Abstract

Polygalacturonases represents an important member of pectinases group of enzymes with diverse industrial applications and is widely distributed among fungi, bacteria, yeasts, plants and some plant parasitic nematodes. An endo-polygalacturonase from a new fungal source Aspergillus fumigatus MTCC 2584 was produced under solid-state fermentation conditions and was purified simply by acetone precipitation and gel-filtration chromatography technique. The approximate molecular weight of the purified PG was found to be 43.0 kDa as revealed by SDS-PAGE. The pH optimum of the purified enzyme was found to be 10.0 and was stable in the pH range of 7–10. The optimum temperature of purified PG was found to be 30 °C. The Km and Kcat of the purified enzyme were 2.4 mg/ml and 44 s−1, respectively, and the metal ions Cu2+ and K+ were found to enhance the enzyme activity while Ag+, Ca2+ and Hg2+ were inhibitory in nature. Based on its alkaline nature, the potential of purified PG in retting of natural fiber Crotalaria juncea was elucidated in the absence of EDTA. This is probably the first report of alkaline PG from Aspergillus fumigatus.

Similar content being viewed by others

Introduction

Polygalacturonases (PGs) (EC 3.2.1.15) are important member of pectinases which catalyze the hydrolysis of α-1,4-D-galacturonic acid linkages in smooth region of pectin. Depending on their mode of hydrolysis of the substrate, PGs are classified as endo-PGs (E.C. 3.2.1.15) and exo-PGs (EC 3.2.1.67). The endo-PGs cleave the α-1,4-D-galacturonic acid linkages randomly, whereas exo-PGs cleave the linkage from non-reducing end (Anand et al. 2014). Endo-PGs are generally found in extracellular environment and exo-PGs in the periplasm. This localization is in coherence with the substrate accumulation in each environment, endo-PG would degrade extracellular polymerized forms of pectin present within the plant cell wall and exo-PGs would produce small oligogalacturonides and monogalacturonic acid from pectic fragments that accumulate in periplasm for intracellular transport (Abbott and Boraston 2008).

Polygalacturonases are widely distributed among fungi, bacteria, yeasts, plants and some plant parasitic nematodes (Niture 2008). The genera Aspergillus is an important source of PGs. Several endo-PGs and exo-PGs have been purified and characterized from different species of Aspergillus like Aspergillus niger (Parenicova et al. 1998; Zhou et al. 2015), A. awamori (Nagai et al. 2000), A. carbonarius (Nakkeeran et al. 2011), A. tubingensis (Kester et al. 1996), A. niger (Sakamoto et al. 2002), A. sojae (Dogan and Tari 2008) and Aspergillus sojae (Buyukkileci et al. 2014).

PGs being of great industrial importance, knowledge of their biochemical properties is essential for their utilization in relevant industries. The pH optima of purified PGs determines its possible application like fruit juice clarification, retting of natural fibers etc. It has been observed that most of the fungal PGs have pH optima 3–6 (Patil et al. 2012; Yadav et al. 2012; Kant et al. 2013; Martins et al. 2013; Castruita-Domínguez et al. 2014; Ortega et al. 2014; Chen et al. 2014; Zhou et al. 2015; Zaslona and Trusek-Holownia 2015; Pan et al. 2015).

Most of the fungal PGs show temperature optima between 35 and 60 °C, though few thermophilic fungal strains like Aspergillus sojae, Paecilomyces variotii, Thermoascus aurantiacus with temperature optima in the range of 60–70 °C have been reported (Dogan and Tari 2008; de Lima Damasio et al. 2010; Martins et al. 2007, 2013).

Alkaline polygalacturonases have been reported from bacterial strains, Bacillus in particular (Kobayashi et al. 2001), and alkaline PG having application in retting of natural fibers is a rare finding. Keeping the above points in view, authors have reported purification and characterization of an alkaline PG from fungal strain Aspergillus fumigatus MTCC 2584 under solid-state fermentation conditions and elucidated its application in retting of Crotalaria juncea fibers. Thus, it could be a potential enzyme for textile or paper industries.

Materials and methods

Chemicals

Polygalacturonic acid (PGA) and Sephadex G-100 were purchased from Sigma Chemical Company (St. Louis, MO, USA). Rests of the chemicals were procured either from Merck (Navi Mumbai, India) or S.D. Fine (Mumbai, India) and were used without further purification.

