Abstract

Miscible carbon dioxide (CO2) flooding has been recognized as a promising approach to enhance the recovery of oil reservoirs. However, depending on the injection strategy and rock/fluid characteristics, efficiency of the miscible CO2 flooding varies from reservoir to reservoir. Although, many studies have been carried out to evaluate the performance of the miscible CO2 flooding, a specific strategy which can be strictly followed for a hydrocarbon reservoir has not been established yet. The aim of this study is to assess one of Pakistan’s oil reservoirs for miscible CO2 flooding by applying a modified screening criterion and numerical modeling. As such, the most recent miscible CO2 screening criteria were modified, and a numerical modeling was applied on the prospective reservoir. Based on the results obtained, South oil reservoir (S3) is chosen for a detailed assessment of miscible CO2 flooding. It was also found that implementation of CO2 water-alternating gas (CO2-WAG) injection at early stages of production can increase the production life of the reservoir.

Similar content being viewed by others

Introduction

Major oil reservoirs around the globe have an average recovery factor of 20–40% (International 2006; Sandrea 2007). As such, their complete development often requires secondary recovery (injection of gas or water), and tertiary/enhanced oil recovery (EOR) methods (injection of miscible/immiscible fluids, chemical or thermal) (Orr et al. 1982). Unlike the secondary methods, which are known as physical processes, in the tertiary recovery, microscopic displacement and macroscopic sweep efficiency are improved by oil swelling, variation of interfacial tension (IFT), oil viscosity and wettability (Bayat et al. 2016; Brashear and Kuuskraa 1978; Sun et al. 2017). The most common EOR methods were established in the early 1970s (Muggeridge et al. 2014) and are further classified into gas, chemical and thermal technologies. Table 1 summarizes methods, phenomenon and challenges of different EOR technologies (Alvarado and Manrique 2010; Ayatollahi and Zerafat 2012; Kong and Ohadi 2010; Silva et al. 2007; Souza et al. 2005; Thomas 2008).

Among these three, the gas technology using CO2 is perhaps the best method as it helps to achieve the minimum miscible pressure (MMP)—the lowest pressure for CO2 phase to reach the multiple contact miscibility (MCM) under dynamic conditions (Bachu 2016; Gao et al. 2013). As such, CO2 can be applied for miscible EOR or immiscible EOR operation depending on the MMP (Gao et al. 2013).

To optimize recovery of miscible CO2 flooding, continuous CO2 injection (CCO2) and CO2 water-alternating gas (CO2-WAG) injection are often used as well-known injection strategies (Caudle and Dyes 1958). There have been many studies indicating the application of CCO2 or CO2-WAG. For instance, Caudle and Dyes (1958) carried out an experimental investigation and reported that the CO2-WAG process is far better than the CCO2 in terms of cost and performance due to the improvement of displacement. John et al. (1990) carried out numerical modeling for probabilistic cash flow analysis of the miscible CO2 flooding in West Virginia. The results of statistical analysis showed that the CO2-WAG is very suitable and cost effective compared to the CCO2. Heidari et al. (2013) carried out comparison experimentally and numerically between CO2-WAG and CO2 simultaneous water-and-gas (CO2-SWAG) injection. They concluded that the CO2-SWAG enhanced oil production as compared to CO2-WAG in immiscible, near-miscible, and miscible modes of injection, and miscible CO2-SWAG produces more than 74% of original oil in place. Inaloo et al. (2014) performed numerical analysis for one of the Iranian oil reservoirs to determine the optimal production strategy through water flooding, gas injection and WAG. The results obtained indicated that water injection gives a better recovery than gas or WAG injections. In a similar study, Song et al. (2014) numerically investigated the reservoir parameters to evaluate the efficiency of CO2 flooding. It was found that a five-spot injection well pattern is more feasible than inverted nine-spot and seven-spot patterns for CO2-WAG flooding. They also indicated that CO2-WAG flooding is much feasible than CCO2 if cost and tax credit per ton of CO2 are considered. Ahmadi et al. (2016) numerically studied three different CO2 injection scenarios including CO2 injection into an aquifer, CO2 injection into the pay zone, and simultaneous CO2 injection into the aquifer and pay zone. Their study showed that simultaneous CO2 injection into the aquifer and pay zone gives a better oil recovery compared to other scenarios. In a recent study, Jaber and Awang (2017) numerically evaluated the injection strategies during miscible CO2-SWAG injection in a highly heterogeneous clastic reservoir. The results indicated that the CO2-SWAG injection with the ratio of 2:1 provides the maximum oil recovery compared to other injection modes. It seems that the efficiency of miscible CO2 flooding varies from reservoir to reservoir and more studies are required to have a deeper understanding of how miscible CO2 flooding can be successfully employed to improve the recovery in oil reservoirs.

