Abstract

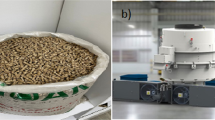

Many European countries are developing the use of pellets or wood briquettes for the supplying of local energy. Many industries are being forced to replace fossil fuels with biomass because of its neutrality in relation to CO2 emissions, thus creating an interesting market for pellets. In Portugal, the most common undergrowth includes: esteva (Cistus ladanifer), tojo (Ulex europaeus), giesta (Sarothamus scoparius), feto (Pteridium aquilium) and silva (Rubus ulmifolius). These undergrowth specimen are attractive due to the large volume available, but are not usually used for making pellets. It is possible to prevent large fires cleaning the forests, but this is an expensive task that could be compensated if the undergrowth can have some commercial value. The use of the common undergrowth for the manufacture of pellets and briquettes will allow the undergrowth to be considered not as a problem to be removed from the forest but an opportunity as renewable energy. The aim of this work is to obtain pellets with standard properties and evaluate the parameters that can qualify the performance of these pellets: moisture content, particle size distribution, high heating value, height of flame and burning time, pressure and temperature of the pelletizing process and mechanical durability. The pelletizing process was first simulated on laboratorial scale using small amounts of each vegetal specimen which was pressed in a heated mould. Some samples were submitted to a torrefaction treatment. After the laboratorial screening, the selected material was processed using a pellet mill to prepare pellets with 6 mm of diameter. The durability test was performed using a tumbling device following the ASAE S 269.4 standard. Burning tests of pellets with the same weight were performed and video images analysed, where height of flame and ignition time were measured. It was found that undergrowth pellets had good power of agglomeration and allow an easy ignition. The apparent density varies around 1,260 kg/m3. The moisture content of different pellet varied between 2.79 and 7.46 %, ash content was less than 3 %, the calorific value is between 16 and 18 kJ/kg, the durability results respect the values recommended by standards. After ignition the flame increases to an average height of 25 mm. The total burning time was in all cases dominated by the cinder combustion without visible flame and the total complete burning time varied between 400 and 600 s. The results showed that it is possible to produce pellets of undergrowth with physical and thermochemical characteristics similar to the existing in the market at the present time.

Similar content being viewed by others

References

Barreto, E.J., Rendeiro, G., Nogueira, M.: Combustion and Gasification of Solid Biomass: Energy Solutions for the Amazon. Ministério de Minas e Energia, Brasilia (2008) (in Portuguese)

Junginger, M., Bolkesjø, T., Bradley, D., Dolzan, P., Faaij, A., Heinimisö, J., et al.: Developments in international bioenergy trade. Biomass Bioenergy 32(8), 717–729 (2008)

Cavalheiro, J.: How to Introduce Biomass for Economic Circuit. Guimarães, Centre for Waste Recovery (2010) (in Portuguese)

Kaliyan, N., Morey, R.: Densification characteristics of corn Stover and switch grass. Am. Soc. Agric. Biol. Eng. 52(3), 907–920 (2009)

Al-Widyan, M.I., Al-Jilal, H.F., Abu-Zreig, M.M., Abu-Hamdeh, N.H.: Physical durability and stability of olive cake briquettes. Can. Biosyst. Eng. 443, 41–45 (2002)

Granada, E., López González, L.M., Míguez, J.L., Moran, J.: Fuel lignocellulosic briquettes, die design and products study. Renewable Energy 27, 561–573 (2002)

Suárez, J.A., Luengo, C.A., Felfli, F.F., Bezzon, G., Beatón, P.A.: Thermochemical properties of Cuban biomass. Energy Sources 22, 851–857 (2000)

Shaw, M.: Feedstock and Process Variables Influencing Biomass Densification. M.Sc. Thesis. Department Agricultural Bioresource Engineering, University of Saskatchewan, Saskatoon, Canada (2008)

Holm, J.K., Henriksen, U.B., Hustad, J.E., Sorensen, L.H.: Toward an understanding of controlling parameters in softwood and hardwood pellets production. Energy Fuels 20, 2686–2694 (2006)

Mani, S., Tabil, L.G., Sokhansanj, S.: Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 30, 648–654 (2006)

Rhén, C., Gref, R., Sjöström, M., Wästerlund, I.: Effects of raw material moisture content, densification pressure and temperature on some properties of Norway spruce pellets. Fuel Process. Technol. 87, 11–16 (2005)

Lehtikangas, P.: Quality properties of pelletised saw dust, logging residues and bark. Biomass Bioenergy 20, 351–360 (2001)

Gilbert, P., Ryu, C., Sharifi, V., Swithenbank, J.: Effect of process parameters on pelletisation of herbaceous crops. Fuel 88, 1491–1497 (2009)

Van Loo, S., Koppejan, J.: The Handbook of Biomass Combustion and Co-firing. Earthscan, London, Washington DC (2008)

Obernberger, I., Thek, G.: The Pellet Handbook: The Production and Thermal Utilisation of Pellets. Earthscan, London (2010)

Tabil, L., Sokhansanj, S.: Process conditions affecting the physical quality of alfalfa pellets. Appl. Eng. Agric. 12(3), 345–350 (1996)

