Abstract

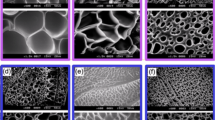

A silicone rubber-based biochip for disinfection under deep-UV light exposure was successfully fabricated by an ArF excimer laser. To fabricate the biochip, periodic micro-swelling structure of silicone rubber was photochemically formed by the ArF excimer laser-induced photodissociation of Si–O bonds of silicone rubber. It was found that the growth rate of the micro-swelling structure could be controlled by varying the laser pulse repetition rate; a slow growth of roughly 100 ms and longer per laser pulse was recognized. In addition, no change of each the micro-swelling height formed at various laser pulse repetition rates was also found in the range of 300–18,000 of laser pulse number. Using such the wide processing window, moreover, the periodic micro-swelling structure could be modified into photoluminescent property by long irradiation of ArF excimer laser, while maintaining the micro-swelling height. Blue photoluminescence from the modified micro-swelling structure was observed under a deep-UV light exposure. Thus, each the periodic micro-swelling structure with various desired heights could be bonded to a flat plate of fused silica glass to have equal gaps. A small amount of solution could be confined in the equal gap to disinfect virus/bacteria in the solution under deep-UV light for analytical application.

Graphic Abstract

Similar content being viewed by others

References

Zuo, P., Li, X.-J., Dominguezc, D.C., Yeb, B.-C.: A PDMS/paper/glass hybrid microfluidic biochip integrated with aptamer-functionalized graphene oxide nano-biosensors for one-step multiplexed pathogen detection. Lab Chip 13, 3921–3928 (2013)

Kim, K., Park, S.W., Yang, S.S.: The optimization of PDMS-PMMA bonding process using silane primer. BioChip J. 4, 148–154 (2010)

Beh K.K., Samsuri F., Lee T.P., Mohamed K.: The fabrication of PDMS mould for microelectrode array biochip using NIL. IOP Conf. Series: Materials Science and Engineering 114, 012026/1–11 (2016)

Urai, H., Makimura, T., Ogawa, M.: Micrometer-scale photo-direct machining of polydimethylsiloxane using laser plasma EUV radiations. In: Kawachi, T., Bulanov, S.V., Daido, H., Kato, Y. (eds.) X-Ray Lasers 2016. ICXRL 2016. Springer Proceedings in Physics, vol. 202, pp. 383–386. Springer, Cham (2018)

Obata, K., Slobin, S., Schonewille, A., Hohnholz, A., Unger, C., Koch, J., Suttmann, O., Overmeyer, L.: UV laser direct writing of 2D/3D structures using photo-curable polydimethylsiloxane (PDMS). Appl. Phys. A 123, 495 (2017)

Hohnholz, A., Obata, K., Nakajima, Y., Koch, J., Terakawa, M., Suttmann, O., Overmeyer, L.: Hybrid UV laser direct writing of UV-curable PDMS thin film using aerosol jet printing. Appl. Phys. A 125, 120 (2019)

Naruse, T., Hanada, Y.: Rapid, high-quality microfabrication of thermoset polymer PDMS using laser-induced bubbles. Opt. Express 27, 9429–9438 (2019)

Nakajima, Y., Obata, K., Machida, M., Hohnholz, A., Koch, J., Suttmann, O., Terakawa, M.: Femtosecond-laser-based fabrication of metal/PDMS composite microstructures for mechanical force sensing. Opt. Mater. Express 7, 4203–4213 (2017)

Okoshi, M., Pambudi, W.S.: Fabrication of superhydrophobic silicone rubber by ArF-excimer-laser-induced microstructuring for repelling water in water. Appl. Phys. Express 9, 112701 (2016)

Nojiri, H., Pambudi, W.S., Okoshi, M.: Formation of periodic micro-swelling structures on silicone rubber surface by ArF excimer laser to realize superhydrophobic property. Jpn. J. Appl. Phys. 56, 072002 (2017)