The aim of this paper is to show how oil fields can be screened for miscible CO2 flooding and why an optimum injection strategy must be chosen for production enhancement. A case study from Pakistan is also brought to highlight the application of the methodology proposed.

Preliminary screening

To select a particular EOR technology/method for oil reservoirs, a few essential steps must be taken including: (1) preliminary screening for suitability of EOR method, (2) a comprehensive laboratory and simulation study, (3) pilot tests, and (4) field study (Bourdarot and Ghedan 2011). In this paper, attempts are made to show how these steps must be taken and carefully followed for a successful implementation of miscible CO2 flooding.

Preliminary screening for suitability of EOR

A total number of 15 reservoirs from Pakistan were available for this study with a complete set of data. Preliminary screening of candidate reservoirs was initiated by looking into the technical criteria of EOR methods. Table 2 summarizes different criteria used in this study for the assessment of EOR methods. Looking at this table and analysis of the results indicated that South oil fields, notably the S3, are falling within the range of screening parameters proposed for miscible and immiscible CO2 flooding, whilst North oil fields seem to be suitable for combustion and chemical EOR methods.

Development and implementation of miscible CO2-EOR criteria

There have been many screening criteria proposed to initially chose a reservoir for suitability of miscible CO2 flooding (Al Adasani and Bai 2011; Bachu et al. 2004; Bachu 2016; Brashear and Kuuskraa 1978; Carcoana 1982; Diaz et al. 1996; Fulin 2001; Geffen 1973; Goodlett et al. 1986; Haynes et al. 1976; Iyoho 1978; Klins 1984; McRee 1977; OTA 1978; Rivas et al. 1994; Shaw and Bachu 2002; Taber et al. 1997; Taber 1983), most of which are given in Table 3. The common parameters involved in these criteria are: (1) viscosity and API gravity of oil, (2) reservoir’s oil saturation, (3) temperature and pressure of reservoirs, (4) net pay thickness, and (5) permeability.

There have also been numerous studies reporting the effect of various parameters on miscible CO2 flooding. For instance, Sehbi et al. (2001) reported that phase behavior, diffusion and dispersion are key processes to develop and sustain miscible displacement in a CO2 flood. It was also stated that a uniform pore geometry and pore structure offer a better microscopic displacement efficiency. Shedid (2009) carried out a series of miscible CO2 flooding by considering various modes of reservoir heterogeneity (i.e., fractured reservoirs with different inclination angles, permeability configurations and the sequence of permeability distributions). The results obtained showed that unfractured reservoirs are better than single-fractured ones to get the good recovery. An oil reservoir with a 30° of inclination angle for a single fracture gives the maximum oil recovery, whilst fractured rocks with a 45° inclination angle offers the lowest recovery. Sahimi (2011) stated that the difference between the viscosity of oil and displacing gas has a strong effect on the efficiency of the miscible displacement. Muggeridge et al. (2014) indicated few limitations for the miscible CO2 flooding such as sensitivity to heterogeneity, poor vertical sweeping efficiency and pressure management. Bikkina et al. (2016) evaluated the effect of reservoir wettability and permeability heterogeneity on the performance of miscible CO2 flooding. They concluded that the oil-wet system is better choice for miscible CO2 flooding compared to the water-wet system. Homogeneous oil-wet core was also found to be favorable for the miscible CO2 flooding. Moreover, heterogeneous water-wet core with a fracture could not be beneficial to have improved oil recovery. Ding et al. (2017) experimentally investigated the effects of reservoir heterogeneity, CO2–oil miscibility, and injection patterns on the oil recovery for the immiscible and miscible flooding. It was found that the recovery of oil is sensitive to heterogeneity and multiple-contact miscible CO2 injections. They also indicated that CO2-WAG is the most suitable after the primary continuous CO2 injection for immiscible CO2 flooding. Considering the above studies, the most comprehensive criterion proposed by Bachu (2016) was modified to screen the oil reservoirs for miscible CO2-EOR operations, as given in Table 4.

