Abstract

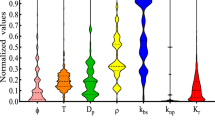

The thermal conductivity of working fluids is among the most important thermophysical property in all heat transfer equipment. Accurate estimation of the nano-fluids thermal conductivity is a prerequisite for designing and optimizing the associated heat-based equipment. Therefore, the present study simulates the thermal conduction coefficients of water–alumina nano-suspensions using the least-squares support vector machines (LS-SVM). The best structure of this paradigm is determined using a combination of trial-and-error and statistical analyses. After that, it is validated by both available empirical correlations and intelligent models available in the open literature. Our LS-SVM paradigm predicted 282 experimental data samples available in fifteen references with the absolute average relative deviation (AARD) of 1.24%, mean squared errors (MSE) of 0.0007, root mean squared errors (RMSE) of 0.026, and regression coefficient (R2) of 0.9586. The leverage technique justifies that minor parts of experimental data are outliers (~ 6.03%) and have an insignificant negative effect on the derived LS-SVM generalization. The designed simulator shows that temperature and alumina concentration positively affect the nano-fluids thermal conductivity, and alumina size reduces the thermal behavior of water–alumina nano-suspensions.

Similar content being viewed by others

References

Adib H, Sabet A, Naderifar A et al (2015) Evolving a prediction model based on machine learning approach for hydrogen sulfide removal from sour condensate of south Pars natural gas processing plant. J Nat Gas Sci Eng 27:74–81

Alade IO, Abd Rahman MA, Saleh TA (2019) Predicting the specific heat capacity of alumina/ethylene glycol nanofluids using support vector regression model optimized with Bayesian algorithm. Sol Energy 183:74–82

Amasyali K, El-Gohary NM (2018) A review of data-driven building energy consumption prediction studies. Renew Sustain Energy Rev 81:1192–1205

Ariana MA, Vaferi B, Karimi G (2015) Prediction of thermal conductivity of alumina water-based nanofluids by artificial neural networks. Powder Technol 278:1–10

Asadi A, Bakhtiyari AN, Alarifi IM (2020) Predictability evaluation of support vector regression methods for thermophysical properties, heat transfer performance, and pumping power estimation of MWCNT/ZnO–engine oil hybrid nanofluid. Eng Comput May 2020:1–11

Beck MP, Yuan Y, Warrier P, Teja AS (2009) The effect of particle size on the thermal conductivity of alumina nanofluids. J Nanoparticle Res 11:1129–1136

Beck MP, Yuan Y, Warrier P, Teja AS (2010) The thermal conductivity of alumina nanofluids in water, ethylene glycol, and ethylene glycol+ water mixtures. J Nanoparticle Res 12:1469–1477

Bellila A, Attia MEH, Kabeel AE et al (2021) Productivity enhancement of hemispherical solar still using Al2O3-water-based nanofluid and cooling the glass cover. Appl Nanosci 11:1127–1139

Buschmann MH (2012) Thermal conductivity and heat transfer of ceramic nanofluids. Int J Therm Sci 62:19–28

Chandrasekar M, Suresh S, Bose AC (2010) Experimental investigations and theoretical determination of thermal conductivity and viscosity of Al2O3/water nanofluid. Exp Therm Fluid Sci 34:210–216

Chen S, Hassanzadeh-Aghdam MK, Ansari R (2018) An analytical model for elastic modulus calculation of SiC whisker-reinforced hybrid metal matrix nanocomposite containing SiC nanoparticles. J Alloys Compd 767:632–641

Chon CH, Kihm KD, Lee SP, Choi SUS (2005) Empirical correlation finding the role of temperature and particle size for nanofluid (Al2O3) thermal conductivity enhancement. Appl Phys Lett 87:153107

Daryayehsalameh B, Nabavi M, Vaferi B (2021) Modeling of CO2 capture ability of [Bmim][BF4] ionic liquid using connectionist smart paradigms. Environ Technol Innov 22:101484

