Abstract

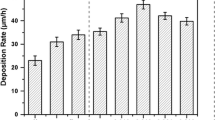

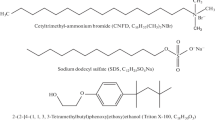

Electroless Ni–P and Ni–P–CuO coating on mild steel was developed successfully with the addition of Zwitterionic surfactant. The usage of nano-CuO in electroless coating was intermittent though the cost is low with high catalytic activity. Zwitterionic surfactant was introduced into the composite coating for the first time to increase the suspension of nanoparticles effectively during the coating process. Surfactant helps to reduce the intermolecular attraction between the solid and liquid interfaces and hence binding of nanoparticles with the hydrogen gas bubbles was eliminated. Also agglomeration of nanoparticles was controlled by stirring the electrolyte continuously using magnetic stirrer. The characterization and tribological properties were tested for the newly developed composites. Scanning electron microscope micrograph reveals the deposits are produced without any defects and the presence of CuO nanoparticles in the deposit. Energy-dispersive spectroscopy measurement shows the changes of weight percentage of elements available in the substrate. The surface roughness of the deposit was improved with the addition of CuO, it packs the gap between two grains and offers smooth finish and as the result the surface properties are modified. Microhardness of the substrate was improved for the substrate added with nano-CuO. The corrosion resistance of the substrate was improved when compared to the substrate produced using electroless Ni–P binary coating. Zwitterionic surfactant reduces the agglomeration of nanoparticles during chemical reaction and allows the particles to coat only on the target. Similarly, this technique can be implemented in the production of other composites in electroless coatings.

Similar content being viewed by others

References

Jadhav, A.J.; Holkar, C.R.; Pinjari, D.V.: Anticorrosive performance of super-hydrophobic imidazole encapsulated hollow zinc phosphate nanoparticles on mild steel. Prog. Org. Coat. 114, 33–39 (2018). https://doi.org/10.1016/j.porgcoat.2017.09.017

Sudagar, J.; Lian, J.; Sha, W.: Electroless nickel, alloy, composite and nano coatings—a critical review. J. Alloys Compd. 571, 183–204 (2013). https://doi.org/10.1016/j.jallcom.2013.03.107

Sudagar, J.; Lian, J.; Bi, G.; Jing, J.; Liu, J.: A new method to prepare MgO and base for further electroless nickel deposition on magnesium substrate. Int. J. Surf. Sci. Eng. 7, 97–108 (2013). https://doi.org/10.1504/IJSURFSE.2013.05369

Hadipour, A.; Monirvaghefi, S.M.; Bahrololoom, M.E.: Electroless deposition of graded Ni–P coatings. Surf. Eng. 31, 399–405 (2015). https://doi.org/10.1179/1743294414Y.0000000430

Parkinson, R.: Properties and applications of electroless nickel. Nickel Dev. Inst. Publ. (1997). https://doi.org/10.1016/j.proeng.2014.12.321

Rabizadeh, T.; Allahkaram, S.R.: Corrosion resistance enhancement of Ni–P electroless coatings by incorporation of nano-SiO\(_{2}\) particles. Mater. Des. 32, 133–138 (2011). https://doi.org/10.1016/j.matdes.2010.06.021

Afroukhteh, S.; Dehghanian, C.; Emamy, M.: Corrosion behavior of Ni–P/nano-TiC composite coating prepared in electroless baths containing different types of surfactant. Prog. Nat. Sci. Mater. Int. 22, 480–487 (2012). https://doi.org/10.1016/j.pnsc.2012.10.005

Alishahi, M.; Monirvaghefi, S.M.; Saatchi, A.; Hosseini, S.M.: The effect of carbon nanotubes on the corrosion and tribological behavior of electroless Ni-P-CNT composite coating. Appl. Surf. Sci. 258, 2439–2446 (2012). https://doi.org/10.1016/j.apsusc.2011.10.067

Ma, H.; Tian, F.; Li, D.; Guo, Q.: Study on the nano-composite electroless coating of Ni–P/Ag. J. Alloys Compd. 474, 264–267 (2009). https://doi.org/10.1016/j.jallcom.2008.06.057

Franco, M.; Sha, W.; Malinov, S.; Liu, H.: Micro-scale wear characteristics of electroless Ni–P/SiC composite coating under two different sliding conditions. Wear 317, 254–264 (2014). https://doi.org/10.1016/j.wear.2014.06.013