Table 5 gives the range of parameters required for a reservoir for an effective CO2-EOR practice. The outcome of the mapping of Pakistani fields’ data into the screening table is very encouraging as it shows that most of the South reservoirs possibly meet the initial screening criteria for CO2-EOR. However, after a thorough discussion with the EOR experts and management of the operating company, S3 was selected based on its larger reservoir size compared to other South oil reservoirs for the full field compositional study for CO2 flooding.

Numerical modeling

Geological background

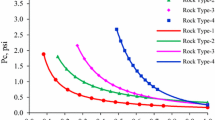

The S3 oil reservoir with an aquifer in its bottom has reached the water-flooding stage. At this stage, the production wells are showing a high water cut, natural decline of oil production, and unfavorable recovery. Therefore, improving oil recovery is a matter of concern and CO2 injection is a potential method that can be considered. This oil field is classified into western, main central, eastern and unproductive southeastern blocks. Central block is enriched with oil, but the whole reservoir does not contribute into production. The reservoir model is composed of 18 layers which are subdivided into four producible layers (i.e., 1–4, 6–9, 11–15, and 17–18). Compared to bottom layers, two sections of 1–4 and 6–9 are enriched by hydrocarbons. There are three injection wells from which one injection well has been used as the water injection well. The oil produced from this field has different quality ranging from 37° API to 44° API in western and central blocks and 49° API in eastern block. Porosity varies from 9.5 to 18% in the main central horst. Irreducible water saturation (Swir) is estimated to be around 26.1% based on the capillary pressure data and close to 17.5% according to the water–oil relative permeability data. Moreover, residual oil saturation in the water–oil system (Sorw) is changing from 15 to 30% with an average of 22%.

Data sources and model setup

A reservoir model was built for the purpose of this study consisting of 43,200 grid cells with 30, 80 and 18 grids in X-, Y- and Z-directions, respectively. The reservoir with a total number of 18 layers with the thickness of 240 m, an initial reservoir pressure of 3238 psia, oil saturation of 80% and connate water saturation of 20% was considered. The bubble point pressure obtained from the pressure–volume–temperature (PVT) analysis was set to be 1722 psia at 246 °F. An aquifer was put at the bottom of the reservoir using the Carter–Tracy analytical model. Characterization of the reservoir fluid was done before simulating the phase behavior. Component characterization including the lumping and splitting theory was modeled to observe the laboratory phase behavior so that a representative PVT fluid model could be developed based on a reliable match between the observed and the calculated data. Widely accepted three-parameter Peng–Robinson (PR) Equation of State (EoS) (O’Reilly 2009) was calibrated/regressed to represent the fluid model in the compositional simulation. Initial bottom-hole sample data are listed in Table 6.

In the very first step, fluid systems (mixtures) represented by pure and pseudocomponents (Whitson and Brulé 2000) were initially assessed for critical volume, critical temperature, critical pressure, acentric factor, volume shift parameter, and binary interaction coefficients. The observed and experimental data were compared by regression for tuning the properties for compositional modeling and to accurately estimate the fluid phase behavior as well as the vapor liquid equilibria (VLE). To decrease the simulation time, C1–C3 and multiple isomers were clustered into a single or pseudocomponent, and as such the reservoir fluid was represented by seven components consisting of CO2 and six pseudocomponents in the PVT analysis. The mole fractions and molecular weights of these components are provided in Table 7.

The observed and experimental data accurately matched for saturation pressure are shown in Fig. 1 while oil relative volume, relative volume, gas gravity and gas z-factor are depicted in Fig. 2. Match of z-factor is not as good as other matches included. It was possible to have relatively better match of z-factor. In that case, other matches such as saturation pressure, oil relative volume could have bad match. Upon successful validation, the fluid model was considered as an input in different phases for history matching, predictive and optimization phases.

In the absence of slim tube apparatus, three options are available to estimate MMP: correlation, PVTi module, and Eclipse compositional to simulate the slim tube experiment. Hence, MMP of the reservoir fluid was estimated by reliable compositional modeling approach. Results of slim tube compositional mdoeling are plotted as shown in Fig. 3. As it can be seen in Fig. 3, the intersection lines for the low and high recovery factors give MMP value of 1325 psia at 246 °F. If MMP is less than bubble point pressure, then the CO2 MMP is set equal to the bubble point pressure (Goodrich 1980; Klins 1984; Khazam et al. 2016). Furthermore, CO2 injection pressure for the case under study is even more than the bubble point pressure.