Das SK, Putra N, Thiesen P, Roetzel W (2003) Temperature dependence of thermal conductivity enhancement for nanofluids. J Heat Transf 125:567–574

Duan Z, Yin Q, Li C et al (2020) Milling force and surface morphology of 45 steel under different Al2O3 nanofluid concentrations. Int J Adv Manuf Technol 107:1277–1296

Edgar TF, Himmelblau DM, Lasdon LS (2002) Optimization of chemical processes. McGraw-Hill, New York

Gao T, Li C, Zhang Y et al (2019) Dispersing mechanism and tribological performance of vegetable oil-based CNT nanofluids with different surfactants. Tribol Int 131:51–63

Gao T, Li C, Jia D et al (2020) Surface morphology assessment of CFRP transverse grinding using CNT nanofluid minimum quantity lubrication. J Clean Prod 277:123328

Gholami E, Vaferi B, Ariana MA (2018) Prediction of viscosity of several alumina-based nanofluids using various artificial intelligence paradigms—comparison with experimental data and empirical correlations. Powder Technol 323:495–506

Hajabdollahi H, Dehaj MS (2021) Experimental study and optimization of friction factor and heat transfer in the fin and tube heat exchanger using nanofluid. Appl Nanosci 11:657–668

Hassanpour M, Vaferi B, Masoumi ME (2018) Estimation of pool boiling heat transfer coefficient of alumina water-based nanofluids by various artificial intelligence (AI) approaches. Appl Therm Eng 128:1208–1222

Jahanmahin O, Kirby DJ, Smith BD et al (2020) Assembly of gold nanowires on gold nanostripe arrays: simulation and experiment. J Phys Chem C 124:9559–9571

Jiang Y, Zhang G, Wang J, Vaferi B (2021) Hydrogen solubility in aromatic/cyclic compounds: prediction by different machine learning techniques. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2021.04.148

Kaabipour S, Hemmati S (2021) A review on the green and sustainable synthesis of silver nanoparticles and one-dimensional silver nanostructures. Beilstein J Nanotechnol 12:102–136

Keshtkar Z, Tamjidi S, Vaferi B (2021) Intensifying nickel (II) uptake from wastewater using the synthesized γ-alumina: an experimental investigation of the effect of nano-adsorbent properties and operating conditions. Environ Technol Innov 22:101439

Khalifeh A, Vaferi B (2019) Intelligent assessment of effect of aggregation on thermal conductivity of nanofluids—comparison by experimental data and empirical correlations. Thermochim Acta 681:178377

Li CH, Peterson GP (2006) Experimental investigation of temperature and volume fraction variations on the effective thermal conductivity of nanoparticle suspensions (nanofluids). J Appl Phys 99:84314

Li CH, Peterson GP (2007) The effect of particle size on the effective thermal conductivity of Al2O3-water nanofluids. J Appl Phys 101:44312

Liu W, Zhou Y, Shi P (2020) Electrokinetic ion transport at micro–nanochannel interfaces: applications for desalination and micromixing. Appl Nanosci 10:751–766

Longo GA, Zilio C (2011) Experimental measurement of thermophysical properties of oxide–water nano-fluids down to ice-point. Exp Therm Fluid Sci 35:1313–1324

Manimaran R, Palaniradja K, Alagumurthi N et al (2014) Preparation and characterization of copper oxide nanofluid for heat transfer applications. Appl Nanosci 4:163–167

Mintsa HA, Roy G, Nguyen CT, Doucet D (2009) New temperature dependent thermal conductivity data for water-based nanofluids. Int J Therm Sci 48:363–371

Moosavi SR, Vaferi B, Wood DA (2021) Auto-characterization of naturally fractured reservoirs drilled by horizontal well using multi-output least squares support vector regression. Arab J Geosci 14:545