Alirezaei, S.; Monirvaghefi, S.M.; Salehi, M.; Saatchi, A.: Wear behavior of Ni–P and Ni–P–Al\(_{2}\)O\(_{3}\) electroless coatings. Wear 262, 978–985 (2007). https://doi.org/10.1016/j.wear.2006.10.013

Banthia, S.; Sengupta, S.; Mallik, M.; Das, S.; Das, K.: Substrate effect on electrodeposited copper morphology and crystal shapes. Surf. Eng. 0, 1–8 (2017). https://doi.org/10.1080/02670844.2017.1321265

Muraliraja, R.; Elansezhian, R.; Sudagar, J.; Raviprakash, A.V.: Influence of a Zwitterionic surfactant on the surface properties of electroless Ni–P coating on mild steel. J. Surfactants Deterg. 19, 1081–1088 (2016). https://doi.org/10.1007/s11743-016-1858-z

Zarebidaki, A.; Allahkaram, S.R.: Effect of surfactant on the fabrication and characterization of Ni-P-CNT composite coatings. J. Alloys Compd. 509, 1836–1840 (2011). https://doi.org/10.1016/j.jallcom.2010.057

Muraliraja, R.; Elansezhian, R.: Effect of zwitterionic surfactant on tribological behaviour of electroless plating. Surf. Eng. 30, 752–757 (2014). https://doi.org/10.1179/1743294414Y.0000000321

Ansari, M.I.; Thakur, D.G.: Influence of surfactant: using electroless ternary nanocomposite coatings to enhance the surface properties on AZ91 magnesium alloy. Surf. Interfaces 7, 20–28 (2017). https://doi.org/10.1016/j.surfin.2017.02.004

Muraliraja, R.; Elansezhian, R.: Proceedings of Malaysian International Tribology Conference 2015—Google Books. https://books.google.com.om/books?hl=en&lr=&id=KSDNCgAAQBAJ&oi=fnd&pg=PA316&dq=info:2jubDA3oXdkJ:scholar.google.com&ots=snivkjyblT&sig=MQ5by_1bf2b5N63Z3xVDsXk3OcE&redir_esc=y#v=onepage&q&f=false

Chen, B.-H.; Hong, L.; Ma, Y.; Ko, T.-M.: Effects of surfactants in an electroless nickel-plating bath on the properties of Ni–P alloy deposits. Ind. Eng. Chem. Res. 41, 2668–2678 (2002). https://doi.org/10.1021/ie0105831

Mai, Q.X.; Daniels, R.D.; Harpalani, H.B.: Structural changes induced by heating in electroless nickel–phosphorus alloys. Thin Solid Films 166, 235–247 (1988). https://doi.org/10.1016/0040-6090(88)90384-7

Elansezhian, R.; Ramamoorthy, B.; Nair, P.K.: The influence of SDS and CTAB surfactants on the surface morphology and surface topography of electroless Ni–P deposits. J. Mater. Process. Technol. 209, 233–240 (2009). https://doi.org/10.1016/j.jmatprotec.2008.01.057

Elansezhian, R.; Ramamoorthy, B.; Nair, P.K.: Influence of surfactants on the tribological behaviour of electroless Ni–P coatings. Int. J. Surf. Sci. Eng. 4, 258–268 (2010). https://doi.org/10.1504/IJSURFSE.2010.033253

Shakoor, R.A.; Kahraman, R.; Waware, U.S.; Wang, Y.; Gao, W.: Synthesis and properties of electrodeposited Ni–B–CeO\(_{2}\) composite coatings. Mater. Des. 59, 421–429 (2014). https://doi.org/10.1016/j.matdes.2014.03.024

Subakova, I.; Petukhov, I.; Medvedeva, N.: Obtaining of Ni–P–TiO\(\backslash \)n 2\(\backslash \)n composite coatings with TiO\(\backslash \)n 2\(\backslash \)n sol and surfactants and their properties. Mater. Manuf. Process. 6914, 141223092238008 (2014). https://doi.org/10.1080/10426914.2014.994756

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Muraliraja, R., Sudagar, J., Elansezhian, R. et al. Estimation of Zwitterionic Surfactant Response in Electroless Composite Coating and Properties of Ni–P–CuO (Nano)Coating. Arab J Sci Eng 44, 821–828 (2019). https://doi.org/10.1007/s13369-018-3300-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-018-3300-5