Simulation results and discussion

This section was divided into three connected parts. In the first part, “Do_Nothing” primary recovery forecast is presented that considers no fluid injection. The second part brings the results of the optimum operating conditions for CCO2 and CO2-WAG. The last and the third part provides a comparison among the primary recovery, CCO2 and CO2-WAG scenarios.

Primary recovery and forecast

After calibration of the PVT model, the model was run for history matching by considering the production strategy followed by the operator. A good history match between the actual field oil production rate history (FOPRH) and observed field oil production rate (FOPR) of more than 23 years was achieved as shown in Fig. 4. The average reservoir pressure of 1801 psia was then found which was still more than the bubble point pressure at the end of the history match period. Figure 5a, b displays initial fluid saturations and well locations, respectively. In this figure, red colored wells are production wells and white colored wells are showing shut-in wells. Oil rate was set as a constraint to shut the low-productivity wells, and as such half of the producer wells were shut-in during the prediction phase. During the primary recovery phase, water was flooded in the water zone after 14 years of production by converting two down-dip central block producers (one is in Northern part and other in Southern part) into injectors. Water injection with a rate of 860 stock tank barrel per day (STB/D) was performed for 39 months. The injected water pushed the oil–water contact (OWC) away from northern part of the field which can be seen by comparing Fig. 5c and d.

Upon history matching, the recovery was forcasted for the next 20 years by setting only six wells on the production with eight wells closed. As mentioned earlier, history matching was carried out by following the production strategy of the operating company; therefore, totally eight wells were kept close due to a very high pressure drop and low productivity. However, a number of oil companies shut in oil and gas production wells due to low prices and lease issue (http://www.fhoa.ca). However, only three wells were open at the end of 20 years of production forecast. The results obtained from field oil recovery efficiency as OOIPinitial − OOIPnow/OOIPinitial (FOE), cumulative field oil production (FOPT) in stock tank barrel (STB), field oil production rate (FOPR) in STB/D, filed reservoir pressure (FPR) in psia, field gas production rate (FGPR) in 1000 standard cubic feet per day (MSCF/D), and field instantaneous water cut (FWCT) in percentage are shown in Fig. 6a, b.

The results of the primary recovery forecast did not seem favorable which might be due to the low aquifer support at the edge water drive reservoir. Having said that, the oil recovery during the forecasted period was found to be 20% less than the half of the recovery by the end of the history period which confirms the volumetric behavior. Water cut is not, however, significant at the end of the forecasted period. The effect of water injection for 16–19 years was observed on FPR. After 20 years of forecasting, the field oil production rate was 212 STB/D which is not high enough to keep the reservoir at the primary recovery stage. Table 8 presents the statistical results at the end of history match and forecast period which strongly point out the essential of implementing oil recovery enhancement.

Optimum constraints for CCO2 and CO2-WAG injections

In this section, the importance of well locations in a CCO2 operation is presented. The WAG ratio and well completion strategy, in different layers for CO2-WAG, are also discussed by numerical modeling using the data given in Table 9.

To assess the importance of injector well’s location on a dipping central block, an injector was considered on two different locations: one up-dip and the other down-dip (see Fig. 7a, b). The injector well (solid red with a red circle around it) was in the center and completed in the top four layers. Red colored wells are production wells and white colored wells are showing shut-in wells. All production wells were set up-dip except the one. Production wells were displayed by solid red with a red circle around them while the white circle with an arrow represented the shut-in wells. The simulation results for the FOPT, FPR, FOPR and FGPR for both locations are given in Table 10.

Obtained results showed that location 2 (up-dip) offers a better oil production as compared to location 1 (down-dip), but the breakthrough occurs before 2 years. It was also found that the reservoir pressure increases during the down-dip CO2 injection. Comparatively, the CCO2 injection offers a better result than the primary recovery. Thus, an up-dip CO2 injector might be the best choice when it comes to selecting the better location.