Murshed SMS, Leong KC, Yang C (2008) Investigations of thermal conductivity and viscosity of nanofluids. Int J Therm Sci 47:560–568

Nan C-W, Birringer R, Clarke DR, Gleiter H (1997) Effective thermal conductivity of particulate composites with interfacial thermal resistance. J Appl Phys 81:6692–6699

Ramezanizadeh M, Ahmadi MH, Nazari MA et al (2019) A review on the utilized machine learning approaches for modeling the dynamic viscosity of nanofluids. Renew Sustain Energy Rev 114:109345

Sahaluddin M, Alade IO, Oyedeji MO, Aliyu US (2020) A machine learning-based model to estimate the density of nanofluids of nitrides in ethylene glycol. J Appl Phys 127:205105

Saranprabhu MK, Rajan KS (2019) Enhancement of solid-phase thermal conductivity and specific heat of solar salt through addition of MWCNT: new observations and implications for thermal energy storage. Appl Nanosci 9:2117–2126

Seaberg J, Kaabipour S, Hemmati S, Ramsey JD (2020) A rapid millifluidic synthesis of tunable polymer-protein nanoparticles. Eur J Pharm Biopharm 154:127–135

Shadloo MS (2020) Application of support vector machines for accurate prediction of convection heat transfer coefficient of nanofluids through circular pipes. Int J Numer Methods Heat Fluid Flow. https://doi.org/10.1108/HFF-09-2020-0555

Srivastava S (2012) Effect of aggregation on thermal conductivity and viscosity of nanofluids. Appl Nanosci 2:325–331

Sui M, Li C, Wu W et al (2021) Temperature of grinding carbide with castor oil-based MoS2 nanofluid minimum quantity lubrication. J Therm Sci Eng Appl 13:51001

Suykens JAK, Van Gestel T, De Brabanter J et al (2002) Least squares support vector machines. World Scientific Publishing, Singapore

Teng T-P, Hung Y-H, Teng T-C et al (2010) The effect of alumina/water nanofluid particle size on thermal conductivity. Appl Therm Eng 30:2213–2218

Timofeeva EV, Gavrilov AN, McCloskey JM et al (2007) Thermal conductivity and particle agglomeration in alumina nanofluids: Experiment and theory. Phys Rev E Stat Nonlinear Soft Matter Phys 76:28–39

Vaferi B, Eslamloueyan R (2015) Hydrocarbon reservoirs characterization by co-interpretation of pressure and flow rate data of the multi-rate well testing. J Pet Sci Eng 135:59–72

Vaferi B, Samimi F, Pakgohar E, Mowla D (2014) Artificial neural network approach for prediction of thermal behavior of nanofluids flowing through circular tubes. Powder Technol 267:1–10

Waheed R, Sarwar S, Wei C (2019) The survey of economic growth, energy consumption and carbon emission. Energy Rep 5:1103–1115

Wang B, Zhang Z, Chang K et al (2018) New deformation-induced nanostructure in silicon. Nano Lett 18:4611–4617

Wang X, Li C, Zhang Y et al (2020) Vegetable oil-based nanofluid minimum quantity lubrication turning: academic review and perspectives. J Manuf Process 59:76–97

Xie H, Fujii M, Zhang X (2005) Effect of interfacial nanolayer on the effective thermal conductivity of nanoparticle-fluid mixture. Int J Heat Mass Transf 48:2926–2932

Xie W, Zhang Z, Liao L et al (2020) Green chemical mechanical polishing of sapphire wafers using a novel slurry. Nanoscale 12:22518–22526

Xu X, Karami B, Shahsavari D (2021) Time-dependent behavior of porous curved nanobeam. Int J Eng Sci 160:103455

Yang Y, Chen H, Zou X et al (2020) Flexible carbon-fiber/semimetal Bi nanosheet arrays as separable and recyclable plasmonic photocatalysts and photoelectrocatalysts. ACS Appl Mater Interfaces 12:24845–24854

