Abstract

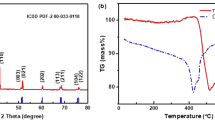

In the family of anodes for sodium-ion batteries, alloy-type anodes possess higher theoretical specific capacity than carbon anodes. The theoretical specific capacity of metallic Sn is 847 mAh·g−1. However, the tin-based material undergoes a large volume expansion during the sodium-ion intercalation process, which leads to the crack and pulverization of the electrode, consequently resulting in a significant capacity loss. In this paper, a yolk–shell-structured Sn–Co@void@C composite composed of a Sn–Co alloy core, a carbon shell and void space between the core and shell is designed and synthesized. Compared with the carbon-encapsulated SnCo without void space (Sn–Co@C) and carbon-encapsulated pure Sn core shell with void space (Sn@void@C), this composite exhibits improved reversibility, cyclic performance and rate capability. This work highlights the important roles of Co in the alloy and the void space between the core and the shell. The former can not only buffer the volume expansion of Sn, but also act as an electrical conductor. The void space can further tolerate the volume expansion of the Sn–Co core. Owing to this unique microstructure, the Sn–Co@void@C composite shows an initial reversible capacity of 591.4 mAh·g−1, at a current density of 50 mA·g−1. After 100 charge/discharge cycles at 100 mA·g−1, the composite still delivers 330 mAh·g−1.

Graphic abstract

摘要

在钠离子电池负极材料中, 合金型负极比碳负极具有更高的理论比容量。金属锡的理论比容量为847 mAh·g-1, 然而, 锡基材料在钠离子嵌入过程中会产生较大的体积膨胀, 这会造成电池材料的开裂和粉化脱落, 最终导致显著的容量衰减。本文设计并合成了一种蛋黄-壳型Sn-Co@void@C复合材料, 该材料由Sn-Co合金核和碳壳组成, 在核、壳间存在一定的空隙。对比没有留空隙的碳包覆Sn-Co合金 (SnCo@C) 和留了空隙的碳包覆纯Sn (Sn@void@C), 这种复合材料表现出了更好的可逆性、循环性能和倍率性能。本文突出了合金中Co以及核壳间空隙的作用, 前者不仅能缓冲Sn的体积膨胀, 还能作为一种良好的电子导体, 而后者可进一步容纳Sn-Co核的体积膨胀。因具有这种独特的微观结构, Sn-Co@void@C复合材料在50 mA·g-1电流密度下的首次可逆比容量为591.4 mAh·g-1。在100 mA·g-1电流密度下经过100周充放电循环后, 该复合材料还有330 mAh·g-1的可逆比容量。

Similar content being viewed by others

References

Wang H, Yao T, Li C, Meng L, Cheng Y. Constructing three-dimensional ordered porous MoS2/C hierarchies for excellent high-rate long-life pseudocapacitive sodium storage. Chem Eng J. 2020;397:125385.

Yu P, Tang W, Wu FF, Zhang C, Luo HY, Liu H, Wang ZG. Recent progress in plant-derived hard carbon anode materials for sodium-ion batteries: a review. Rare Met. 2020;39(9):1019.

Zhou ZM, Zhou XY, Zhang M, Mu SN, Liu QR, Tang YB. In situ two-step activation strategy boosting hierarchical porous carbon cathode for an aqueous Zn-based hybrid energy storage device with high capacity and ultra-long cycling life. Small. 2020;16(35):2003174.

Xie DH, Zhang M, Wu Y, Xiang L, Tang YB. A flexible dual-ion battery based on sodium-ion quasi-solid-state electrolyte with long cycling life. Adv Funct Mater. 2020;30(5):1906770.

Pan QG, Gong DC, Tang YB. Recent progress and perspective on electrolytes for sodium/potassium-based devices. Energy Storage Mater. 2020;31:328.

Ji BF, He HY, Yao WJ, Tang YB. Recent advances and perspectives on calcium-ion storage: key materials and devices. Adv Mater. 2020. https://doi.org/10.1002/adma.202005501.

Palomares V, Serras P, Villaluenga I, Hueso KB, Carretero-González J, Rojo T. Na-ion batteries, recent advances and present challenges to become low cost energy storage systems. Energy Environ Sci. 2012;5(3):5884.

Hwang JY, Myung ST, Sun YK. Sodium-ion batteries: present and future. Chem Soc Rev. 2017;46(12):3529.

