Mater. Rev., 2004, 18: 18293.

Wang J.J., Liu H.W., Hu W.B., Wen J.H., and Lou H.F., Structure and performance of self-reactive spray formed Ti(C,N)-TiB2 multi-phased ceramic materials, K. Eng. Mater., 2010, 434–435: 33.

Liu H.W., Zhang L., Wang J.J., and Du X.K., Self-reactive spray formed TiC-TiB2 composite ceramic preform, Chin. J. Mater. Res., 2008, 22(3): 274.

Kwona W.T., Park J.S., and Kimb S.W., Effect of WC and group IV carbides on the cutting performance of Ti(C,N) cermet tools, Int. J. Mach. Tools Manuf., 2004, 44: 341.

Li Y., and Liu N., Microstructure and mechanical properties of fine-grained Ti(C,N)-Co cermets, Trans. Mater. Heat Treat., 2008, 29(1): 1.

He C.X., Xia Z.H., and Wang Y.M., Study of Ti(C,N)-based metal ceramic, Chin. J. Rare Met., 1999, 1: 4.

Ettmager P., Ti(C,N) cermets metallurgy and properties, Int. J. Refract. Met. Hard Mater., 1995, 13(6): 343.

Li W.B., Study on Influence of Agglomerate Powders Preparation on TiC-TiB 2 Multi-Phase Ceramics Coatings Sprayed by Reactive Flame Spray, Dissertation for the Master Degree of Ordnance Engineering College, Shijiazhuang, 2006.

Liu H.W., Zhang L., Wang J.J., and Du X.K., Feasibility analysis of self-reactive spray formed TiC-TiB2-based structure ceramic material, Mater. Rev., 2007, 21(7): 139.

Tang J.X., Study of Mechanism of Transient Plastic Phase Processing of Ti-B-C Composites, Dissertation for the Doctor Degree of Tsinghua University, Beijing, 1999.

Zhang X.B., Liu N., Yang H.D., and Zheng Y.C., Boronizing of nano-TiN modified TiC-based cermets, Int. J. Refract. Met. Hard Mater., 2009, 27: 653.

Xue Y., and Wang H.M., Microstructure and wear resistance of laser melted TiCo/Ti5Si3 dual-phase intermetallic alloy, Rare Met. Mater. Eng., 2007, 36(12): 2194.

Yao S., Yuan Y.P., and Han C.L., Effects of starting powders size on the microstructures and properties of Ti(C,N)-based cermets, Carbide (in Chin.), 2005, 22(1): 27.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, W., Zhang, L., Wang, J. et al. Effects of cobalt on structure and properties of TiC0.3N0.7-TiB2 matrix composite ceramics prepared by self-reactive spray forming method. Rare Metals 30 (Suppl 1), 619–623 (2011). https://doi.org/10.1007/s12598-011-0358-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-011-0358-z