Abstract

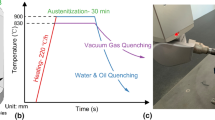

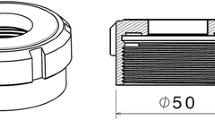

Distortion while quenching steel is a commonly found problem in industrial practice. This issue arises from the combined effect of thermal contraction and martensite transformation stresses. This problem may be exacerbated in components with long geometries. This work presents the results of a numerical and experimental investigation that assessed the effect of both the austenite grain size (AGS) of three sizes 8, 9 and 10 ASTM, and the immersion route on the distortion of a long component of SAE 5160 steel during oil quenching. The transformation kinetics were calculated using JMatPro and were validated by quench dilatometry. A three-dimensional finite element model was developed in Deform 3D. This model was then validated using thermocouple data. Results showed that the distortion was minimized when the long component was dipped sideways in the quenching medium instead of immersing the component from the distal ends when the AGS was 8 ASTM.

Similar content being viewed by others

References

Jung M, Kang M, and Lee Y K, Acta Mater 60 (2012) 525.

Lee S J, and Lee Y K, Acta Mater 56 (2008) 1482.

Şimşir C, and Gür C H, J Mater Process Technol 207 (2008) 211.

Da Silva A D, Pedrosa T A, Gonzalez-Mendez J L, Jiang X, Cetlin P R, and Altan T, Mater Des 42 (2012) 55.

Huang D, Arimoto K, Lee K, and Lambert D, Prediction of Quench Distortion on Steel Shaft with Keyway by Computer Simulation, Heat Treating Conference Exposition, (2000) 1.

Woodard P R, Chandrasekar S, and Yang H T Y, Metall Mater Trans B 30 (1999) 815.

Guo Z, Saunders N, Miodownik P, and Schillé J P, Int J Microstruct Mater Prop 4 (2009) 187.

Ouchi C, ISIJ Int 41 (2001) 542.

Babu K, Adv Mat Res 488–489 (2012) 353.

Yaakoubi M, Kchaou M, and Dammak K, Comput Mater Sci 68 (2013) 297.

Barford J, and Owen W S, Met Sci Heat Treat 4 (1962) 359.

Matsuzaki A, and Bhadeshia H K D H, Mater Sci Technol 15 (1999) 518.

Van Bohemen S M C, Metall Mater Trans A 41 (2010) 285.

Denis S, Sjöström S, and Simon A, Metall Trans A 18 (1987) 1203.

Huang J, Ye X, Gu J, Chen X, and Xu Z, Mater Sci Eng A 532 (2012) 190.

Denis S, Gautier E, Simon A, and Beck G, Mater Sci Technol 1 (1985) 805.

Inoue T, Ju D Y, and Arimoto K, in Proceedings of International Conference on Quenching and Control of Distortion, ASM, Ohio, 1 (1992), p 205.

Metals Handbook Materials Selection and Design, ASM International, Ohio 20 (1997) 774.

Sugianto A, Narazaki M, Kogawara M, and Shirayori A, J Mater Process Technol 209 (2009) 4627.

Guo Z, Saunders N, and Schillé J P, Modelling phase transformation and materials properties critical to simulation of heat treatment distortion in steels, Sente Software Ltd, London (2008).

Amey C M, Huang H, and Rivera-Diaz-del-Castillo P E J, Mater Des 35 (2012) 66.

Nallathambi A K, Kayamak Y, Specht E, and Bertram A, J Mater Process Technol 210 (2010) 204.

Garcia-Pastor F A, Lopez-Garcia R D, Alfaro-Lopez E, and Castro-Roman M J, in Proc of XXI International Materials Research Congress, ASM, Mexico, 1485 (2012), p 29.

Garcia-Pastor F A, Lopez-Garcia R D, and Castro-Roman M J, in Proc of 5th International Conference on Thermal Process Modelling, ASM, Ohio, (2014), p 14.

Hasan H S, and Peet M J, Int Commun Heat Mass Transfer 39 (2012) 1519.

Cheng H, Xie J, and Li J, Comput Mater Sci 29 (2004) 453.

Cheng M, Cheng J, Yuan S Q, and Zhao F, Acta Metall Sin 10 (1997) 479.

Huiping L, Guoqun Z, Lianfang H, and Yue M, Measurement 41 (2008) 676.

Sedighi M, and McMahon C A, J Eng Manuf 241 (2000) 555.

Heming C, Xieqing H, and Jianbin X, J Mater Process Technol 138 (2003) 399.

Gür C H, and Tekkaya A E, Mater Sci Eng A 319 (2001) 164.

Polyakov A A, Met Sci Heat Treat 37 (1995) 324.

Mackerle J, Comput Mater Sci 27 (2003) 313.

Gür C H, and Pan J, Handbook of Thermal Process Modeling of Steel, CRC Press, New York (2009).

Şimşir C, and Gür C H, Comput Mater Sci 44 (2008) 588.

Kang S H, and Im Y T, Int J Mech Sci 49 (2007) 423.

Li Z, Grandhi F V, and Srinivasan R, J Mater Process Tech 172 (2006) 249.

Liu C, Ju D Y, and Inoue T, ISIJ Int 42 (2002) 1125.

Beck J V, User´s Manual for CONTA Program for Calculating Surface Heat Fluxes from Transient Temperatures Inside Solids, Report SAND83-7134, Michigan State University, USA (1983) 1.

Johnson A W, and Mehl R F, Trans AIME 135 (1939) 416.

Avrami M, and Chem J, Phys 7 (1939) 1103.

Koistinen D P, and Marburger R F, Acta Metall 7 (1939) 59.

Scientific Forming Technologies Corporation, Columbus Ohio, DEFORM User´s Manual, Version 6.1 (2007).

Surrey Technology Center United Kingdom, Sente Software Ltd, JMatPro, Version.

Acknowledgments

The authors acknowledge the Mexican Science and Technology Council (Conacyt) for supporting Mr. López-García during his Ph.D. studies at Cinvestav Saltillo. The authors especially thank San Luis Rassini’s personnel, who kindly provided their facilities to perform the heat transfer coefficient measurements.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Lopez-Garcia, R.D., Garcia-Pastor, F.A., Castro-Roman, M.J. et al. Effect of Immersion Routes on the Quenching Distortion of a Long Steel Component Using a Finite Element Model. Trans Indian Inst Met 69, 1645–1656 (2016). https://doi.org/10.1007/s12666-015-0738-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0738-y