Abstract

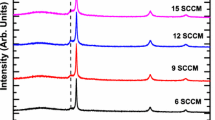

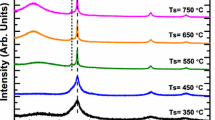

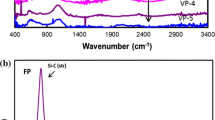

Cubic nanocrystalline silicon carbide (3C-SiC) films have been deposited by using the hot wire chemical vapor deposition (HW-CVD) method at a low substrate temperature and at high deposition rate. Structural, optical and electrical properties of these films have been investigated as a function of H2 dilution ratio. The formation of 3C-SiC films has been confirmed from low angle XRD analysis, Raman spectroscopy, Fourier transform infrared (FTIR) spectroscopy, x-ray photoelectron spectroscopy (XPS) and dark and photoconductivity measurements. The FTIR spectroscopy analysis revealed that the bond densities of Si-H and C-H decrease while that of Si-C increases with increase in the H2 dilution ratio. The total hydrogen content decreases with increase in H2 dilution ratio and was found < 15 at. % over the entire range of H2 dilution ratio studied whereas the band gap show an increasing trend with increase in the H2 dilution ratio.

Similar content being viewed by others

References

Yang X, Zhao-hui C, Feng C (2014). J Asian Ceram Soc 2:305–309

Chen T, Huang Y, Dasgupta A, Luysberg M, Houben L, Yang D, Carius R, Finger F (2012). Sol Energy Mater Sol Cells 98:370–378

Fuchs F, Soltamov V, Vath S, Baranov P, Mokhov E, Astakhov G, Dyakonov V (2013). Sci Rep 3(1-4):1637

Windischmann H (1991). J Vac Sci Technol A 9:2459–2463

Marsi P (1998). Surf Sci Rep 48:1–51

Li S, Cao Y, Xu J, Rui Y, Li W, Chen K (2013). Appl Surf Sci 270:287–291

Ricciardi C, Fanchini G, Mandracci P (2003). Diamond Relat Mater 12:1236–1240

Singh A, Chandra S, Kumar S, Bose G (2012). J Micromech Microeng 22(2):025010

Filipescu M, Velisa G, Ion V, Andrei A, Scintee N, Ionescu P, Stanciu S, Pantelica D, Dinescu M (2011). J Nucl Mater 416:18–21

Wang Q, Fu S, Qu S, Liu W (2007). Solid State Commun 144:277–281

Verucchi R, Aversa L, Nardi M, Taioli S, Beccara S, Alfe D, Nasi L, Rossi F, Salviati G, Iannotta S (2012). J Am Chem Soc 134:17400–17403

Mandracci P (2001) Ph. D Thesis, Trento University, Italy

Jeong S, Nam D, Kim B, Yoon J, Lee M, Kim K, Yoon Y, Seo W (2014). Appl Phys Express 7(2):025501

Yang X, Zhao-hui C, Feng C (2014). J Asian Ceram Soc 2:305–309

Panda S, Sengupta J, Jacob C (2010). J Nanosci Nanotechnol 10:3046–3052

Ricciardi C, Primiceli A, Germani G, Rusconi A, Giorgis F (2006). J Non-Cryst Solids 352:1380–1383

Rajagopalan T, Wang X, Lahlouh B, Ramkumar C, Dutta P, Gangopadhyay S (2003). J Appl Phys 94:5252–5260

Dasgupta A, Klein S, Houben L, Carius R, Finger F, Luysberg M (2008). Thin Solid Films 516:618–621

Klein S, Carius R, Finger F, Houben L (2006). Thin Solid Films 501:169–172

Chen T, Huang Y, Yang D, Carius R, Finger F (2011). Thin Solid Films 519:4511–4515

Chen T, Huang Y, Dasgupta A, Luysberg M, Houben L, Yang D, Carius R, Finger F (2012). Sol Energy Mater Sol Cells 98:370–376

