Abstract

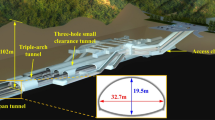

This paper presents a study on the mechanical behavior in a long pipe roof during excavation of a shallow bias highway tunnel in loose deposits. The mechanical parameters of the surrounding soil were obtained by triaxial consolidated-drained shear tests on large reconstituted specimens. Three-dimensional numerical modeling was conducted to simulate the tunnel construction process. Six typical construction stages were simulated to analyze the effects of tunnel support elements, topographic and geological conditions on the mechanical behavior of the pipe roof. The modeling results revealed the variation of force and bending moment distribution in the pipe roof during excavation. Three main conclusions were drawn: (1) for the shallow and asymmetrically loaded tunnel buried in loose deposits, a pipe roof at the entrance can effectively reduce the stresses and asymmetric loading between the tunnel support elements and enhance the tunnel safety during construction; (2) because of asymmetrical stresses, the umbrella arch could shoulder much of the axial force of the pipe roof and the protection arch could reduce the force on the pipe roof effectively; (3) influenced by the asymmetric topography, the maximum force and bending moment in the pipe roof occurred mainly in the upper right tunnel heading. As the stiffness of the retaining wall, protection arch, umbrella arch, and the surrounding loose deposits were different, the force and bending moment distribution in the pipe roof was highly non-uniform during excavation. The simulation results should be significant both for the pipe roof design and the construction of other tunnels in similar geologic conditions.

Similar content being viewed by others

References

Bae GJ, Shin HS, Sicilia C, Choi YG, Lim JJ (2005) Homogenization framework for three-dimensional elastoplastic finite element analysis of a grouted pipe-roofing reinforcement method for tunnelling. Int J Num Anal Met 29(1):1–24

Bi JL, Wang WF, Liu CL (2008) Analysis on parameters of pipe roof advance support installed in portal sections of shallow-buried double-arched tunnels. Tunn Constr 28(4):438–455 (in Chinese)

Hisatake M, Ohno S (2008) Effects of pipe roof supports and the excavation method on the displacements above a tunnel face. Tunn Undergr Space Technol 23(2):120–127

Inokuma A, Inano S (1996) Road tunnels in Japan: deterioration and Countermeasures. Tunn Undergr Space Technol 11(3):305–309

Itasca Consulting Group, Inc (2005) FLAC 3D version 3.0, User’s Manual. Itasca Consulting Group Inc

Jeng FS, Weng MC, Huang TH, Lin ML (2002) Deformational characteristics of weak sandstone and impact to tunnel deformation. Tunn Undergr Space Technol 17(3):263–274

JTG D70-2004 (2010) Code for design of road tunnel. Chin Comm Press, Beijing (in Chinese)

Lee YZ, Schubert W (2008) Determination of the round length for tunnel excavation in weak rock. Tunn Undergr Space Technol 23(3):221–231

Ocak I (2008) Control of surface settlements with umbrella arch method in second stage excavations of Istanbul Metro. Tunn Undergr Space Technol 23(6):674–681

Ozsan A, Basarir H (2003) Support capacity estimation of a diversion tunnel in weak rock. Eng Geol 68(3–4):319–331

Shahrour I, Khoshnoudian F, Sadek M, Mroueh H (2010) Elastoplastic analysis of the seismic response of tunnels in soft soils. Tunn Undergr Space Technol 25(4):478–482

Sharifzadeh M, Tarifard A, Moridi MA (2013) Time-dependent behavior of tunnel lining in weak rock mass based on displacement back analysis method. Tunn Undergr Space Technol 38:348–356

Shi YF, Yang JS, Wang SY (2014) Sub-horizontal reinforcement of weathered granite before tunneling beneath a spillway. Int J Rock Mech Min 72:283–293

SL237-1999 (1999) Specification of soil test. Chin Water Power Press, Beijing (in Chinese)

Song KI, Cho GC, Chang SB, Lee IM (2013) Beam-spring structural analysis for the design of a tunnel pre-reinforcement support system. Int J Rock Mech Min 59:139–150

Tang JS, Liu SY, Tong LY (2008) The minimum safe net distance between large span expressway tunnels. China Civ Eng J 41(12):79–84 (in Chinese)

Vermeer PA, Borst DR (1984) Non-associated plasticity for soils, concrete and rock. Heron 29(3):7–8

Wang TT (2010) Characterizing crack patterns on tunnel linings associated with shear deformation induced by instability of neighboring slopes. Eng Geol 115(1):80–95

Wang ZC, Wong RCK, Li SC, Qiao LP (2012) Finite element analysis of long-term surface settlement above a shallow tunnel in soft ground. Tunn Undergr Space Technol 30:85–92

Weng MC, Tsai LS, Liao CY, Jeng FS (2010) Numerical modeling of tunnel excavation in weak sandstone using a time-dependent anisotropic degradation model. Tunn Undergr Space Technol 25(4):397–406

Xiao JZ, Dai FC, Wei YQ, Min H, Xu C, Tu XB, Wang ML (2014) Cracking mechanism of secondary lining for a shallow and asymmetrically-loaded tunnel in loose deposits. Tunn Undergr Space Technol 43:232–240

Xiao JZ, Dai FC, Wei YQ, Xing YC, Cai H, Xu C (2015) Comparative analysis of excavation schemes for a tunnel constructed through loose deposits. J Perform Constr Facil. doi:10.1061/(ASCE)CF.1943-5509.0000813

Yoo C (2002) Finite-element analysis of tunnel face reinforced by longitudinal pipes. Comput Geotech 29(1):73–94

Yoo C, Shin HK (2003) Deformation behaviour of tunnel face reinforced with longitudinal pipes-laboratory and numerical investigation. Tunn Undergr Space Technol 18(4):303–319

Zhang ZQ, Li HY, Liu HY, Li GJ, Shi XQ (2014) Load transferring mechanism of pipe umbrella support in shallow-buried tunnels. Tunn Undergr Space Technol 43:213–221

Zhu HH, Ye B, Cai YC, Zhang F (2013) An elasto-viscoplastic model for soft rock around tunnels considering overconsolidation and structure effects. Comput Geotech 50:6–16

Acknowledgments

This research was supported by the National Basic Research Program of China (973 Program, Grant No. 2014CB047004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, J.Z., Dai, F.C., Wei, Y.Q. et al. Analysis of mechanical behavior in a pipe roof during excavation of a shallow bias tunnel in loose deposits. Environ Earth Sci 75, 293 (2016). https://doi.org/10.1007/s12665-015-5176-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-015-5176-y