Abstract

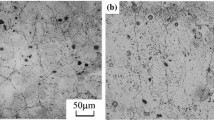

The fatigue fracture was characterized and the fracture behavior was analyzed, using scanning electron microscope (SEM) and electron back-scattered diffraction (EBSD), the fatigue tests of two strain amplitude at room temperature were 0.5% and 1.0% respectively, and the results showed that the fatigue deformation of different strain amplitude produced two typical fatigue fracture morphology, and when the strain amplitude was 1.0%, fatigue fracture mechanism of AZ31 magnesium alloy induced by \(\{ 10\bar{1}2\}\) twins, when the strain amplitude is 0.5%, it was induced by \(\{ 10\bar{1}2\} - \{ 10\bar{1}2\}\) double twins. In the present study, the average thickness of primary twin is ~ 20 μm at amplitude of 0.5% and ~ 80 μm at amplitude of 1.0%. The thickness of \(\{ 10\bar{1}2\}\) primary twins was large enough to activate \(\{ 10\bar{1}2\} - \{ 10\bar{1}2\}\) secondary twins at a high strain amplitude, while the thickness of \(\{ 10\bar{1}2\}\) primary twins was too narrow to activate \(\{ 10\bar{1}2\} - \{ 10\bar{1}2\}\) secondary twins at a low strain amplitude.

Similar content being viewed by others

References

Lee SY, Choo H, Liaw PK, An K, Hubbard CR. A study on fatigue crack growth behavior subjected to a single tensile. Acta Mater. 2011;59(10):495.

Uematsu Y, Kakiuchi T, Tamada K, Kamiya Y. EBSD analysis of fatigue crack initiation behavior in coarse-grained AZ31 magnesium alloy. Int J Fatigue. 2016;84:1.

Yang F, Yin SM, Li SX, Zhang ZF. Crack initiation mechanism of extruded AZ31 magnesium alloy in the very high cycle fatigue regime. Mater Sci Eng, A. 2008;491(1–2):131.

Yue H, Fu P, Peng L, Li Z, Pan J, Ding W. Damage morphology study of high cycle fatigued as-cast Mg–3.0Nd–0.2Zn–Zr (wt%) alloy. Mater Charact. 2016;111:93.

Wen B, Wang F, Jin L, Dong J. Fatigue damage development in extruded Mg–3Al–Zn magnesium alloy. Mater Sci Eng, A. 2016;667:171.

Koike J, Fujiyama N, Ando D, Sutou Y. Roles of deformation twinning and dislocation slip in the fatigue failure mechanism of AZ31 Mg alloys. Scr Mater. 2010;63(7):747.

Chapuis A, Xin YC, Zhou XJ, Liu Q. \(\{ 10\bar{1}2\}\) Twin variants selection mechanisms during twinning, re-twinning and detwinning. Mater Sci Eng A. 2014;612:431.

Yu Q, Jiang Y, Wang J. Cyclic deformation and fatigue damage in single-crystal magnesium under fully reversed strain-controlled tension-compression in the \([10\bar{1}0]\) direction. Scr Mater. 2015;96(2):41.

Jain J, Zou J, Sinclair CW, Poole WJ. Double tensile twinning in a Mg–8Al–0.5Zn alloy. J Microsc-Oxford. 2011;242(1):26.

Hou D, Liu T, Luo L, Lu L, Chen H, Shi D. Twinning behaviors of a rolled AZ31 magnesium alloy under multidirectional loading. Mater Charact. 2017;124:122.

Xin R, Guo C, Jonas JJ, Chen G, Liu Q. Variant selection of \(\{ 10\bar{1}2\} - \{ 10\bar{1}2\}\) double twins during the tensile deformation of an AZ31 Mg alloy. Mater Sci Eng A. 2017;700:226.

Xin YC, Zhou XJ, Lv LC, Liu Q. The influence of a secondary twin on the detwinning deformation of a primary twin in Mg–3Al–1Zn alloy. Mater Sci Eng, A. 2014;606(6):81.

Jäger A, Ostapovets A, Molnár P, Lejček P. \(\{ 10\bar{1}2\} - \{ 10\bar{1}2\}\) Double twinning in magnesium. Philos Mag Lett. 2011;91(8):537.

Tan L, Zhang X, Sun Q, Yu J, Huang G, Liu Q. \(\{ 10\bar{1}2\} - \{ 10\bar{1}2\}\) double tensile twinning in a Mg–3Al–1Zn alloy sheet during cyclic deformation. Mater Sci Eng A. 2018;711:205.

Ando D, Koike J, Sutou Y. The role of deformation twinning in the fracture behavior and mechanism of basal textured magnesium alloys. Mater Sci Eng, A. 2014;600(2):145.

Li D, Xue HS, Yang G. Microstructure and mechanical properties of Mg–6Zn–0.5Y magnesium alloy prepared with ultrasonic treatment. Rare Met. 2017;36(8):622.