Caudle and Dyes (1958) recommended to employ SWAG to mitigate the mobility contrast, but the issue of gravity segregation could be raised. Therefore, the CO2-WAG mode was considered rather than SWAG. However, the CO2-WAG process is influenced by reservoir heterogeneity, wettability, miscibility condition, fluid properties, and WAG ratio (Kyrylovych 2012). Thus, five CO2-WAG ratios were considered to pick the optimal one based on the analysis of FOE, FOPR, FPR, FGPR and FWCT. These ratios were 1:1, 1:2, 1:3, 2:1 and 3:1 with water as the first fluid. The well locations for all CO2-WAG scenarios (see Fig. 7) were the same as that of the CCO2 up-dip case. The comparison indicated that the CO2-WAG ratio of 1:2 is an optimal ratio, as presented in Table 11.

To determine a suitable well completion, the CO2-WAG ratio of 1:2 was considered by considering the top four layers and top nine layers (i.e., excluding the non-reservoir layers) with the results presented in Table 12. Comparatively, both completion schemes had similar recovery, water cut, and rate. On top of that, the FPR was found to be above the bubble point pressure which indicated that the top four layers must be chosen for recovery optimization.

Optimized field oil recovery

To evaluate the scenario of an optimized recovery in the reservoir understudy, in terms of a suitable recovery phase (i.e., Do_Nothing for primary, while CCO2, and CO2-WAG for tertiary), three models were run. The well locations for producers and injector were similar to that of CCO2 case. The run details of the models are given in Table 13.

The field was put on production for 23 years and forecasting the performance was made for the next 20 years. Figure 8a shows the FOE for all three cases. As it is shown in Fig. 8, it seems that the recovery performance of both CCO2 and CO2-WAG cases is more promising than the primary recovery for the first 6 years. The CO2-WAG model is then resulting in a favorable recovery which is twofold better than Do_Nothing and CCO2 cases. Figure 8b compares the FOPR of different recovery phases. Likewise, the overall performance of CO2-WAG is more favorable than CCO2 and Do_Nothing. FPR versus time by various processes is shown in Fig. 8c.

It is observed that there is a depletion mechanism under the primary recovery phase (Do_Nothing). The pressure drop of 225 psi and a total pressure of 1576 psia were observed at the end of the forecasting period. It seems from the pressure trends that CO2 injection process slightly contributes to stabilizing the pressure, and as such the reservoir pressure in the forecasting period is following the same trend as that of the Do_Nothing case. A pressure drop of 172 psi and a total pressure of 1629 psia were observed at the end of forecasting period. On the contrary, the CO2-WAG process was found to be a successful injection strategy to maintain the field pressure at 1830 psi at the end of the forecasting period. These results are aligned with the performance of CO2-WAG published earlier by Caudle and Dyes (1958) and Mousavifar et al. (2012). The field gas oil ratios (FGOR) in MSCF/STB of all three cases are plotted in Fig. 8d.

It is interesting to see high and elevated gas oil ratios (GOR) in the field by the CO2 injection compared to other two cases, which could be due to the position of well locations. The CO2-WAG injection, on the other hand, was offering an acceptable FGOR by enhancing the frontal profile via reducing channeling, gravity override, and relative permeability to gas. In the beginning of the simulation (at 24 years), the water cut was negligible and close to 1% as shown in Fig. 8e.

Form Fig. 8e, it can be concluded that the FWCT by the primary (Do_Nothing) process gradually increases to almost 0.18 and then started to decrease with the same rate until the value of 0.03 is reached at the end of forecasting period. The trend of the FWCT in of the CCO2 was like Do_Nothing case between 24 and 35 years, but its decline rate was much slower, reaching 0.13 at the end of simulation run. The FWCT in the CO2-WAG case increased at a higher rate compared to the other two cases. However, it gave a manageable FWCT level during the forecasting period, thereby not affecting the superior recovery performance of the process. Table 14 compares simulated vectors of all three cases at the end of forecasting period (20 years). By taking this comparison into consideration, the CO2-WAG process was technically found highly suitable to enhance the recovery compared to other two cases.

Conclusion

Oil reservoirs have a naturally low recovery factor. The miscible CO2 displacement mechanism is one of the methods in this scenario which can assist to improve the recovery significantly. Preliminary screening for CO2-EOR is an essential step to determine a suitable oil reservoir for a detailed assessment. However, wettability, heterogeneity and permeability configurations are important parameters that should be included in the screening criteria of miscible CO2 flooding. The S3 reservoir was found to be a potential candidate based on the updated screening criteria. Numerical modeling of injection strategy for miscible CO2 flooding shows that the recovery performance of CCO2 and CO2-WAG processes is far better than the primary recovery. Particularly, the CO2-WAG process with an optimum injection well completion and CO2-WAG ratio was technically the most successful method to increase the incremental recovery by more than two times compared to the primary recovery and continuous injection scenarios.