Microorganism and culture condition

The fungal strain Aspergillus fumigatus MTCC 2584 was procured from Microbial Type Culture Collection and Gene Bank, Institute of Microbial Technology, Chandigarh (India) and screened for pectinase production by plate assay method (Molina et al. 2001). The culture was maintained by cultivation on Czapek-Dox agar slants at 26 °C.

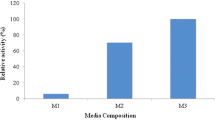

Solid-state fermentation

The enzyme was produced by solid-state fermentation. The production medium consisted of wheat bran 4.5 g, tea extract 0.5 g and 5 ml salt solution. The composition of salt solution was (4 g/L each of K2HPO4, KH2PO4, and NH4SO4). The organism was grown on Czapek-Dox agar slants. The inoculum was prepared by suspending the spores of the slants in sterile distilled water and counted using a hemocytometer. Ten 250 ml Erlenmeyer flasks containing solid medium were inoculated with 1 ml spore suspension (5 × 106 spores/ml) in each flask; the flasks were kept at 26 °C in a biological oxygen demand (BOD) incubator. Maximum production of the enzyme occurred on 5th day of inoculation.

Enzyme extraction

On fifth day, 15 ml chilled distilled water was added to each flask and the resulting mixture was homogenized by a glass rod. The homogenate was extracted through four layers of cheese cloth and the filtrate was centrifuged at 14,000 g for 20 min and clear supernatant was obtained that was used as a crude enzyme for further purification.

PG assay

Enzyme activity of PG was assayed by determining the liberated reducing end products by standard method (Miller 1959). The reaction solution (2 mL) consisted of 0.5 mL of 1 % PGA, 1.4 mL 100 mM glycine-NaOH buffer (pH 10.0) and 0.1 mL enzyme solution. It was incubated for 20 min at 37 °C in a water bath. Three mL of dinitrosalicyclic acid (DNSA) reagent was added and volume was made 6 mL by addition of 1 mL distilled water. The solution was boiled for 10 min in a water bath, cooled and absorbance was read at 575 nm in a colorimeter. A control was simultaneously prepared taking thermally denatured enzyme. The concentration of the product (galacturonic acid) was determined with the help of a calibration curve. One unit of PG activity is defined as the amount of enzyme that liberates 1 μmol of galacturonic acid per min under the assay conditions. All experiments were performed in triplicates and were found to have standard deviation of less than 5 %.

Enzyme purification

Chilled acetone was added slowly up to 60 % saturation with gentle stirring at 4 °C to the crude enzyme extract. The treated crude enzyme solution was allowed to stand overnight in the refrigerator, and centrifuged at 10,000 rpm for 15 min. The supernatant was discarded and pellet was dissolved in 3 mL of cold distilled water. The concentrated enzyme after acetone precipitation was loaded on a Sephadex G-100 column (1.0 × 30.0 cm), pre-equilibrated with 100 mM citrate phosphate buffer (pH 7.0). The flow rate was maintained at 12.0 ml/h and fractions were collected and analyzed for protein and polygalacturonase activity. The active fractions were pooled, assayed and stored in deep fridge at −20 °C. The purity of the enzyme was checked by sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS–PAGE) in 10 % acrylamide gel according to Laemmli (1970).

Biochemical characterization of purified polygalacturonase

The pH optimum was determined by measuring steady-state velocity using 0.5 g % PGA in the buffered reaction solution using different buffers at 100 mM in the pH range 1.0–12.0. The different buffers used were: hydrochloric acid–potassium chloride (pH 1.0–2.0), citrate–phosphate (pH 3.0–7.0), sodium phosphate (pH 8.0), glycine–sodium hydroxide (pH 9.0–10.0) and sodium phosphate–sodium hydroxide (pH 11.0–12.0). The pH stability of the enzyme was studied by exposing the enzyme to buffers of different pH for 24 h at 4 °C. The activities were assayed by the method described in enzyme assay section and plotted in the form of relative activity versus pH.

The optimum temperature for the enzyme activity was determined by assaying the activity of the enzyme at different temperatures in the range 10–100 °C and plotting a graph of the enzyme activity versus temperature of the reaction solutions. Thermal stability of the enzyme was tested by incubating enzyme aliquots at a particular temperature (10–100 °C) for 2 h and their activities were assayed using the standard assay method.

The Km and Kcat values of the purified enzyme were determined by measuring steady-state velocities of the enzyme-catalyzed reaction at different concentrations of citrus PGA (0.05–0.6 g % w/w) in 100 mM glycine–NaOH buffer (pH 10.0) at 30 °C and drawing double reciprocal plot (Engel 1977). Calculations were made using linear regression analysis of the data points of the double reciprocal plot.

