Abstract

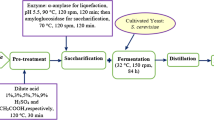

Macroalgae are considered to be one of the rich lignocellulosic biomass materials. Aquatic biomass has gained more attention to biofuels generation in recent years due to its renewable, abundant, and environmentally friendly aspects. Macroalgae are photosynthetic organisms that are found in both marine and freshwater environments. These are considered as a third-generation feedstock for the production of biofuels since they have the ability to synthesize a high amount of lipids, proteins, and carbohydrates. This research study aimed to evaluate the potential of bioethanol production from macroalgae (Rhizoclonium sp.) biomass. The fermentation process was applied in the research by two-way separate hydrolysis and fermentation (SHF). Algae biomass undergoes a pretreatment process to release necessary sugars for yeast digestion. The fermentation process was carried at 30 to 35 °C in the incubator. Finally, the percentage of ethanol was estimated by the ebulliometer. Fermentation was enhanced by immobilization of yeast, which showed the highest concentration of ethanol (65.43 ± 18.13 g/l) after 96 h of fermentation and can be reused for several times for fermentation. Moreover, these study results confirmed that freshwater macroalgae biomass is a suitable and susceptible raw material for bioethanol production.

Similar content being viewed by others

References

Bhuyar P, Sathyavathi S, Math RK (2020) Production of bioethanol from starchy tuber (Amorphophallus commutatus) and antimicrobial activity study of its extracts. African J Biol Sci 2:70–76

Annam Renita A, Sreedhar N, Magesh Peter D (2014) Optimization of algal methyl esters using RSM and evaluation of biodiesel storage characteristics. Bioresour Bioprocess 1:1–9

Bhuyar P, Yusoff MM, Ab Rahim MH, Sundararaju S, Maniam GP, Govindan N (2020) Effect of plant hormones on the production of biomass and lipid extraction for biodiesel production from microalgae Chlorella sp. J Microbiol Biotechnol Food Sci 9:4. https://doi.org/10.15414/jmbfs.2020.9.4.671-674

Ramaraj R, Tsai DDW, Chen PH (2014) An exploration of the relationships between microalgae biomass growth and related environmental variables. J Photochem Photobiol B Biol 135:44–47

Ramaraj R, Unpaprom Y (2019) Optimization of pretreatment condition for ethanol production from Cyperus difformis by response surface methodology. 3. Biotech 9:1–9

Norjannah B, Ong HC, Masjuki HH, Juan JC, Chong WT (2016) Enzymatic transesterification for biodiesel production: a comprehensive review. RSC Adv 6:60034–60055

Chisti Y (2008) Biodiesel from microalgae beats bioethanol. Trends Biotechnol 26:126–131

Vu PT, Unpaprom Y, Ramaraj R (2017) Evaluation of bioethanol production from rice field weed biomass. Emergent Life Sci Res 3:42–49

Vu PT, Unpaprom Y, Ramaraj R (2018) Impact and significance of alkaline-oxidant pretreatment on the enzymatic digestibility of Sphenoclea zeylanica for bioethanol production. Bioresour Technol 247:125–130

Saengsawang B, Bhuyar P, Manmai N, Ponnusamy VK, Ramaraj R, Unpaprom Y (2020) The optimization of oil extraction from macroalgae, Rhizoclonium sp. by chemical methods for efficient conversion into biodiesel. Fuel 274:117841

Bhuyar P, Rahim MH, Yusoff MM, Gaanty Pragas Maniam NG (2019) A selective microalgae strain for biodiesel production in relation to higher lipid profile. Maejo Int J Energy Environ Commun 1:8–14

Ramaraj R, Tsai DDW, Chen PH (2014) Freshwater microalgae niche of air carbon dioxide mitigation. Ecol Eng 68:47–52

Mukherjee P, Ahmad A, Mandal D, Senapati S, Sainkar SR, Khan MI, Parishcha R, Ajaykumar PV, Alam M, Kumar R, Sastry M (2001) Fungus-mediated synthesis of silver nanoparticles and their immobilization in the mycelial matrix: a novel biological approach to nanoparticle synthesis. Nano Lett 1:515–519

Ramaraj R, Unpaprom Y (2019) Enzymatic hydrolysis of small-flowered nutsedge (Cyperus difformis) with alkaline pretreatment for bioethanol. Maejo Int J Sci Technol 13:110–120

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48:3713–3729

Bhuyar P, Sundararaju S, Rahim MH, Ramaraj R, Maniam GP, Govindan N (2019) Microalgae cultivation using palm oil mill effluent as growth medium for lipid production with the effect of CO2 supply and light intensity. Biomass Convers Biorefine. https://doi.org/10.1007/s13399-019-00548-5

Anjum S, Abbasi BH, Shinwari ZK (2016) Plant-mediated green synthesis of silver nanoparticles for biomedical applications: challenges and opportunities. Pak J Bot 48:1731–1760

Kumar R, Strezov V, Weldekidan H, He J, Singh S, Kan T, Dastjerdi B (2020) Lignocellulose biomass pyrolysis for bio-oil production: a review of biomass pretreatment methods for production of drop-in fuels. Renew Sust Energ Rev 123:109763. https://doi.org/10.1016/j.rser.2020.109763