References

AER, 2014. Commingling, Available from: http://www.aer.ca/rules-and-regulations/by-topic/commingling (accessed 02.12.14). Alberta Energy Regulator

Ahmadi MA, Pouladi B, Barghi T (2016) Numerical modeling of CO2 injection scenarios in petroleum reservoirs: application to CO2 sequestration and EOR. J Nat Gas Sci Eng 30:38–49

Al Adasani A, Bai B (2011) Analysis of EOR projects and updated screening criteria. J Petrol Sci Eng 79(1):10–24

Alvarado V, Manrique E (2010) Enhanced oil recovery: an update review. Energies 3(9):1529–1575

Ayatollahi S, Zerafat MM (2012) Nanotechnology-assisted EOR techniques: new solutions to old challenges. SPE international oilfield nanotechnology conference and exhibition, 12–14 June, Noordwijk, The Netherlands. Society of Petroleum Engineers, pp 1–15, SPE-157094-MS. https://doi.org/10.2118/157094-MS

Bachu S (2016) Identification of oil reservoirs suitable for CO2-EOR and CO2 storage (CCUS) using reserves databases, with application to Alberta, Canada. Int J Greenh Gas Control 44:152–165

Bachu S, Shaw JC, Pearson RM (2004) Estimation of oil recovery and CO2 storage capacity in CO2 EOR incorporating the effect of underlying aquifers. SPE/DOE symposium on improved oil recovery, 17–21 April, Tulsa, Oklahoma. Society of Petroleum Engineers, pp 1–13, SPE-89340-MS. https://doi.org/10.2118/89340-MS

Bachu S, Haug K, Michael K, Buschkuehle B, Adams J (2005) Deep injection of acid gas in Western Canada. Dev Water Sci 52:623–635

Bayat M, Lashkarbolooki M, Hezave AZ, Ayatollahi S (2016) Investigation of gas injection flooding performance as enhanced oil recovery method. J Nat Gas Sci Eng 29:37–45

Bikkina P, Wan J, Kim Y, Kneafsey TJ, Tokunaga TK (2016) Influence of wettability and permeability heterogeneity on miscible CO2 flooding efficiency. Fuel 166:219–226

Bourdarot G, Ghedan SG (2011) Modified EOR screening criteria as applied to a group of offshore carbonate oil reservoirs. SPE reservoir characterisation and simulation conference and exhibition, 9–11 October, Abu Dhabi, UAE. Society of Petroleum Engineers, pp 1– 21, SPE-148323-MS

Brashear J, Kuuskraa V (1978) The potential and economics of enhanced oil recovery. J Petrol Technol 30(09):1231–1239

Carcoana AN (1982) Enhanced oil recovery in Rumania. SPE enhanced oil recovery symposium, 4–7 April, Tulsa, Oklahoma. Society of Petroleum Engineers, pp 1–13. SPE-10699-MS

Caudle B, Dyes A (1958) Improving miscible displacement by gas-water injection, Society of Petroleum Engineers, SPE-911-G, pp 1–4

Diaz D, Bassiouni Z, Kimbrell W, Wolcott J (1996) Screening criteria for application of carbon dioxide miscible displacement in waterflooded reservoirs containing light oil. SPE/DOE improved oil recovery symposium, 21–24 April, Tulsa, Oklahoma. Society of Petroleum Engineers, pp 1–7, SPE-35431-MS. https://doi.org/10.2118/35431-MS

Ding M, Yuan F, Wang Y, Xia X, Chen W, Liu D (2017) Oil recovery from a CO2 injection in heterogeneous reservoirs: the influence of permeability heterogeneity, CO2-oil miscibility and injection pattern. J Nat Gas Sci Eng 44:140–149

Edwards K (2000) CO in Alberta: a vision of the future. J Can Pet Technol 39(09):1–6. https://doi.org/10.2118/00-09-04

Fulin Z (2001) The principle of EOR. Petroleum University Press, Chengdu, pp 155–164

Gao C, Li X, Guo L, Zhao F (2013) Heavy oil production by carbon dioxide injection. Greenhouse Gases Sci Technol 3(3):185–195

