Abstract

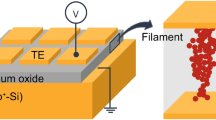

The unique nonlinear relationship between charge and magnetic flux along with the pinched hysteresis loop in I-V plane provide memory with resistance combinations of attribute to Memristor which lead to their novel applications in non volatile memory, nonlinear dynamics, analog computations and neuromorphic biological systems etc. The present paper reports development of Ag/WO3/ITO thin film memristor device using spray pyrolysis method. The structural, morphological and electrical properties of the thin film memristor device are further characterized using x-ray diffraction (XRD), Scanning Electron Microscopy (SEM), and semiconductor device analyzer. The memristor is simulated using linear dopent drift model to ascertain the theoretical and experimental conformations. For the simulation purpose, the width of doped region (w) limited to the interval [0, D] is considered as a state variable along with the window function characterized by the equation f (x) = w (1 − w). The reported memristor device exhibits the symmetric pinched hysteresis loop in I-V plane within the low operating voltage (±1 V).

Similar content being viewed by others

References

L. O. Chua, IEEE Trans. Circuit. Theory 18, 507 (1971).

D. B. Strukov, G. S. Snider, D. R. Stewart, and R. S. Williams, Nature 453, 80 (2008).

K. H. Kim, S. Gaba, D. Wheeler, J. M. Cruz-Albrecht, T. Hussain, N. Srinivasa, and W. Lu, Nano Lett. 12, 389 (2011).

J. J. Yang, M. D. Pickett, X. Li, D. A. Ohlberg, D. R. Stewart, and R. S. Williams, Nature Nanotechnol. 3, 429 (2008).

B. Muthuswamy, Int. J. Bifurcat. Chaos. 20, 335 (2010).

M. Itoh and L. Chua, Int. J. Bifurcat. Chaos. 18, 3183 (2008).

T. D. Dongale, Health Inform.-Int. J. 2, 15 (2013).

S. H. Jo, T. Chang, I. Ebong, B. B. Bhadviya, P. Mazumder, and W. Lu, Nano Lett. 10, 1297 (2010).

Y. N. Joglekar and S. J. Wolf, Eur. J. Phys. 30, 661 (2009).

T. A. Wey and S. Benderli, Electron. Lett. 45, 1103 (2009).

Q. Xia, W. Robinett, M. W. Cumbie, N. Banerjee, T. J. Cardinali, J. J. Yang, and R. S. Williams, Nano Lett. 9, 3640 (2009).

Y. V. Pershin and M. Di Ventra, Phys. Rev. B. 78, 113309 (2008).

T. D. Dongale, S. S. Shinde, R. K. Kamat, and K. Y. Rajpure, J. Alloy. Compd. 593, 267 (2014).

S. Yoon, J. S. Choi, Y. S. Kim, S. H. Hong, I. R. Hwang, Y. C. Park, and B. H. Park, Appl. Phys. Express 4, 041101 (2011).

S. E. Savel’Ev, A. S. Alexandrov, A. M. Bratkovsky, and R. S. Williams, Nanotechnology 22, 254011 (2011).

S. Kim, S. Choi, and W. Lu, ACS Nano. 8, 2369 (2014).

X. He, Y. Yin, J. Guo, H. Yuan, Y. Peng, Y. Zhou, and D. Tang, Nanoscale Res. Lett. 8, 1 (2013).

R. Zhang, S. U. Yuldashev, J. C. Lee, V. S. alishev, T. W. Kang, and D. J. Fu, Microelectron. Eng. 112, 31 (2013).

L. Ying-Tao, L. Shi-Bing, L. Hang-Bing, L. Qi, W. Qin, W. Yan, and L. Ming, Physica B. 20, 017305 (2011).

L. Chua, Appl. Phys. A Mater. Sci. Process 102, 765 (2011).

Y. Li, S. Long, Q. Liu, Q. Wang, M. Zhang, H. Lv, and M. Liu, Phys. Status Solidi-RRL 4, 124 (2010).

P. S. Patil, Mater. Chem. Phys. 59, 185 (1999).

V. V. Ganbavle, G. L. Agawane, A. V. Moholkar, J. H. Kim, and K. Y. Rajpure, J. Mater. Eng. Perform. 23, 1204 (2014).

S. V. Mohite and K. Y. Rajpure, Opt. Mater. 36, 833 (2014).

K. H. Choi, M. Mustafa, K. Rahman, B. K. Jeong, and Y. H. Doh, Appl. Phys. A Mater. Sci. Process. 106, 165 (2012).

T. D. Dongale, K. P. Patil, S. B. Mullani, K. V. More, S. D. Delekar, P. S. Patil, P. K. Gaikwad, and R. K. Kamat, Mat. Sci. Semicon. Proc. 35, 174 (2015).

T. D. Dongale, K. P. Patil, P. K. Gaikwad, and R. K. Kamat, Mat. Sci. Semicon. Proc. 38, 228 (2015).

S. S. Shinde and T. D. Dongle, J. Semicond. 36, 034001 (2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dongale, T.D., Mohite, S.V., Bagade, A.A. et al. Development of Ag/WO3/ITO thin film memristor using spray pyrolysis method. Electron. Mater. Lett. 11, 944–948 (2015). https://doi.org/10.1007/s13391-015-4180-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-015-4180-4