Abstract

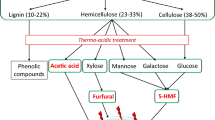

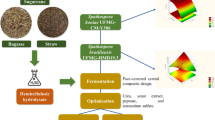

Ionic liquid (IL) based pretreatment of lignocellulosic biomass for facilitating efficient enzymatic saccharification has emerged as an environmentally benign approach that offers several advantages over conventional strategies. However, residues of ionic liquid left in the pretreated biomass may cause inactivation of saccharifying enzymes thus, necessitating the requirement of ionic liquid-stable enzymes. Cost-effective production of industrial enzymes is always desired to enhance the overall process economy. Current study reports IL-stable cellulase production from a newly isolated bacterium Bacillus subtilis G2. Design of experiment (DoE) based on response surface methodology was used in sequential manner for optimizing cultural and environmental variables to enhance cellulase production by 2.66-fold. IL-stable cellulase was used for saccharification of IL-pretreated pine needle biomass (PNB) with 1-ethyl-3-methylimidazolium methanesulfonate in a consolidated single pot process i.e. one pot consolidated bioprocess (OPCB). The saccharification efficiency of 23.57 % was observed under OPCB. The hydrolsate obtained was fermented by dual culture of yeast i.e. Saccharomyces cereviasie NCIM 3078 and Pichia stipitis NCIM 3497, and a yield of 0.092 g ethanol/g of PNB was obtained with fermentation efficiency of 25.62 %. This study is first ever where-in IL-stable cellulase production is accomplished using agroindustrial residues by employing DoE, and assessed for its application potential under OPCB for saccharification of IL-pretreated PNB. IL-stable cellulases would not only preclude expensive washing step following IL-pretreatment of biomass, but their application in a consolidated single pot process (OPCB) offers numerous technoeconomic advantages over conventional multi pot processes.

Graphical Abstract

Production of ionic liquid (IL) tolerant cellulase from Bacillus subtilis G2 was enhanced by 2.66-fold using response surface methodology. Cellulase was assessed for its saccharification potential on IL-pretreated pine needle biomass under one pot consolidated bioprocess, and the hydrolysate was fermented to ethanol using Saccharomyces cereviasie and Pichia stipitis.

Similar content being viewed by others

References

Oleskowicz-Popiel, P., Klein-Marcuschamer, D., Simmons, B.A., Blanch, H.W.: Lignocellulosic ethanol production without enzymes–technoeconomic analysis of ionic liquid pretreatment followed by acidolysis. Bioresour. Technol. 158, 294–299 (2014)

Salehi Jouzani, G., Taherzadeh, M.J.: Advances in consolidated bioprocessing systems for bioethanol and butanol production from biomass: a comprehensive review. Biofuel Res. J. 5, 152–195 (2015)

Sharma, M., Bajaj, B.K.: Cellulase production from Bacillus subtilis MS 54 and its potential for saccharification of biphasic-acid-pretreated rice straw. J. Biobased Mater. Bioenerg 8, 449–456 (2014)

Nanda, S., Dalai, A.K., Kozinski, J.A.: Butanol and ethanol production from lignocellulosic feedstock: biomass pretreatment and bioconversion. Energy Sci. Eng. 23, 138–148 (2014)

Gupta, M., Sharma, M., Singh, S., Gupta, P., Bajaj, B.K.: Enhanced production of cellulase from Bacillus licheniformis K-3 with poteintial saccharification of rice straw. Energy Technol. 3, 216–224 (2015)

Singh, S., Sambyal, M., Vaid, S., Singh, P., Bajaj, B.K.: Process optimization for production of ionic liquid resistant, thermostable and broad range pH-stable cellulase from Bacillus subtilis I-2. Biocatal. Biotransform. 33, 224–233 (2015)

Konda, N.M., Shi, J., Singh, S., Blanch, H.W., Simmons, B.A., Klein-Marcuschamer, D.: Understanding cost drivers and economic potential of two variants of ionic liquid pretreatment for cellulosic biofuel production. Biotechnol. Biofuel 7, 86–96 (2014)