Geffen TM (1973) Improved oil recovery could help ease energy shortage. World Oil 177(5):84–88

Goodlett GO, Honarpour MM, Chung FT, Sarathi PS (1986) The role of screening and laboratory flow studies in EOR process evaluation. SPE rocky mountain regional meeting, 19–21 May, Billings, Montana. Society of Petroleum Engineers, pp 1–28, SPE-15172-MS. https://doi.org/10.2118/15172-MS

Goodrich JH (1980) Target reservoirs for CO2 miscible flooding: final report, vol 8341. US Department of Energy, Virginia, USA

Haynes HJ, Thrasher LW, Katz ML, Eck TR (1976) Enhanced Oil Recovery, Department of Interior. Committee on enhanced recovery techniques. Enhanced oil recovery, EOR: an analysis of the potential for enhanced oil recovery from known fields in the United States, 1976 to 2000. National Petroleum Council, USA, pp 1–200

Heidari P, Kharrat R, Alizadeh N, Ghazanfari MH (2013) A comparison of WAG and SWAG processes: laboratory and simulation studies energy sources, part a: recovery. Util Environ Effects 35:2225–2232. https://doi.org/10.1080/15567036.2010.532189

Inaloo MB, Jafari F, Helalizadeh A (2014) Comparison of water flooding, gas injection and wag injection scenarios performance in a five spot pattern. World Appl Sci J 31(1):96–103

International AR (2006) Undeveloped domestic oil resources: the foundation for increased oil production and a viable domestic oil industry. US Department of Energy, Office of Fossil Energy—Office of Oil and Natural Gas. http://www.fossil.energy.gov/programs/oilgas/publications/eor_co2/Undeveloped_Oil_Document.Pdf

Iyoho A (1978) Selecting enhanced oil recovery processes. World Oil (US) 187(6):61–64

Jaber AK, Awang MB (2017) Field-scale investigation of different miscible CO2-injection modes to improve oil recovery in a clastic highly heterogeneous reservoir. J Pet Explor Prod Technol 7(1):125–146

John PY, Zhuang Z, Kumar KH, Watts RJ (1990) A simulation approach in economic assessment and risk analysis of the CO2 miscible flooding process. J Petrol Sci Eng 4(4):359–374

Khazam M, Arebi T, Mahmoudi T, Froja M (2016) A new simple CO2 minimum miscibility pressure correlation. Oil Gas Res 2:2472-0518

Klins MA (1984) Carbon dioxide flooding: basic mechanisms and project design. Springer, Amsterdam

Kong X, Ohadi M (2010) Applications of micro and nano technologies in the oil and gas industry-overview of the recent progress. Abu Dhabi international petroleum exhibition and conference, 1–4 November, Abu Dhabi, UAE. Society of Petroleum Engineers, pp 1–11, SPE-138241-MS. https://doi.org/10.2118/138241-MS

Kovscek AR (2002) Screening criteria for CO2 storage in oil reservoirs. Pet Sci Technol 20(7–8):841–866

Kyrylovych M (2012) Applicability of hot water-alternate-CO2 flooding in heavy oil reservoirs

McRee BC (1977) CO2: how it works, where it works. Pet Eng 49(12):52–63

Monson CC, Korose CP, Frailey SM (2014) Screening methodology for regional-scale CO2 EOR and storage using economic criteria. Energy Procedia 63:7796–7808

Mousavifar MA, Kharrat R, Parchizadeh A, Mahdavi S (2012) Comparison between EOR methods (gas injection, water injection and WAG processes) in one of Iranian Fractured Oil Reservoirs

Muggeridge A, Cockin A, Webb K, Frampton H, Collins I, Moulds T, Salino P (2014) Recovery rates, enhanced oil recovery and technological limits. Philos Trans Ser A Math Phys Eng Sci 372(2006):20120320

Núñez-López V, Holtz MH, Wood DJ, Ambrose WA, Hovorka SD (2008) Quick-look assessments to identify optimal CO2 EOR storage sites. Environ Geol 54(8):1695–1706

O’Reilly D (2009) Comparative PVT simulation: an application to Australasian fluid samples. SPE annual technical conference and exhibition, 4–7 October, New Orleans, Louisiana. Society of Petroleum Engineers, pp 1–17, SPE-129517-STU. https://doi.org/10.2118/129517-STU

