Abstract

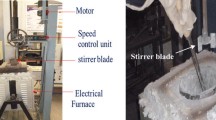

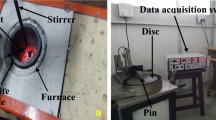

Al7075-SiC composites containing three different weight percentages, 5 %, 10 %, and 15 % of SiC, have been fabricated by powder metallurgy. Mechanical and tribological characteristics of Al7075-SiC composites have been investigated under dry sliding conditions. The microstructural characterization confirms the even dispersion of SiC particles and good interfacial bonding between the reinforcement – matrix. Improved mechanical characteristics are noticed for 15 %SiC composite compared to both 5 & 10 %SiC composites. Dry sliding wear examinations have been carried out using pin-on-disc equipment. Wear loss and coefficient of friction of samples were measured, and the variation of cumulative wear loss with load is linear for all the composites. The wear mechanism appears to be oxidative for all specimens under the given conditions of load and sliding distance as indicated by the optical microscopic worn out surfces. Further, the experimentation that the wear loss and coefficient of friction decrease linearly with increase increasing weight % of silicon carbide. Response surface methodology confirms that wt.% SiC is positively influencing both wear loss and coefficient of friction. The best mechanical and tribological properties have been exhibited by the composite reinforced with 15 % SiC.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this article.

References

Mazahery A, Shabani MO (2012) Study on microstructure and abrasive wear behavior of sintered Al matrix composites. Ceram Int 38:4263–4269

Sattari S, Masha J (2017) Effect of volume fraction of reinforcement and milling time on physical and mechanical properties of Al7075–Sic composites fabricated by powder metallurgy method. Powder Metall Met Ceram 56(5–6):283–292

Mulugundam SS, Guvvala P (2018) Tribological behaviour of aluminum silicon carbide functionally graded material. Tribol Ind 40(2):247–253

Boopathi M, Arulshri KP, Natesan I (2013) Evaluation of mechanical properties of Aluminium alloy 2024 reinforced with silicon carbide and fly ash hybrid metal matrix composites. Am J Appl Sci 10(3):219–229

Veeresh GB, Rao C, Selvaraj N (2011) Mechanical and tribological behavior of particulate reinforced aluminum metal matrix composites – a review. J Miner Mater Charact Eng 10(1):59–91

Bhushan K, Kumar S (2011) Influence of SiC particles distribution and their weight % on 7075 Al aloy. J Mater Eng Perform 20(2):317–323

Mulugundam SS, Guvvala P (2020) Manufacturing, microstructural and mechanical characterization of powder metallurgy processed Al7075/SiC metal matrix composite. Mater Today Proc

Nassar AE, Nassar EE (2017) Properties of aluminum matrix Nano composites prepared by powder metallurgy processing. Eng Sci 29:295–299

Vani V, Chak S (2018) The effect of process parameters in aluminum metal matrix composites with powder metallurgy. Manuf Rev 5(7):1–13

Vencl A, Rac A, Robica I (2004) Tribological behaviour of Al-based MMCs and their application in automotive industry. Tribol Ind 26(3&4):31–38

Mulugundam SS, Guvvala P (2019) Manufacturing and mechanical behavior of (Al/SiC) functionally graded material using powder metallurgy technique. Int J Innov Technol Explor Eng 8(9):1835–1839

Reddy PV, Prasad PP, Krishnudu DM, Goud EV (2019) An investigation on mechanical and wear characteristics of Al 6063/TiC metal matrix composites using RSM. J Bio Tribo Corrosion 5(4):1–10

Faisal N, Kumar K (2018) Mechanical and tribological behaviour of nano scaled silicon carbide reinforced aluminium composites. J Exp Nanosci 13:S1–S13

Kumar N, Gautam G, Gautam RK, Mohan A (2016) Synthesis and characterization of TiB2 reinforced aluminium matrix composites: a review. J Inst Eng (India) Ser D 97:233–253

Surya MS, Prasanthi G (2021) Effect of silicon carbide weight % and number of layers on microstructural and mechanical properties of Al7075/SiC functionally graded material. Silicon. https://doi.org/10.1007/s12633-020-00865-9