Xu, J., Wang, X., Hu, L., Xia, J., Wu, Z., Xu, N., Dai, B., Wu, B.: A novel ionic liquid-tolerant Fusarium oxysporum BN secreting ionic liquid stable cellulase: consolidated bioprocessing of pretreated lignocellulose containing residual ionic liquid. Bioresour. Technol. 181, 18–25 (2014)

Raddadi, N., Cherif, A., Daffonchio, D., Fava, F.: Halo-alkalitolerant and thermostable cellulases with improved tolerance to ionic liquids and organic solvents from Paenibacillus tarimensis isolated from the Chott El Fejej, Sahara desert, Tunisia. Bioresour. Technol. 150, 121–128 (2013)

Trivedi, N., Gupta, V., Reddy, C.R.K., Jha, B.: Detection of ionic liquid stable cellulase produced by the marine bacterium Pseudoalteromonas sp. isolated from brown alga Sargassum polycystum C. Agardh. Bioresour. Technol. 132, 313–319 (2013)

Ilmberger, N., Meske, D., Juergensen, J., Schulte, M., Barthen, P., Rabausch, U., Angelov, A., Mientus, M., Liebl, W., Schmitz, R.A.: Metagenomic cellulases highly tolerant towards the presence of ionic liquids-linking thermostability and halotolerance. Appl. Microbiol. Biotechnol. 95, 135–146 (2012)

Park, J.I., Steen, E.J., Burd, H., Evans, S.S., Redding-Johnson, A.M., Batth, T., Benke, P.I., D’haeseleer, P., Sun, N., Sale, K.L., Keasling, J.D.: A thermophilic ionic liquid-tolerant cellulase cocktail for the production of cellulosic biofuels. PLoS One 7, e37010 (2012)

Parisutham, V., Kim, T.H., Lee, S.K.: Feasibilities of consolidated bioprocessing microbes: from pretreatment to biofuel production. Bioresour. Technol. 161, 431–440 (2014)

Singh, S., Moholkar, V.S., Goyal, A.: Optimization of carboxymethylcellulose production from Bacillus amyloliquefaciens SS35. 3 Biotech. 4, 411–424 (2013)

Gosh, M.K., Gosh, U.K.: Utilization of pine needles as a bed material in solid state fermentation for production of lactic acid by Lactobacillus strains. BioResources 6, 1556–1575 (2011)

Vats, S., Maurya, D.P., Jain, A., Mall, V., Negi, S.: Mathematical model-based optimization of physico-enzymatic hydrolysis of Pinus roxburghii needles for the production of reducing sugars. Indian J. Exp. Biol. 51, 944–953 (2013)

Singh, S., Anu, S.V., Singh, P., Bajaj, B.K.: Physicochemical pretreatment of pine needle biomass by design of experiments approach for efficient enzymatic saccharification. J. Mater. Environ. Sci. 7, 2034–2041 (2016)

Miller, G.L.: Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959)

Singh, S., Bajaj, B.K.: Agroindustrial/forestry residues as substrates for production of thermoactive alkaline protease from Bacillus licheniformis K-3 having multifaceted hydrolytic potential. Waste Biomass Valor. (2016). doi:10.1007/s12649-016-9577-2

Sharma, S., Vaid, S., Bajaj, B.K.: Screening of thermo-alkali stable fungal xylanases for potential industrial applications. Curr. Res. Microbiol. Biotechnol. 3, 536–541 (2015)

Bradford, M.M.: A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Chem. 72, 248–254 (1976)

Gupta, P., Samant, K., Sahu, A.: Isolation of cellulose-degrading bacteria and determination of their cellulolytic potential. Int. J. Microbiol. (2011). doi:10.1155/2012/578925

Vogel, K.P., Dien, B.S., Jung, H.G., Casler, M.D., Masterson, S.D., Mitchell, R.B.: Quantifying actual and theoretical ethanol yields for switchgrass strains using NIRS analyses. Bioenerg Res. 4, 96–110 (2011)

Liang, Y.L., Zhang, Z., Wu, M., Wu, Y., Feng, X.J.: Isolation, screening, and identification of cellulolytic bacteria from natural reserves in the subtropical region of China and optimization of cellulase production by Paenibacillus terrae ME27-1. BioMed Res. Int. (2014). doi:10.1155/2014/512497