Yin SM, Yang F, Yang XM, Wu SD, Li SX, Li GY. The role of twinning–detwinning on fatigue fracture morphology of Mg–3%Al–1%Zn alloy. Mater Sci Eng, A. 2008;494(1–2):397.

Begum S, Chen DL, Xu S, Luo AA. Low cycle fatigue properties of an extruded AZ31 magnesium alloy. Int J Fatigue. 2009;31(4):726.

Mughrabi H. Microstructural fatigue mechanisms: cyclic slip irreversibility, crack initiation, non-linear elastic damage analysis. Int J Fatigue. 2013;572(12):2.

Li Q, Yu Q, Zhang J, Jiang Y. Effect of strain amplitude on tension-compression fatigue behavior of extruded Mg6Al1ZnA magnesium alloy. Scr Mater. 2010;62(10):778.

Wu L, Agnew SR, Brown DW, Stoica GM, Clausen B, Jain A, Fielden DE, Liaw PK. Internal stress relaxation and load redistribution during the twinning–detwinning-dominated cyclic deformation of a wrought magnesium alloy, ZK60A. Acta Mater. 2008;56(14):3699.

Vinogradov A, Vasilev E, Linderov M, Merson D. In situ observations of the kinetics of twinning–detwinning and dislocation slip in magnesium. Mater Sci Eng, A. 2016;676:351.

Hama T, Kitamura N, Takuda H. Effect of twinning and detwinning on inelastic behavior during unloading in a magnesium alloy sheet. Mater Sci Eng, A. 2013;583(11):232.

Wu BL, Duan GS, Du XH, Song LH, Zhang YD, Philippe MJ, Esling C. In situ investigation of extension twinning–detwinning and its effect on the mechanical behavior of AZ31B magnesium alloy. Mater Des. 2017;132:57.

Yu Q, Zhang JX, Jiang YY. Direct observation of twinning–detwinning–retwinning on magnesium single crystal subjected to strain-controlled cyclic tension–compression in \([0001]\) direction. Philos Mag Lett. 2011;91:757.

Yu Q, Zhang JX, Jiang YY, Li QZ. Effect of strain ratio on cyclic deformation and fatigue of extruded AZ61A magnesium alloy. Int J Fatigue. 2012;44(9):225.

Tan L, Zhang X, Sun Q, Yu J, Huang G, Liu Q. Pyramidal slips in high cycle fatigue deformation of a rolled Mg–3Al–1Zn magnesium alloy. Mater Sci Eng, A. 2017;699:247.

Mu SJ, Jonas JJ, Gottstein G. Variant selection of primary, secondary and tertiary twins in a deformed Mg alloy. Acta Mater. 2012;60(5):2043.

Xin Y, Jiang J, Chapuis A, Wang M, Liu Q. Plastic deformation behavior of AZ31 magnesium alloy under multiple passes cross compression. Mater Sci Eng, A. 2012;532(3):50.

Barnett MR, Keshavarz Z, Beer AG, Atwell D. Influence of grain size on the compressive deformation of wrought Mg–3Al–1Zn. Acta Mater. 2004;52(17):5093.

Wu L, Jain A, Brown DW, Stoica GM, Agnew SR, Clausen B, Fielden DE, Liaw PK. Twinning–detwinning behavior during the strain-controlled low-cycle fatigue testing of a wrought magnesium alloy, ZK60A. Acta Mater. 2008;56(4):688.

Dong S, Yu Q, Jiang Y, Dong J, Wang F, Ding W. Electron backscatter diffraction observations of twinning–detwinning evolution in a magnesium alloy subjected to large strain amplitude cyclic loading. Mater Des. 2015;65:762.

Barnett MR, Keshavarz Z, Beer AG, Ma X. Non-Schmid behaviour during secondary twinning in a polycrystalline magnesium alloy. Acta Mater. 2008;56(1):5.

Lentz M, Risse M, Schaefer N, Reimers W, Beyerlein IJ. Strength and ductility with \(\{ 10\bar{1}1\} - \{ 10\bar{1}2\}\) double twinning in a magnesium alloy. Nat commun. 2016;7:11068.

Barnett MR. Twinning and the ductility of magnesium alloys Part II. “Contraction” twins. Mater Sci Eng, A. 2007;464(1):8.

Barnett MR. Twinning and the ductility of magnesium alloys Part I: “Tension” twins. Mater Sci Eng, A. 2007;464(1):1.

Xu DK, Han EH. Relationship between fatigue crack initiation and activated \(\{ 10\bar{1}2\}\) twins in as-extruded pure magnesium. Scr Mater. 2013;69(9):702.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Nos. 51671040, 50890170 and 51421001), the National Basic Research Program of China (No. 2010CB631004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tan, L., Zhang, XY., Xia, T. et al. Fracture morphology and crack mechanism in pure polycrystalline magnesium under tension–compression fatigue testing. Rare Met. 39, 162–168 (2020). https://doi.org/10.1007/s12598-018-01200-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-01200-3