Orr FM, Heller JP, Taber JJ (1982) Carbon dioxide flooding for enhanced oil recovery: promise and problems. J Am Oil Chem Soc 59(10):810A–817A

OTA (Office of Technology Assessment) (1978) Enhanced oil recovery potential in United States; Congress of the United States. US Government printing Office, Washington DC, p 235

Rivas O, Embid S, Bolivar F (1994) Ranking reservoirs for carbon dioxide flooding processes. Soc Pet Eng 2(1):1–9. https://doi.org/10.2118/23641-PA

Sahimi M (2011) Miscible displacements, flow and transport in porous media and fractured rock. Wiley, New York, 467–518

Sandhu K (2012) Canadian CO2-EOR project reserves/appraisal. In: Presented at “Putting the Business Elements together for CO2 EOR using Captured Carbon” conference. 4–5 April, 2012, Golden, CO, USA

Sandrea I (2007) Global oil reserves-1: recovery factors leave vast target for EOR technologies. Oil Gas J 105(41):44

Sehbi BS, Frailey SM, Lawal AS (2001) Analysis of factors affecting microscopic displacement efficiency in CO2 floods. SPE permian basin oil and gas recovery conference, 15–17 May, Midland, Texas. Society of Petroleum Engineers, pp 1–8, SPE-70022-MS. https://doi.org/10.2118/70022-MS

Shaw J, Bachu S (2002) Screening, evaluation, and ranking of oil reservoirs suitable for CO2-flood EOR and carbon dioxide sequestration. J Can Pet Technol. https://doi.org/10.2118/02-09-05

Shedid SA (2009) Influences of different modes of reservoir heterogeneity on performance and oil recovery of carbon dioxide miscible flooding. J Can Pet Technol. https://doi.org/10.2118/09-02-29

Silva IG, de Melo MA, Luvizotto JM, Lucas EF (2007) Polymer flooding: a sustainable enhanced oil recovery in the current scenario. Latin American & caribbean petroleum engineering conference, 15–18 April, Buenos Aires, Argentina. Society of Petroleum Engineers, SPE-107727-MS. https://doi.org/10.2118/107727-MS

Song C, Yang D (2017) Experimental and numerical evaluation of CO2 huff-n-puff processes in Bakken formation. Fuel 190:145–162

Song Z, Li Z, Wei M, Lai F, Bai B (2014) Sensitivity analysis of water-alternating-CO2 flooding for enhanced oil recovery in high water cut oil reservoirs. Comput Fluids 99(Supplement C):93–103

Souza Jr , Cursino D, Padua K (2005) Twenty years of steam injection in heavy-oil fields. Proceedings of the SPE latin american and caribbean petroleum engineering conference, 20–23 June, Rio de Janeiro, Brazil, pp 20–23

Sun X, Zhang Y, Chen G, Gai Z (2017) Application of nanoparticles in enhanced oil recovery: a critical review of recent progress. Energies 10(3):345

Taber JJ (1983) Technical screening guides for the enhanced recovery of oil. SPE annual technical conference and exhibition, 5–8 October, San Francisco, California. Society of Petroleum Engineers, SPE-12069-MS. https://doi.org/10.2118/12069-MS

Taber JJ, Martin F, Seright R (1997) EOR screening criteria revisited-Part 1: Introduction to screening criteria and enhanced recovery field projects. SPE Reserv Eng 12(03):189–198

Thomas S (2008) Enhanced oil recovery-an overview. Oil Gas Sci Technol Revue de l’IFP 63(1):9–19

Todd M, Grand G (1993) Enhanced oil recovery using carbon dioxide. Energy Convers Manag 34(9):1157–1164

Whitson CH, Brulé MR (2000) Phase behavior, vol. 20. Society of Petroleum Engineers, USA, pp 1–120

Acknowledgements

We greatly acknowledge National Oil and Gas Company of Pakistan, the Oil and Gas Development Company Ltd (OGDCL) for providing research data to publish this work. Schlumberger Pakistan is also acknowledged for the Petrel tool and Eclipse Reservoir Simulator licenses.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Bhatti, A.A., Raza, A., Mahmood, S.M. et al. Assessing the application of miscible CO2 flooding in oil reservoirs: a case study from Pakistan. J Petrol Explor Prod Technol 9, 685–701 (2019). https://doi.org/10.1007/s13202-018-0504-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-018-0504-x