Abstract

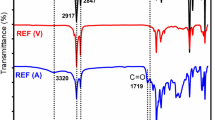

In this study, the effects of high vinyl solution styrene-butadiene rubber (SSBR) containing different macrostructures and chain-end functional groups were investigated with respect to the dispersion of silica in the compounds. The microstructures and functional groups of three polymers were analyzed by using 1H nuclear magnetic resonance (NMR). According to the 1H NMR analysis, the star-shaped SSBR-E has a relatively higher numbers of ethoxy group in the polymer chain. All compounds showed good silica dispersion based on transmission electron microscopy (TEM) observation. According to analysis of the Payne effect, longer mixing times showed better dispersion of silica in the rubber compounds, and functional group differences in the SSBR also had an effect on the degree of silica dispersion that led to a decrease in storage modulus. In particular, the compound with star-shaped polymer containing ethoxy silyl groups showed the lowest storage modulus due to a higher number of functional groups compared to the other polymers. The abrasion resistance was closely related to the silica dispersion as well as the filler-rubber interaction. The abrasion loss decreased slightly when the mixing time was extended; however, this significantly decreased when the number of functional groups in the polymer chain was increased. Accordingly, the star-shaped polymer containing higher numbers of the functional group contributed to a better dispersion of silica in the compound. Mixing time was also considered as an important parameter to improve dispersion of silica and for reduction of silica flocculation in the rubber compounds.

Similar content being viewed by others

References

J. T. Byers, Rubber Chem. Technol., 75, 527 (2002).

M. Castellanoa, L. Conzattia, G. Costab, L. Falquib, A. Turturroa, B. Valentia, and F. Negronic, Polymer, 46, 695 (2005).

Y. P. Wu, Q. S. Zhao, S. H. Zhao, and L. Q. Zhang, J. Appl. Polym. Sci., 108, 112 (2008).

S. S. Choi, C. Nah, S. G. Lee, and C. W. Joo, Polym. Int., 52, 23 (2003).

C. J. Lin, W. L. Hergenrother, and A. S. Hilton, Rubber Chem. Technol., 75, 215 (2002).

M. J. Wang, Rubber Chem. Technol., 71, 520 (1998).

S. S. Choi and S. Park, Korea Polym. J., 9, 92 (2001).

P. Sae-oui, C. Sirisinha, U. Thepsuwan, and K. Hatthapanit, Polym. Test., 23, 871 (2004).

A. K. Manna, P. P. De, and D. K. Tripathy, J. Appl. Polym. Sci., 84, 2171 (2002).

H. Yan, G. Tian, K. Sun, and Y. Zhang, J. Appl. Polym. Sci., 43, 573 (2005).

L. A. E. M. Reuvekamp, S. C. Debnath, J. W. Ten Brinke, P. J. Van Swaaij, and J. W. M. Noordermeer, Rubber Chem. Technol., 77, 34 (2004).

H. D. Luginsland, J. Fröhlich, and A. Wehmeier, Rubber Chem. Technol., 75, 563 (2002).

L. A. E. M. Reuvekamp, J. W. Ten Brinke, P. J. Van Swaaij, and J. W. M. Noordermeer, Rubber Chem. Technol., 75, 187 (2002).

T. Sone and T. Yuasa, Nippon Gomu Kyokaishi, 83, 103 (2010).

G. Mannebach, R. Morschhäuser, T. Scholl, and R. Stadler, E. P. Patent 1,165,641A1 (2002).

J. L. Cabioch and G. Labauze, E.P. Patent 0,778,311A1 (1997).

T. Scholl, U. Eisele, J. Trimbach, and S. Kelbch, U.S. Patent 6,252,008 (2001).

T. Scholl and J. Trimbach, U.S. Patent 6,365,668 (2002).

T. Scholl, W. Obrecht, W. Braubach, E. Giebeler, M. Grün, A. Müller, and M. Graf, U.S. Patent 6,518,369 (2003).

H. Kondo and K. Morita, E.P. Patent 1113024 (1999).

M. L. Kerns and S. K. Henning, Rubber Chem. Technol., 75, 299 (2002).

K. A. Blume, Kaut. Gummi Kunstst., 64, 38 (2011).

A. F. Halasa and W. Hsu, Polymer, 43, 7111 (2000).

C. Robertson, C. Lin, R. Bogoslovov, M. Rackaitis, P. Sadhukhan, J. Quinn, and C. Roland, Rubber Chem. Technol., 84, 507 (2011).

D. Derouet, S. Forgeard, and J. Brosee, Macromol. Chem. Phys., 199, 1835 (1998).

D. Derouet, S. Forgeard, and J. Brosee, Macromol. Chem. Phys., 200, 10 (1999).

A. Ansarifar, L. Wang, and R. Ellis, J. Appl. Polym. Sci., 106, 1135 (2007).

A. Ahagon, Rubber Chem. Technol., 69, 742 (1996).

S. S. Choi, Korea Polym. J., 8, 192 (2000).

A. R. Payne, J. Appl. Polym. Sci., 6, 57 (1962).

C. G. Robertson, C. J. Lin, R. B. Bogoslovov, M. Rackaitis, P. Sadhukhan, J. D. Quinn, and C. M. Roland, Rubber Chem. Technol., 84, 507 (2011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Seo, B., Kim, K., Lee, H. et al. Effect of styrene-butadiene rubber with different macrostructures and functional groups on the dispersion of silica in the compounds. Macromol. Res. 23, 466–473 (2015). https://doi.org/10.1007/s13233-015-3055-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-015-3055-8