Zheng SM, Tian YR, Liu YX, Wang S, Hu CQ, Wang B, Wang KM. Alloy anodes for sodium-ion batteries. Rare Met. 2020. https://doi.org/10.1007/s12598-020-01605-z.

Kundu D, Talaie E, Duffort V, Nazar LF. The emerging chemistry of sodium ion batteries for electrochemical energy storage. Angew Chem Int Ed. 2015;54(11):3431.

Huang B, Pan ZF, Su XY, An L. Tin-based materials as versatile anodes for alkali (earth)-ion batteries. J Power Sources. 2018;395:41.

Mu SN, Liu QR, Kidkhunthod P, Zhou XL, Wang WL, Tang YB. Molecular grafting towards high-fraction active nanodots implanted in N-doped carbon for sodium dual-ion batteries. Natl Sci Rev. 2020. https://doi.org/10.1093/nsr/nwaa178.

Wei XJ, Wang XP, Tan X, An QY, Mai LQ. Nanostructured conversion-type negative electrode materials for low-cost and high-performance sodium-ion batteries. Adv Funct Mater. 2018;28(46):1804458.

Kim H, Kim H, Ding Z, Lee MH, Lim K, Yoon G, Kang K. Recent progress in electrode materials for sodium-ion batteries. Adv Energy Mater. 2016;6(19):1600943.

Bai PX, He YW, Xiong PX, Zhao XX, Xu K, Xu YH. Long cycle life and high rate sodium-ion chemistry for hard carbon anodes. Energy Storage Mater. 2018;13:274.

Zhang H, Hasa I, Passerini S. Sodium-ion batteries: beyond insertion for Na-ion batteries: nanostructured alloying and conversion anode materials. Adv Energy Mater. 2018;8(17):1702582.

Wu L, Hu XH, Qian JF, Pei F, Wu FY, Mao RJ, Ai XP, Yang HX, Cao YL. Sb–C nanofibers with long cycle life as an anode material for high-performance sodium-ion batteries. Energy Environ Sci. 2014;7(1):323.

Ying HJ, Han WQ. Metallic Sn-based anode materials: application in high-performance lithium-ion and sodium-ion batteries. Adv Sci. 2017;4(11):1700298.

Zheng SQ, Wu ZH, Wang JT, Zhang XJ. Performance of high capacity silicon/carbon anodes with different pore structures. Chin J Rare Met. 2020;44(3):225.

Fang R, Miao C, Mou HY, Xiao W. Facile synthesis of Si@TiO2@rGO composite with sandwich-like nanostructure as superior performance anodes for lithium ion batteries. J Alloys Compd. 2020;818:152884.

Zhang WC, Mao JF, Li S, Chen ZX, Guo ZP. Phosphorus-based alloy materials for advanced potassium-ion battery anode. J Am Chem Soc. 2017;139(9):3316.

Zhang WC, Liu YJ, Guo ZP. Approaching high-performance potassium-ion batteries via advanced design strategies and engineering. Sci Adv. 2019;5(5):eaav7412.

Zhang WC, Pang WK, Sencadas V, Guo ZP. Understanding high-energy-density Sn4P3 anodes for potassium-ion batteries. Joule. 2018;2(8):1534.

Ge XL, Li ZQ, Yin LW. Metal-organic frameworks derived porous core/shell CoP@C polyhedrons anchored on 3D reduced graphene oxide networks as anode for sodium-ion battery. Nano Energy. 2017;32:117.

Wang JK, Zhu L, Li F, Yao TH, Liu T, Cheng YH, Yin ZY, Wang HK. Synergizing phase and cavity in CoMoOxSy yolk–shell anodes to co-enhance capacity and rate capability in sodium storage. Small. 2020;16(33):2002487.

Zhao LZ, Wu HH, Yang CH, Zhang QB, Zhong GM, Zheng ZM, Chen HX, Wang JM, He K, Wang BL, Zhu T, Zeng XC, Liu ML, Wang MS. Mechanistic origin of the high performance of yolk@shell Bi2S3@N-doped carbon nanowire electrodes. ACS Nano. 2018;12(12):12597.

Zheng P, Liu T, Guo SW. Micro-nano structure hard carbon as a high performance anode material for sodium-ion batteries. Sci Rep. 2016;6(1):35620.