Zabed H, Sahu JN, Suely A, Boyce AN, Faruq G (2017) Bioethanol production from renewable sources: current perspectives and technological progress. Renew Sust Energ Rev 71:475–501

Bhuyar P, Tamizi NA, Rahim MH, Pragas G, Maniam NG (2019) Desalination of polymer and chemical industrial wastewater by using green photosynthetic microalgae, Chlorella sp. Maejo Int J Energy Environ Commun 1:9–19

Wannapokin A, Ramaraj R, Whangchai K, Unpaprom Y (2018) Potential improvement of biogas production from fallen teak leaves with co-digestion of microalgae. 3. Biotech 8:1–18

Sarris D, Papanikolaou S (2016) Biotechnological production of ethanol: biochemistry, processes and technologies. Eng Life Sci 16:307–329

Willaert R, Nedovic VA (2006) Primary fermentation of beer with immobilized yeast—a review on flavour formation and control strategies. J Chem Technol 81(8):1353–1367

Zhao XQ, Bai FW (2009) Yeast flocculation: new story in fuel ethanol production. Biotechnol Adv 27(6):849–856

Stolarzewicz I, Białecka-Florjańczyk E, Majewska E, Krzyczkowska J (2011) Immobilization of yeast on polymeric supports. Chem Biochem Eng Q 25(1):135–144

Bhuyar P, Rahim MHA, Sundararaju S, Ramaraj R, Maniam GP, Govindan N (2020) Synthesis of silver nanoparticles using marine macroalgae Padina sp. and its antibacterial activity towards pathogenic bacteria. Beni-Suef Univ. Aust J Basic Appl Sci 9:9. https://doi.org/10.1186/s43088-019-0031-y

Soumiya S, Baskar G (2017) Macroalgae: source for sustainable production of biodiesel. Int J Ind Eng 1:1–7

He Z, Saw WL, Lane DJ, van Eyk PJ, de Nys R, Nathan GJ, Ashman PJ (2020) The ash-quartz sand interaction behaviours during steam gasification or combustion of a freshwater and a marine species of macroalgae. Fuel 263:116621

Tipnee S, Ramaraj R, Unpaprom Y (2015) Nutritional evaluation of edible freshwater green macroalga Spirogyra varians. Emer Life Sci Res 1(2):1–7

Adeniyi OM, Azimov U, Burluka A (2018) Algae biofuel: current status and future applications. Renew Sust Energ Rev 90:316–335

Yenjit P, Issarakraisila M, Intana W, Chantrapromma K (2010) Fungicidal activity of compounds extracted from the pericarp of Areca catechu against Colletotrichum gloeosporioides in vitro and in mango fruit. Postharvest Biol Technol 55:129–132

Oliveira DA, Angonese M, Ferreira SRS, Gomes L (2017) Food and bioproducts processing nanoencapsulation of passion fruit by-products extracts for enhanced antimicrobial activity. Food Bioprod Process 104:137–146

Manmai N, Unpaprom Y, Ramaraj R (2020) Bioethanol production from sunflower stalk: application of chemical and biological pretreatments by response surface methodology (RSM). Biomass Convers Biorefine. https://doi.org/10.1007/s13399-020-00602-7

Vaithanomsat P, Apiwatanapiwat W, Chumchuent N et al (2011) The potential of coconut husk utilization for bioethanol production. Kasetsart J (Nat Sci) 45:159–164

Mishra A, Kavita K, Jha B (2011) Characterization of extracellular polymeric substances produced by micro-algae Dunaliella salina. Carbohydr Polym 83:852–857

Sivaprakash G, Mohanrasu K, Ananthi V, Jothibasu M, Nguyen DD, Ravindran B, Chang SW, Nguyen-Tri P, Tran NH, Sudhakar M, Gurunathan K, Arokiyaraj S, Arun A (2019) Biodiesel production from Ulva linza, Ulva tubulosa, Ulva fasciata, Ulva rigida, Ulva reticulate by using Mn2ZnO4 heterogenous nanocatalysts. Fuel 255:115744

Shankar K, Kulkarni NS, Jayalakshmi SK, Sreeramulu K (2019) Saccharification of the pretreated husks of corn, peanut and coffee cherry by the lignocellulolytic enzymes secreted by Sphingobacterium sp. ksn for the production of bioethanol. Biomass Bioenergy 127:105298

Miezah K, Obiri-Danso K, Kádár Z, Heiske S, Fei-Baffoe B, Mensah M, Meyer AS (2017) Municipal solid waste management in a low income economy through biogas and bioethanol production. Waste Biomass Valori 8:115–127

Acknowledgments

The authors gratefully acknowledged the Program in Biotechnology, Energy Research Center, School of Renewable Energy, Maejo University, Chiang Mai, Thailand, for the research facilities to accomplish this experimental study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khammee, P., Ramaraj, R., Whangchai, N. et al. The immobilization of yeast for fermentation of macroalgae Rhizoclonium sp. for efficient conversion into bioethanol. Biomass Conv. Bioref. 11, 827–835 (2021). https://doi.org/10.1007/s13399-020-00786-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00786-y