Stelte, W., Holm, J.K., Sanadi, A.R., Barsberg, S., Ahrenfeldt, J., Henriksen, U.B.: Fuel pellets from biomass: the importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 90, 3285–3290 (2011)

Prins, M.J.: Thermodynamic Analysis of Biomass Gasification and Torrefaction. Ph.D. Thesis, Eindhoven Technical University, The Netherlands (2005)

Brás, A.M., Miranda, F., Hipólito, L., Dias, L.S.: Biomassa e produção de energia. http://www.draedm.minagricultura.pt/draedm/centrodocumentacao/revista_pdf/06.Biomassa_AldaBr%C3%A1s.pdf [29/09/2010]

ASTM: Standard Test Methods for Proximate Analysis of Wood Charcoal. ASTM, USA (1982)

CEN/TS 14918: Solid Biofuels—Method for the Determination of Calorific Value. British Standards, p.66 (2005)

CEN/TS 14774-2: Solid Biofuels—Methods for the Determination of Moisture Content. Oven Dry Method. Part 2: Total Moisture. Simplified Method, British Standards, p.12 (2004)

CEN/TS 14775: Solid Biofuels—Method for the Determination of Ash Content. British Standards, p. 12 (2004)

CEN/TS 15210: Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes. Part 2: Briquettes. British Standards, p. 12 (2005)

Temmerman, M., Rabier, F., Jensen, P.D., Hartmann, H., Böhm, T.: Comparative study of durability test methods for pellets and briquettes. Biomass Bioenergy 30, 964–972 (2006)

Obernberger, I., Thek, G.: Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behaviour. Biomass Bioenergy 27, 653–669 (2004)

CENT/TS 15290: Solid Biofuels—Determination of Major Elements. British Standards, p.16 (2006)

Bergström, D., Israelsson, S., Öhman, M., Dahlqvist, S., Grefa, R., Boman, Ch., Wästerlund, I.: Effects of raw material particle size distribution on the characteristics of Scots pine sawdust fuel pellets. Fuel Process. Technol. 89, 1324–1329 (2008)

Larson, T.V., Koenig, J.Q.: Wood smoke emissions and non-cancer respiratory effects. Ann. Rev. Pub. Health 15, 133–156 (1994)

Purohit, P., Tripathi, A.K., Kandpal, T.Ch.: Energetics of coal substitution by briquettes of agricultural residues. Energy 3, 1321–1323 (2006)

Lehtikangas, P.: Storage effects on pelletised sawdust, logging residues and bark. Biomass Bioenergy 19, 287–293 (2000)

O¨NORM M 7135: Compressed Wood or Compressed Bark in Natural State, Pellets and Briquettes, Requirements and Test Specifications. Österreichisches Normungsinstitut, Vienna, Austria (2000)

DIN 51731: Testing of Solid Fuels e Compressed Untreated Wood, Requirements and Testing. Deutsches Institut für Normung, Berlin, Germany (1996)

Peksa-Blanchard, M., Dolzan, P., Grassi, A., Heinimö, J., Junginger, M., Ranta, T., et al.: Global wood pellets markets and industry: policy drivers, market status and raw material potential. IEA Bioenergy Task 2007;40 [Online]. Avaiable at http://igitur-archive.library.uu.nl/chem/2008-0424-200431/UUindex.html[25/02/ 2012]

Uslu, A., Faaij, A.P.C., Bergman, P.C.A.: Pre-treatment technologies and their effect on international bioenergy supply chain logistics. Techno-economic evaluation of torrefaction, fast pyrolysis and pelletisation. Energy 33, 1206–1223 (2008)

Öhman, M., Boman, C., Hedman, H., Nordin, A., Boström, D.: Slagging tendencies of wood pellet ash during combustion in residential pellet burners. Biomass Bioenergy 2004(27), 585–596 (2004)

Saastamoinen, J.J., Martti, J., Linna, L.: Simultaneous pyrolysis and char combustion. Fuel 72, 599–609 (1993)

Mansaray, K.G., Ghaly, A.E.: Physical and thermochemical properties of rice husk. Energy Sources 19, 989–1004 (1997)

Felfli, F.F.: Torrefaction Biomass, Technical Feasibility and Market Potential. Ph.D. Thesis. Faculty of Mechanical Engineering, State University of Campinas, Brazil (2003) (in Portuguese)

Felfli, F.F., Luengo, C.A., Soler, P.B.: Torrefaction biomass: features, applications and perspectives. In; Proceedings of the 3rd Meeting of Energy in Rural Areas, Campinas, SP, Brazil (2000)

Bergman, P.C.A., Boersma, A.R., Zwart, R.W.R., Kiel, J.H.A.: Torrefaction for Biomass Co-firing in Existing Coal-Fired Power Stations: Biocoal. ECN-C-05–013, Energy Research Center of the Netherlands, the Netherlands (2005)

Acknowledgments

This research is part of the results obtained in PTDC/AGR-AAM/104288/2008 project funded by the Foundation of Science and Technology, Portugal and support of the COMPETE.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mustelier, N.L., Almeida, M.F., Cavalheiro, J. et al. Evaluation of Pellets Produced with Undergrowth to be Used as Biofuel. Waste Biomass Valor 3, 285–294 (2012). https://doi.org/10.1007/s12649-012-9127-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-012-9127-5