Effect of metal ions and protein inhibitors

The effects of metal ions, such as Ca2+, Mn2+, Co2+, Cu2+, Zn2+, Hg2+, K+, Na+, Ag+ and protein inhibitors like potassium permanganate, potassium ferrocyanide and ethylenediaminetetraacetic acid (EDTA), were studied by measuring the steady-state velocity in the reaction solutions containing 1 mM of the metal ions or protein inhibitors and comparing it with the value in the absence of these ions or inhibitors.

Mode of action of purified polygalacturonase

To decide whether the purified PG is an exo- or endo-PG, a reaction solution containing 0.5 mL of 1 % PGA in distilled water and 1.4 mL of 100 mM glycine–NaOH buffer (pH 10.0) was added in a test tube. The test tube was incubated in a water bath at 30 °C and was allowed to stand to maintain the temperature for 20 min; 0.5 unit of the purified enzyme was added. 3 μL aliquots of the reaction solution were withdrawn at 15, 30 and 45 min and spots of these solutions were made on thin layer chromatography (TLC) plate coated with silica gel. Spots of monogalacturonic acid as well as PGA were also made. The TLC plate was kept in a jar containing a solution of butanol, water and acetic acid in the volume ratio 5:3:2 as mobile phase. The TLC plates were air dried, and sprayed with 0.2 % (w/v) orcinol in methanol and 10 % sulfuric acid. The plate was air dried and kept in an oven at 80 °C for 10 min. The spots were photographed.

Retting of Crotalaria juncea fiber by purified PG

The retting of Crotalaria juncea natural fiber was carried out by the reported method (Zhang et al. 2005) with minor modifications. Approximately, 5.0 cm long sticks were kept in three test tubes. In each test tube, 10 mL of 100 mM glycine–NaOH buffer (pH 10.0) was added. One test tube was made control designated as ‘A’ and contained deactivated enzyme. The other test tubes were designated as ‘B’ containing purified enzyme with EDTA and ‘C’ containing purified enzyme without EDTA. All the test tubes were incubated in a water bath at 37 °C for 24 h. After 24 h, the sticks were shaken vigorously each with 10 mL hot water for 1 min, hot water was poured off and the resulting sticks were photographed.

Results and discussion

Purification of polygalacturonase

The purification of PG produced by Aspergillus fumigatus MTCC 2584 was performed by acetone precipitation and gel-filtration column chromatography. The purification chart is shown in Table 1.

The crude enzyme harvested on fifth day of fermentation and the clear culture filtrate was centrifuged and subjected to acetone precipitation (0–60 % saturation). The precipitate obtained after the acetone precipitation revealed 3.13-fold purification with 4.33 % yield and 6.61 U/mg specific activity (Table 1). The concentrated enzyme after acetone precipitation was loaded on a Sephadex G-100 column (1.0 × 30.0 cm), pre-equilibrated with 100 mM citrate phosphate buffer (pH 7.0). The flow rate was maintained at 12.0 ml/h and fractions were collected and analyzed for protein and PG activity. The gel-filtration chromatography resulted in an 18.43-fold purification with specific activity of 38.9 U/mg protein and 2.98 % yield (Table 1).

The purified polygalacturonase was confirmed for electrophoretic homogeneity by SDS-PAGE. The single band corresponding to a relative molecular mass of approximately 43.0 kDa was observed (Fig. 1). An endo-PG of 41.0 kDa has been reported from Aspergillus awamori (Nagai et al. 2000).

Effect of pH on the activity and stability of PG

The optimum pH for the purified polygalacturonase was found to be 10.0 and the enzyme was stable for a pH range, i.e., 7.0–11.0 (Fig. 2a, b) when exposed to buffers of various pH for 24 h, indicating its suitability for retting of natural fibers. Even at a high pH of 12.0, more than 70 % of the activity was retained. An alkaline PG with pH optima 10.0 has been reported from Bacillus sp. (Kapoor et al. 2000). The author could not find report of alkaline PG from fungal sources for comparison.

Effect of temperature on the activity and stability of PG

Optimum temperature for the purified polygalacturonase activity was found to be 30 °C and the enzyme retained its maximum activity between 10 and 30 °C for 2 h (Fig. 2c, d). Approximately, 54 % of the activity was found at 40 °C which declined to 38.4 % at 50 °C (Fig. 2d). Optimum temperature of 34 °C has been reported for endo-PG from pathogenic fungus Ustilago maydis (Castruita-Domínguez et al. 2014). Similar temperature optimum of 30 °C has been reported for exo-PG from Paecilomyces variotii (Patil et al. 2012).