Yang M, Li C, Luo L et al (2021) Predictive model of convective heat transfer coefficient in bone micro-grinding using nanofluid aerosol cooling. Int Commun Heat Mass Transf 125:105317

Yiamsawasd T, Dalkilic AS, Wongwises S (2012) Measurement of the thermal conductivity of titania and alumina nanofluids. Thermochim Acta 545:48–56

Yu W, Choi SUS (2003) The role of interfacial layers in the enhanced thermal conductivity of nanofluids: a renovated Maxwell model. J Nanoparticle Res 5:167–171

Zhang X, Zhang Y (2021a) Experimental study on enhanced heat transfer and flow performance of magnetic nanofluids under alternating magnetic field. Int J Therm Sci 164:106897

Zhang X, Zhang Y (2021b) Heat transfer and flow characteristics of Fe3O4-water nanofluids under magnetic excitation. Int J Therm Sci 163:106826

Zhang X, Gu H, Fujii M (2007) Effective thermal conductivity and thermal diffusivity of nanofluids containing spherical and cylindrical nanoparticles. Exp Therm Fluid Sci 31:593–599

Zhang Z, Huo F, Zhang X, Guo D (2012a) Fabrication and size prediction of crystalline nanoparticles of silicon induced by nanogrinding with ultrafine diamond grits. Scr Mater 67:657–660

Zhang Z, Song Y, Xu C, Guo D (2012b) A novel model for undeformed nanometer chips of soft-brittle HgCdTe films induced by ultrafine diamond grits. Scr Mater 67:197–200

Zhang Z, Huo Y, Guo D (2013) A model for nanogrinding based on direct evidence of ground chips of silicon wafers. Sci China Technol Sci 56:2099–2108

Zhang Y, Li C, Jia D et al (2015a) Experimental evaluation of the lubrication performance of MoS2/CNT nanofluid for minimal quantity lubrication in Ni-based alloy grinding. Int J Mach Tools Manuf 99:19–33

Zhang Z, Wang B, Kang R et al (2015b) Changes in surface layer of silicon wafers from diamond scratching. Cirp Ann 64:349–352

Zhang Z, Cui J, Wang B et al (2017a) A novel approach of mechanical chemical grinding. J Alloys Compd 726:514–524

Zhang Z, Huang S, Wang S et al (2017b) A novel approach of high-performance grinding using developed diamond wheels. Int J Adv Manuf Technol 91:3315–3326

Zhang Z, Shi Z, Du Y et al (2018) A novel approach of chemical mechanical polishing for a titanium alloy using an environment-friendly slurry. Appl Surf Sci 427:409–415

Zhang Z, Cui J, Zhang J et al (2019) Environment friendly chemical mechanical polishing of copper. Appl Surf Sci 467:5–11

Zhang J, Wu W, Li C, et al (2020a) Convective heat transfer coefficient model under nanofluid minimum quantity lubrication coupled with cryogenic air grinding Ti–6Al–4V. Int J Precis Eng Manuf Technol 8:1113–1135

Zhang Z, Liao L, Wang X et al (2020b) Development of a novel chemical mechanical polishing slurry and its polishing mechanisms on a nickel alloy. Appl Surf Sci 506:144670

Zhang Z, Liu J, Hu W et al (2021) Chemical mechanical polishing for sapphire wafers using a developed slurry. J Manuf Process 62:762–771

Zhu H, An Y, Shi M et al (2021) Porous N-doped carbon/MnO2 nanoneedles for high performance ionic liquid-based supercapacitors. Mater Lett 296:129837

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

For this type of study formal consent is not required.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nabavi, M., Nazarpour, V., Alibak, A.H. et al. Smart tracking of the influence of alumina nanoparticles on the thermal coefficient of nanosuspensions: application of LS-SVM methodology. Appl Nanosci 11, 2113–2128 (2021). https://doi.org/10.1007/s13204-021-01949-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-021-01949-7