Nizamudeen, S., Bajaj, B.K.: A novel thermo-alkalitolerant endoglucanase production using cost-effective agricultural residues as substrates by a newly isolated Bacillus sp. NZ. Food Technol. Biotechnol. 47, 435–440 (2009)

Xu, J., He, B., Wu, B., Wang, B., Wang, C., Hu, L.: An ionic liquid tolerant cellulase derived from chemically polluted microhabitats and its application in in situ saccharification of rice straw. Bioresour. Technol. 157, 166–173 (2014)

Jaishankar, M., Mathew, B.B., Shah, M.S., Murthy, T.P.K., Gowda, K.R.S.: Biosorption of few heavy metal ions using agricultural wastes. J Environ. Pollut. Hum. Health 2, 1–6 (2014)

Bajaj, B.K., Singh, N.P.: Production of xylanase from an alkalitolerant Streptomyces sp. 7b under solid-state fermentation, its purification and characterization. Appl. Biochem. Biotechnol. 162, 1804–1818 (2010)

Gaur, R., Tiwari, S.: Isolation, production, purification and characterization of an organic-solvent-thermostable alkalophilic cellulase from Bacillus vallismortis RG-07. BMC Biotechnol. 15, 19–31 (2015)

Annamalai, N., Rajeshwari, M.V., Elayaraja, S., Balasubramanian, T.: Thermostable, haloalkaline cellulase from Bacillus halodurans CAS 1 by conversion of lignocellulosic wastes. Carbohyd. Polym. 15, 409–415 (2013)

Shi, J., Gladden, J.M., Sathitsuksanoh, N., Kambam, P., Sandoval, L., Mitra, D., Zhang, S., George, A., Singer, S.W., Simmonsa, B.A., Singh, S.: One-pot ionic liquid pretreatment and saccharification of switchgrass. Green Chem. 15, 2579–2589 (2013)

Qing, Q., Hu, R., He, Y., Zhang, Y., Wang, L.: Investigation of a novel acid-catalyzed ionic liquid pretreatment method to improve biomass enzymatic hydrolysis conversion. Appl. Microbiol. Biotechnol. 98, 5275–5286 (2014)

Nasirpour, N., Mousavi, S.M., Shojaosadati, S.A.: A novel surfactant-assisted ionic liquid pretreatment of sugarcane bagasse for enhanced enzymatic hydrolysis. Bioresour. Technol. 169, 33–37 (2014)

An, Y.X., Zong, M.H., Wu, H., Li, N.: Pretreatment of lignocellulosic biomass with renewable cholinium ionic liquids: biomass fractionation, enzymatic digestion and ionic liquid reuse. Bioresour. Technol. 192, 165–171 (2015)

Bahrani, S., Raeissi, S., Sarshar, M.: Experimental investigation of ionic liquid pretreatment of sugarcane bagasse with 1,3-dimethylimadazolium dimethyl phosphate. Bioresour. Technol. 185, 411–415 (2015)

Tanimura, A., Kikukawa, M., Yamaguchi, S., Kishino, S., Ogawa, J., Shima, J.: Direct ethanol production from starch using a natural isolate, Scheffersomyces shehatae: toward consolidated bioprocessing. Sci. Rep. 5, 9593 (2014)

Acknowledgments

Dr. Bijender Kumar Bajaj gratefully acknowledges the Department of Science and Technology (Govt. of India) for financial support (Research Project Ref. SR/SO/BB-66/2007), and Commonwealth Scholarship Commission, UK, for providing Commonwealth Fellowship (INCF-2013-45) for ‘Research Stay’ at Institute of Biological, Environmental and Rural Sciences (IBERS), Aberystwyth University, Aberystwyth, UK. Authors thank the Director, School of Biotechnology, University of Jammu, Jammu, for necessary laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Vaid, S., Bajaj, B.K. Production of Ionic Liquid Tolerant Cellulase from Bacillus subtilis G2 Using Agroindustrial Residues with Application Potential for Saccharification of Biomass Under One Pot Consolidated Bioprocess. Waste Biomass Valor 8, 949–964 (2017). https://doi.org/10.1007/s12649-016-9626-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9626-x