Abstract

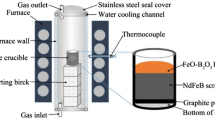

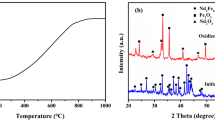

In order to recover valuable rare earth elements from Nd–Fe–B permanent magnet scraps, a high-temperature pyrometallurgical process was developed in this work. The magnet scraps were first pulverized and oxidized at 1000 °C in normal atmosphere. The oxidized mixtures were then selectively reduced by carbon in the temperature range of 1400–1550 °C. In this way, the rare earth elements were extracted to the form of oxides, whereas Fe and B were separated to metal phase. For improving the purity of rare earth oxides, the effects of temperature and reaction time on the reduction of B2O3 in oxide phase were investigated. It is found that increasing reaction temperature and extending reaction time will help the reduction of B2O3 contents in rare earth oxide phase. Almost all rare earth elements can be enriched in the oxide phase with the highest purity of 95 %.

Similar content being viewed by others

References

Sagawa M, Fujimura S, Yamamoto H, Matsuura Y, Hiraga K. Permanent magnet materials based on the rare earth–iron–boron tetragonal compounds. IEEE Trans Magn. 1984;20(5):1584.

Wang RQ, Chen B, Li J, Liu Y, Zheng Q. Structural and magnetic properties of backward extruded Nd–Fe–B ring magnets made by different punch chamfer radius. Rare Met. 2014;33(3):304.

Bi J, Shao S, Guan W, Wang L. State of charge estimation of Li-ion batteries in electric vehicle based on radial-basis-function neural network. Chin Phys B. 2012;21(11):118801.

Itoh M, Miura K, Machida K. Novel rare earth recovery process on Nd–Fe–B magnet scrap by selective chlorination using NH4Cl. J Alloy Compd. 2009;477(1–2):484.

Asabe K, Saguchi A, Takahashi W, Suzuki RO, Ono K. Recycling of rare earth magnet scrap: part I. Carbon removal by high temperature oxidation. Mater Trans. 2001;42(12):2487.

Suzuki RO, Saguchi A, Takahashi W, Yagura T, Ono K. Recycling of rare earth magnet scraps: part II. Oxygen removal by calcium. Mater Trans. 2001;42(12):2492.

Li Y, Evans HE, Harris IR, Jones IP. The oxidation of NdFeB magnets. Oxid Met. 2003;59(1–2):167.

Preston JS, Cole PM, Craig WM, Feather AM. The recovery of rare earth oxides from a phosphoric acid by-product: part 1. Leaching of rare earth values and recovery of a mixed rare earth oxide by solvent extraction. Hydrometallurgy. 1996;41(1):1.

Xiao YF, Feng ZY, Hu GH, Huang L, Huang XW, Chen YY, Li ML. Leaching and mass transfer characteristics of elements from ion-adsorption type rare earth ore. Rare Met. 2015;34(5):357.

Takeda O, Okabe TH, Umetsu Y. Phase equilibrium of the system Ag–Fe–Nd, and Nd extraction from magnet scraps using molten silver. J Alloy Compd. 2004;379(1–2):305.

Okabe TH, Takeda O, Fukuda K, Umetsu Y. Direct extraction and recovery of neodymium metal from magnet. Mater Trans. 2003;44(4):798.

Xu Y, Chumbley LS, Laabs FC. Liquid metal extraction of Nd from NdFeB magnet scrap. J Mater Res. 2000;15(11):2296.

Takeda O, Okabe TH, Umetsu Y. Recovery of neodymium from a mixture of magnet scrap and other scrap. J Alloy Compd. 2006;408–412:387.

Uda T. Recovery of rare earths from magnet sludge by FeCl2. Mater Trans. 2002;43(1):55.

Nakamoto M, Kubo K, Katayama Y, Tanaka T, Yamamoto T. Extraction of rare earth elements as oxides from a neodymium magnetic sludge. Metall Mater Trans B. 2011;43(3):468.

Parida SC, Dash S, Singh Z, Prasad R, Jacob KT, Venugopal V. Thermodynamic studies on NdFeO3. J Solid State Chem. 2002;164(1):34.

Fabrichnaya O, Seifert HJ. Assessment of thermodynamic functions in the ZrO2–Nd2O3–Al2O3 system. Calphad. 2008;32(1):142.

Yamaguchi O, Sugiura K, Mitsui A, Shimizu K. New compound in the system La2O3–Al2O3. J Am Ceram Soc. 1985;68(2):44.

Hamano H, Kuroda Y, Yoshikawa Y, Nagao M. Adsorption of water on Nd2O3: protecting a Nd2O3 sample from hydration through surface fluoridation. Langmuir. 2000;16(17):6961.

Acknowledgments

This study was financially supported by the National Key Basic Research Program of China (No. 2012CB722805).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bian, YY., Guo, SQ., Xu, YL. et al. Recovery of rare earth elements from permanent magnet scraps by pyrometallurgical process. Rare Met. 41, 1697–1702 (2022). https://doi.org/10.1007/s12598-015-0554-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0554-x