Kinetic parameters

The apparent Km value for degradation of PGA by the purified enzyme was found to be 2.4 mg/mL (data not shown). Endo-PGs from Penicillium frequentans and Saccharomyces cerevisiae have Km values 2.7 and 4.2 mg/ml respectively (De Fatima Borin et al. 1996; Blanco et al. 1994 ). The catalytic rate constant (k cat ) of purified PG was found to be 44 s−1. The k cat values of 90 and 70 s−1 for endo-PGs from Aspergillus japonicus and Fusarium moniliforme have been reported (Semenova et al. 2002; Niture et al. 2001). Exo-PG from alkaliphilic Bacillus has k cat value 22.2 s−1 (Kapoor et al. 2000).

Effect of metal ions and protein inhibitors

The effect of different metal ions and protein inhibitors on the activity of the purified PG was attempted. The concentration of metal ions was kept 1 mM concentration in the reaction solution (Table 2). The metal ions namely Cu2+ and K+ were found to enhance the PG activity, while Ag+, Ca2+ and Hg2+ inhibited the enzyme activity. Metal ions, namely Mn2+, Na+, Zn2+ and protein inhibitor KMnO4 had no effect on PG activity.

Mode of action of purified PG

The mode of action of purified PG was determined by TLC method as shown in Fig. 3. The reaction spots appeared between monogalacturonic acid and polygalacturonic acid spot, revealing the endo-type of reaction mechanism producing oligogalacturonates by random cleavage as manifested by spots visible between the monomer and the polymeric substrate. Endo-PGs of molecular weight 40.0 and 39.7 kDa have been reported from F. graminearum and Phytophthora parasitica, respectively (Ortega et al. 2014; Yan and Liou 2005).

Application of purified PG in retting of Crotalaria juncea fibers

Microbial enzymes are extensively applied for retting of fibers including the pectinases (Yadav et al. 2016). The purified PG showed retting of locally available Crotalaria juncea natural fiber in the absence of EDTA (Fig. 4c). In general, acidic pectins and Ca2+ are located preferentially in the epidermal regions of Linum usitatissimum (flax) (Rihouey et al. 1995), contributing to the structural integrity of the stem and bast fibers. Therefore, chelators, such as EDTA, have the ability to remove Ca2+ and thus enhancing retting of flax (Henriksson et al. 1997, 1999). The variability in the pectin content along with Ca2+ in different fibers might influence the retting efficiency in the presence or absence of EDTA. Since EDTA was found to be slightly inhibitory to polygalacturonase activity, hence lower retting efficiency was observed in the presence of EDTA. The role of alkaline and thermostable polygalacturonase from Bacillus sp. MG-cp-2 in degumming of ramie (Boehmeria nivea) and sunn hemp (Crotolaria juncia) bast fiber has been reported (Kapoor et al. 2001). It has also been reported that a purified (endo) PGase from Aspergillus niger was capable of retting flax (Zhang et al. 2000).

Conclusions

An endo-PG from Aspergillus fumigatus MTCC 2584 produced by solid-state fermentation was purified by acetone precipitation and gel-filtration chromatography resulting in 18.43-fold purification with specific activity of 38.9 IU/mg protein and 2.98 % yield. The purified PG has a relative molecular mass of approximately 43.0 kDa as revealed by SDS–PAGE and was alkaline in nature with pH optima of 10.0. The enzyme was found to be efficient in retting of natural fiber Crotalaria juncea in the absence of EDTA. To the best of our information, this is probably the first report of PG from Aspergillus fumigatus.

References

Abbott DW, Boraston AB (2008) Structural biology of pectin degradation by Enterobacteriaceae. Microbiol Mol Biol Rev 72(2):301

Anand G, Yadav S, Dubey A K, Yadav D (2014) Molecular biology of microbial polygalacturonases: A review. In Recent developments in Biotechnology (Guest Editor: Rupinder Tewari; Executive Editor: J.N Govil), Studium Press, USA, pp 1–29 (ISBN:1-62699-018-2)

Blanco P, Sieiro C, D|èaz A, Villa TG (1994) Production and partial characterization of an endopolygalacturonase from Saccharomyces cerevisiae. Can J Microbiol 40:974–977