Saravanan C, Subramanian K, Veeramani A, Sathish S (2018) Tribological behavior of AA7075-TiC composites by powder metallurgy. Ind Lubr Tribol 70:1

Erdemir F, Canakci A, Varol T (2015) Microstructural characterization and mechanical properties of functionally graded Al2024/SiC composites prepared by powder metallurgy techniques. Trans Nonferrous Metals Soc China 25(11):3569–3577

Tripathy A, Sarangi SK, Panda R (2017) Fabrication of functionally graded composite material using powder metallurgy route, an overview. Int J Mech Prod Eng Res Dev 7:135–145

Hillary J, Maria J, Ramamoorthi R, Joseph J, Jim D, Samuel C, Jerold S (2019) A study on microstructural effect and mechanical behaviour of Al6061–5 % SiC–TiB2 particulates reinforced hybrid metal matrix composites. J Compos Mater

Dey D, Bhowmik A, Biswas A (2020) Effect of SiC content on mechanical and tribological properties of Al2024-SiC composites. Silicon

Aigbodion VS, Hassan SB (2007) Effects of silicon carbide reinforcement on microstructure and properties of cast Al–Si–Fe/SiC particulate composites. Mater Sci Eng A 447(1–2):355–360

Zhu J, Jiang W, Li G, Guan F, Yang Y, Zitian F (2020) Microstructure and mechanical properties of SiCnp/Al6082 aluminum matrix composites prepared by squeeze casting combined with stir casting. J Mater Process Technol 283:116699

Singh N, Mir IUH, Raina A, Anand A, Kumar V, Sharma SM (2018) Synthesis and tribological investigation of Al-SiC based nano hybrid composite. Alex Eng J 57(3):1323–1330

Kurapati VB, Kommineni R, Sundarrajan S (2018) Statistical analysis and mathematical modeling of dry sliding wear parameters of 2024 aluminium hybrid composites reinforced with fly ash and SiC particles. Trans Indian Inst Metals 71(7):1809–1825

Rao JB, Rao DV, Prasad KS, Bhargava NRMR (2012) Dry sliding wear behaviour of fly ash particles reinforced AA 2024 composites. Mater Sci-Pol 30(3):204–211

Dey D, Biswas A (2020) Comparative study of physical, mechanical and tribological properties of Al2024 alloy and SiC-TiB2 composites. Silicon

Dharmalingam S, Subramanian R, Somasundara K, Anandavel VB (2011) Optimization of tribological properties in aluminum hybrid metal matrix composites using Gray-Taguchi method. J Mater Eng Perform 20(8):1457–1466.

Surya MS, Prasanthi G (2021) Effect of SiC weight % on tribological characteristics of Al7075/SiC composites. Silicon. https://doi.org/10.1007/s12633-020-00885-5

Surya MS, Prasanthi G, Gugulothu SK (2021) Investigation of mechanical and wear behaviour of Al7075/SiC composites using response surface methodology. Silicon. https://doi.org/10.1007/s12633-020-00854-y

Author information

Authors and Affiliations

Contributions

Mulugundam Siva Surya: Conceptualization, Methodology, Experimentation, Result Analysis, Writing- Original draft preparation., S.K. Gugulothu: Supervision.

Corresponding author

Ethics declarations

Conflict of Interest

No Potential conflict of interest was reported by the authors.

Human and Animal Rights

The present study work was not conducted on human or experimental animals where national or international guidelines are used for the protection of human subjects and animal welfare.

Consent to Participate

Not Applicable.

Consent for Publication

We confirm that the manuscript has been read and approved by all named authors and that there are no other persons who satisfied the criteria for authorship but are not listed. We further confirm that all the authors listed in the manuscript has been approved by all of us.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Surya, M.S., Gugulothu, S.K. Fabrication, Mechanical and Wear Characterization of Silicon Carbide Reinforced Aluminium 7075 Metal Matrix Composite. Silicon 14, 2023–2032 (2022). https://doi.org/10.1007/s12633-021-00992-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-00992-x