Abstract

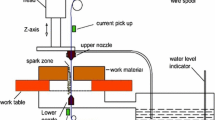

Wire electric discharge machining (WEDM) is a newly emerging non-traditional technology for machining MMCs. In the present study, an attempt has been made to investigate the effect of WEDM parameters such as pulse on time, pulse off time, peak current, spark gap voltage, wire feed rate and wire tension on the surface roughness height (Ra) during WEDM of particulate silicon carbide aluminum metal matrix composites (Al/SiC-MMC). The RSM based Box–Behnken design is employed for experimental investigation. Utilized the acquired results, a quadratic regression model for surface roughness height (Ra) has been developed. An attempt has been made to optimize the process parameters for surface roughness height (Ra). To validate, confirmation experiments have been carried out and predicted results have been found to be in good agreement with experimental findings. The surface morphology of machined surfaces has also been studied using scanning electron microscope. Various surface defects and their possible reasons have been discussed.

Similar content being viewed by others

References

Chawla K K, Composite Materials Science and Engineering, 2nd ed. Springer, New York (1998).

Manna A, and Bhattacharayya B, Int J Adv Manuf Technol 25 (2005) 850.

Bhardwaj B, Kumar R, and Singh P K, Trans Indian Inst Met (2013). doi:10.1007/s12666-013-0346-7.

Tosun N, and Cogun C, J Mater Process Technol 134 (2003) 273.

Yan B H, and Tsai H C, Int J Mach Tools Manuf 45 (2005) 251.

Patil N G, and Brahmankar P K, Int J Adv Manuf Technol 48 (2010) 537.

Satish K D, Kanthababu M, and Vajjiravelu V, Int J Adv Manuf Technol 56 (2011) 975.

Shandilya P J, Jain P K, and Jain N K., Int J Adv Manuf Technol 61 (2012) 1199.

Rao T B, and Krishna A G, Int J Adv Manuf Technol 73 (2014) 299.

Goswami A, and Kumar J, Eng Sci Technol 17 (2014) 173.

Garg R K, Singh K K, and Sachdeva A, Int J Adv Manuf Technol 50 (2010) 611.

Montgomery D C, Design and Analysis of Experiments, 5th ed. Wiley, New York, pp 451–452 (2001).

Kumar A, Kumar V, and Kumar J, Int J Adv Manuf Technol (2013). doi:10.1007/s00170-013-4861-9.

Technology Manual for Wirecut EDM, 4-axis Sprintcut. Electronica Machine Tools Ltd., Pune, India (2004).

Altpeter F, and Perez R, J Mater Process Technol 149 (2004) 147.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, H., Manna, A. & Kumar, R. Modeling of Process Parameters for Surface Roughness and Analysis of Machined Surface in WEDM of Al/SiC-MMC. Trans Indian Inst Met 71, 231–244 (2018). https://doi.org/10.1007/s12666-017-1159-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1159-x