Buyukkileci AO, Lahore MF, Tari C (2014) Utilization of orange peel, a food industrial waste, in the production of exo-polygalacturonase by pellet forming Aspergillus sojae. Bioprocess Biosyst Eng 38(4):749–760

Castruita-Domínguez JP, González-Hernández SE, Polaina J, Flores-Villavicencio LL, Alvarez-Vargas A, Flores-Martínez A, Ponce-Noyola P, Leal-Morales CA (2014) Analysis of a polygalacturonase gene of Ustilago maydis and characterization of the encoded enzyme. J Basic Microbiol 54(5):340–349

Chen Y, Sun D, Zhou Y, Liu L, Han W, Zeng B, Wang Z, Zang Z (2014) Cloning, expression and characterization of a novel thermophilic polygalacturonase from Caldicellulosiruptor bescii DSM 6725. Int J Mol Sci 15(4):5717–5729

De Fatima Borin M, Sais S, Fonseca MJV (1996) Purification and biochemical characterization of an extracellular endopolygalacturonase from Penicillium frequentans. J Agric Food Chem 44:1616–1620

de Lima Damasio AR, Da Silva TM, Maller A, Jorqe JA, Terenzi HF, Polizeli Mde L (2010) Purification and partial characterization of an exo-polygalacturonase from Paecilomyces variotii liquid cultures. Appl Biochem Biotechnol 160(5):1496–1507

Dogan N, Tari C (2008) Characterization of three phase partitioned exo-polygalacturonase from Aspergillus sojae with unique properties. Biochem Eng J 39(1):43–50

Engel PC (1977) Enzyme kinetics a steady state approach. Chapman and Hall, New York

Henriksson G, Akin DE, Rigsby LL, Patel N, Eriksson KEL (1997) Influence of chelating agents and mechanical pretreatment on enzymatic retting of flax. Text Res J 67:829–836

Henriksson G, Akin DE, Slomczynski D, Eriksson KEL (1999) Production of highly efficient enzymes for flax retting by Rhizomucor pusillus. J Biotechnol 68:115–123

Kant S, Vohra A, Gupta R (2013) Purification and physicochemical properties of polygalacturonase from Aspergillus niger MTCC 3323. Prot Expr Purif 87(1):11–16

Kapoor M, Beg QK, Bhushan B, Dadhich KS, Hoondal GS (2000) Production and partial purification and characterization of a thermo-alkalistable polygalacturonase from Bacillus sp. MG-cp-2. Process Biochem 36:467–473

Kapoor M, Beg QK, Bhushan B, Singh K, Dadhich KS, Hoondal GS (2001) Application of an alkaline thermostable polygalacturonase from Bacillus sp. MG-cp-2 in degumming of ramie (Boehmeria nivea) and sunn hemp (Crotalaria juncea) bast fibers. Process Biochem 36:803–807

Kester HCM, Kusters-Van Someren MA, Muller Y, Visser J (1996) Primary structure and characterization of an exopolygalacturonase from Aspergillus tubingensis. Eur J Biochem 240:238–246

Kobayashi T, Higaki N, Suzumatsu A, Sawada K, Haqihara H et al (2001) Purification and properties of a high-molecular-weight, alkaline exo-polygalacturonase from a strain of Bacillus. Enzym Microb Technol 29:70–75

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685

Martins ES, Silva D, Leite RSR, Gomes E (2007) Production and characterization of polygalacturonase produced by thermophilic Thermoascus aurantiacus CBMAI-756 in submerged fermentation. A Van Leeuw 91:291–299

Martins ES, Leite RSR, Silva R, Gomes E (2013) Purification and properties of polygalacturonase produced by thermophilic fungus Thermoascus aurantiacus CBMAI-756 on solid-state fermentation. Enzym Res. doi:10.1155/2013/438645

Miller GL (1959) Use of dinitrosalicylic acid for reagent for determination of reducing sugar. Anal Chem 31:426–428

Molina SMG, Pelissari FA, Vitorello CBM (2001) Screening and genetic improvement of pectinolytic fungi for degumming of textile fibres. Braz J Microbiol 32:320–326

Nagai M, Katsuragi T, Terashita T, Yoshikawa K, Sakai T (2000) Purification and characterization of an endo-polygalacturonase from Aspergillus awamori. Biosci Biotechnol Biochem 64(8):1729–1732

Nakkeeran E, Umesh-Kumar S, Subramanian R (2011) Aspergillus carbonarius polygalacturonases purified by integrated membrane process and affinity precipitation for apple juice production. Bioresour Technol 102:3293–3297