Cheng YY, Huang JF, Li JY, Xu ZW, Cao LY, Qi H. Synergistic effect of the core-shell structured Sn/SnO2/C ternary anode system with the improved sodium storage performance. J Power Sources. 2016;324:447.

Yang CH, Liang XH, Ou X, Zhang QB, Zheng HS, Zheng FH, Wang JH, Huang K, Liu ML. Heterostructured nanocube-shaped binary sulfide (SnCo)S2 interlaced with S-doped graphene as a high-performance anode for advanced Na+ batteries. Adv Funct Mater. 2019;29(9):1807971.

Xiao LF, Cao YL, Xiao J, Wang W, Kovarik L, Nie ZM, Liu J. High capacity, reversible alloying reactions in SnSb/C nanocomposites for Na-ion battery applications. Chem Commun. 2012;48(27):3321.

Cao YL, Xiao LF, Sushko ML, Wang W, Schwenzer B, Xiao J, Nie ZM, Saraf LV, Yang ZG, Liu J. Sodium ion insertion in hollow carbon nanowires for battery applications. Nano Lett. 2012;12(7):3783.

Xu YH, Zhu YJ, Liu YH, Wang CS. Electrochemical performance of porous carbon/tin composite anodes for sodium-ion and lithium-ion batteries. Adv Energy Mater. 2013;3(1):128.

Huang B, Li XH, Pei Y, Li S, Cao X, Massé RC, Cao GZ. Novel carbon-encapsulated porous SnO2 anode for lithium-ion batteries with much improved cyclic stability. Small. 2016;12(14):1945.

Wang Y, Li N, Hou CX, He B, Li JJ, Dang F, Wang J, Fan YQ. Nanowires embedded porous TiO2@C nanocomposite anodes for enhanced stable lithium and sodium ion battery performance. Ceram Int. 2020;46(7):9119.

Hu XJ, Wang G, Wang BB, Liu XJ, Wang H. Co3Sn2/SnO2 heterostructures building double shell micro-cubes wrapped in three-dimensional graphene matrix as promising anode materials for lithium-ion and sodium-ion batteries. Chem Eng J. 2019;355:986.

Wang HQ, Sun YN, Zhang XH, Ding YJ, Wang Y, Wu XM, Li QY. Scalable synthesis of SnCo/NC composite as a high performance anode material for lithium-ion batteries. J Alloy Compd. 2019;775:975.

Fang LM, Zu XT, Li ZJ, Zhu S, Liu CM, Wang LM, Gao F. Microstructure and luminescence properties of Co-doped SnO2 nanoparticles synthesized by hydrothermal method. J Mater Sci Mater Electron. 2008;19(8–9):868.

Kim JK, Kim JH, Kang YC. Electrochemical properties of multicomponent oxide and selenide microspheres containing Co and Mo components with several tens of vacant nanorooms synthesized by spray pyrolysis. Chem Eng J. 2018;333:665.

Wang Y, Zhang FC, Yu Y, Yang YQ, Mao PY, Guo WB, Rao S, Wang DX, Li QY. Tailoring the carbon shell thickness of SnCo@nitrogen-doped carbon nanocages for optimized lithium storage. Electrochim Acta. 2018;282:799.

Li T, Gulzar U, Zaccaria RP, Capiglia C, Hackney SA, Aifantis KE. Damage formation in Sn film anodes of Na-ion batteries. J Phys Chem C. 2019;123(24):15244.

Winter M, Besenhard JO. Electrochemical lithiation of tin and tin-based intermetallics and composites. Electrochim Acta. 1999;45(1):31.

Zuo DC, Song SC, An CS, Tang LB, He ZJ, Zheng JC. Synthesis of sandwich-like structured Sn/SnOx@MXene composite through in-situ growth for highly reversible lithium storage. Nano Energy. 2019;62:401.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51804089), Guangxi Natural Science Foundation (Nos. 2017GXNSFBA198141 and 2017GXNSFAA198230) and the Foundation of Guilin University of Technology (No. GLUTQD2017005).

Author information

Authors and Affiliations

Corresponding author

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, S., Li, XZ., Huang, B. et al. Controllable construction of yolk–shell Sn–Co@void@C and its advantages in Na-ion storage. Rare Met. 40, 2392–2401 (2021). https://doi.org/10.1007/s12598-021-01729-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-021-01729-w