Miyajima S, Yamada A, Konagai M (2006). Thin Solid Films 501:186–189

Tabata A, Komura Y (2007). Surf Coat Technol 201:8986–8990

Tabata A, Komura Y, Narita T, Kondo A (2009). Thin Solid Films 517:3516–3519

Hoshide Y, Komura Y, Tabata A, Kitagawa A, Kondo A (2009). Thin Solis Films 517:3520–3523

Tehrani F, Badaruddin M, Rahbari R, Muhamad M, Rahman S (2012). Vacuum 86:1150–1154

Waman V, Kamble M, Pramod M, Funde A, Sathe V, Gosavi S, Jadkar S (2011). J Nano-Electron Phys 3:590–600

Swanepoel R (1983). J Phys E: Sci Instrum 16:1214–1222

Abrbrosone G, Capezzuto P P, Catalanotti S, Coscia U, Mormone S (2006). Philos Mag B 80(/4):497–506

Mori M, Tabata A, Mizutani T (2006). Thin Solid Films 501:177–180

Cheng Q, Long J, Ni Z, Rider A, Ostrikov K (2008). J Phys D: Appl Phys 41:055406–055414

Karimi B, Dow A, Kherani N (2013) Proceedings of 5th International Nanoelectronics Conference (INEC), Singapore, p 160

Lucovsky G, Nemanich R, Knights J (1979). Phys Rev B 19:2064

Tabata A, Kuroda M, Mori M, Mizutani T, Suzuoki Y (2004). J Non-Cryst Solids 338:521–524

Ambrosone G, Capezzuto P, Catalanotti S, Coscia U, Mormone S (2009). Phil Maz B 80:497–506

Kuenle M, Janz S, Eibl O, Berthold C, Presser V, Nickel K (2009). Mater Sci Eng B 159:355–360

Kaneko T, Nemoto D, Horiguchi A, Miyakawa N (2005). J Cryst Growth 275:e1097–e1101

Ray S, Das D, Barua A (1987). Sol Energy Mater 15:43–57

Basa K, Smith F (1990). Mater Res Soc Symp Proc 162:439

Shanks H, Faug C, Ley L, Cardona M, Demand F, Kalbitzer S (1980). Phys Status Solidi B 100:43–56

Liao F, Park S, Larson J, Zachariah M, Girshick S (2003). Mater Lett 57:1982–1986

Nakashima S, Harima H (1997). Phys Status Solidi A 162:39–64

Tanaka T, Maruyama E, Shimida T, Okamoto H (1999) Amorphous Silicon John Wiley and Sons Ltd, p 78

Richter H, Wang Z, Ley L (1981). Solid State Commun 39 :625–629

Swain B, Dusane R (2006). Mater Chem Phys 99:240–246

Feldman D, Parker J, Choyke W, Patrik L (1968). Phys Rev 173:787–793

Chen T, Kohler F, Heidt A, Huang Y, Finger F, Carius R (2011). Thin Solid Films 519:4511–4515

Karch K, Pavone P, Windl W, Shutt O, Strauch D (1994). Phys Rev B 50:17054–17063

Wu T, Shen H, Cheng B, Pan Y, Liu B, Shen J (2011). Appl Surf Sci 258:999–1003

Ei Khakani M, Chaker M, Jean J, Boily S, Pepin H, Kieffer J, Gujrathi S (1993). J Appl Phys 74:2834–2840

Soloman I, Schmidt M, Selemaud C, Driss K (1988). Phys Rev B 38:13263–13270

Tauc J, Grigorovici R, Vancu A (1966). Phys Status Solidi 15 :627–637

Saitoh T, Shimada T, Migitaka M (1983). J Non-Cryst Solids 59:715–718

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kamble, M., Waman, V., Mayabadi, A. et al. Synthesis of Cubic Nanocrystalline Silicon Carbide (3C-SiC) Films by HW-CVD Method. Silicon 9, 421–429 (2017). https://doi.org/10.1007/s12633-015-9358-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-015-9358-8