Niture SK (2008) Comparative biochemical and structural characterizations of fungal polygalacturonases. Biologia 63(1):1–19

Niture SK, Pant A, Kumar AR (2001) Active site characterization of the single endo-polygalacturonase produced by Fusarium moniliforme NCIM 1276. Eur J Biochem 268:832–840

Ortega LM, Kikot GE, Rojas NL, Lopez LM, Astoreca AL et al (2014) Production, characterization, and identification using proteomic tools of a polygalacturonase from Fusarium graminearum. J Basic Microbiol 54:S170–S177

Pan X, Li K, Ma R, Shi P, Huang H et al (2015) Biochemical characterization of three distinct polygalacturonases from Neosartorya fischeri P1. Food Chem 188:569–575

Parenicova L, Benen JA, Kester HC, Visser J (1998) pgaE encodes a fourth member of the endopolygalacturonase gene family from Aspergillus niger. Eur J Biochem 251:72–80

Patil NP, Patil KP, Chaudhari BL, Chincholkar SB (2012) Production, purification of exo-polygalacturonase from soil isolates Paecilomyces variotii NFCCI 1739 and its application. Indian J Microbiol 52(2):240–246

Rihouey C, Jauneau A, Cabin-Flaman A, Demarty M, Lefevre F et al (1995) Calcium and acidic pectin distribution in flax cell walls: Evidence for different kinds of linkages in the cell junction and middle lamella of the cortical parenchyma of flax hypocotyl. Plant Physiol Biochem 33:497–508

Sakamoto T, Bonnin E, Quemener B, Thibault JF (2002) Purification and characterization of two exo-polygalacturonases from Aspergillus niger able to degrade xylogalacturonan and acetylated homogalacturonan. Biochim Biophys Acta 1572(1):10–18

Semenova MV, Grishutin SG, Gusakov AV, Okunev ON, Sinitsin AP (2002) Isolation and properties of Pectinases from the fungus Aspergillus japonicus. Biochemistry (Moscow) 68(5):559–569

Yadav S, Anand G, Dubey AK, Yadav D (2012) Purification and characterization of an exo-polygalacturonase secreted by Rhizopus oryzae MTCC1987 and its role in retting of Crotalaria juncea fibre. Biologia 67(6):1069–1074

Yadav D, Yadav S, Dwivedi R, Anand G, Yadav PK (2016) Potential of Microbial Enzymes in Retting of Natural Fibers: A Review. Curr Biochem Eng 3(2):89–99

Yan H, Liou R (2005) Cloning and analysis of pppg1, an inducible endopolygalacturonase gene from oomycete plant pathogen phytophthora parasitica. Fungal Genet Biol 42:339–350

Zaslona H, Trusek- Holownia A (2015) Enhanced production of polygalacturonase in solid-state fermentation: selection of the process conditions, isolation and partial characterization of the enzyme. Acta Biochim Pol 62(4):651–657

Zhang J, Henriksson G, Johansson G (2000) Polygalacturonase is the key component in enzymatic retting of flax. J Biotechnol 81:85–89

Zhang J, Henriksson H, Szabo IJ, Henriksson G, Johansson G (2005) The active component in the flax-retting system of the zygomycete Rhizopus oryzae sb is a family 28 polygalacturonase. J Ind Microbiol Biotechnol 32:431–438

Zhou H, Li X, Guo M, Xu Q, Cao Y, Qiao D et al (2015) Secretory Expression and Characterization of an Acidic Endo-Polygalacturonase from Aspergillus niger SC323 in Saccharomyces cerevisiae. J Microbiol Biotechnol 25(7):999–1006

Acknowledgments

GA would like to acknowledge Jawaharlal Nehru Memorial Fund for providing Jawaharlal Nehru Memorial Scholarship for doctoral studies. The financial support by Department of Science and Technology, Government of India, New Delhi, in the form of SERB Young Scientist Fellowship (SB/FT/LS-430/2012) to S. Yadav is also thankfully acknowledged. The authors acknowledge the infrastructural support from the Head, Department of Biotechnology, D.D.U. Gorakhpur University, Gorakhpur.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Anand, G., Yadav, S. & Yadav, D. Purification and characterization of polygalacturonase from Aspergillus fumigatus MTCC 2584 and elucidating its application in retting of Crotalaria juncea fiber. 3 Biotech 6, 201 (2016). https://doi.org/10.1007/s13205-016-0517-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-016-0517-4