Takao, H., Okoshi, M., Inoue, N.: Fabrication of SiO2-humps on silicone rubber using F2 laser. Jpn. J. Appl. Phys. 41, L1088–L1089 (2002)

Okoshi, M., Kimura, T., Takao, H., Inoue, N., Yamashita, T.: Photochemical modification of silicone films using F2 laser for selective chemical etching. Jpn. J. Appl. Phys. 43, 3438–3442 (2004)

Takao, H., Okoshi, M., Inoue, N.: Swelling and modification of silicone surface by F2 laser irradiation. Appl. Phys. A 79, 1571–1574 (2004)

Takao, H., Okoshi, M., Miyagami, H., Inoue, N.: Fabrication of SiO2 microlenses on silicone rubber using a vacuum-ultraviolet F2 laser. IEEE J. Sel. Top. Quant. 10, 1426–1429 (2004)

Okoshi, M., Awaihara, Y., Yamashita, T., Inoue, N.: F2-laser-induced micro/nanostructuring and surface modification of iron thin film to realize hydrophobic and corrosion resistant. Jpn. J. Appl. Phys. 53, 112701 (2014)

Okoshi, M.: Fabrication of superhydrophobic silicone rubber operating in water. Appl. Phys. Express 11, 101801 (2018a)

Okoshi, M.: Formation of textured Al thin film on silicone rubber to obtain superhydrophobic property. SN Appl. Sci. 1, 133/1–7 (2018b)

Okoshi, M.: Fabrication of silicone rubber periodic micro-suction cup structures using a 193 nm ArF excimer laser. Appl. Phys. Express 12, 062012 (2019a)

Okoshi, M.: Fabrication of superhydrophobic silicone rubber with periodic micro/nano-suction cup structure by ArF excimer laser-induced photodissociation. Nanomaterials 9, 870/1–12 (2019b)

Okoshi, M.: Micro/nano-suction cup structure of silicone rubber fabricated by ArF excimer laser. SN Appl. Sci. 1, 1330 (2019c)

Okoshi, M., Sekine, D., Inoue, N., Yamashita, T.: White-light emission from silicone rubber modified by 193 nm ArF excimer laser. Jpn. J. Appl. Phys. 46, L356–L358 (2007)

Okoshi, M., Iyono, M., Inoue, N.: Photochemical surface modification of silicone rubber into photoluminescent material by 193 nm ArF excimer laser irradiation. Jpn. J. Appl. Phys. 48, 102301 (2009a)

Okoshi, M., Iyono, M., Inoue, N.: Controllable change of photoluminescence spectra of silicone rubber modified by 193 nm ArF excimer laser. Jpn. J. Appl. Phys. 48, 122503 (2009b)

Okoshi, M., Iyono, M., Inoue, N., Yamashita, T.: Wavelength dependence of photochemical surface modification of silicone rubber. J. Kor. Phys. Soc. 54, 1203–1206 (2009)

Okoshi, M., Cho, J., Inoue, N.: F2 laser photochemical welding of aligned silica microspheres to silicone rubber. Jpn. J. Appl. Phys. 46, 1516–1520 (2007a)

Okoshi, M., Cho, J., Inoue, N.: Photochemical bonding of aligned silica microspheres by F2 laser induced chemical vapor deposition. Jpn. J. Appl. Phys. 46, 6658–6662 (2007b)

Okoshi, M., Li, J., Herman, P.R., Inoue, N.: Photochemical welding of silica optical components to silicone rubber by F2 laser. J. Phys. Conf. Ser. 59, 712–715 (2007)

Acknowledgements

We thank Mr. Misaki Yokoyama for experiment assistance. This work was supported by JSPS KAKENHI Grant Number JP18K04790.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Okoshi, M., Yoshida, T. Fabrication of Silicone Rubber-Based Biochip for Disinfection Under Deep-UV Light by ArF Excimer Laser-Induced Photodissociation. Electron. Mater. Lett. 17, 68–73 (2021). https://doi.org/10.1007/s13391-020-00261-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-020-00261-w